1/What Is Coil Slitting Line?

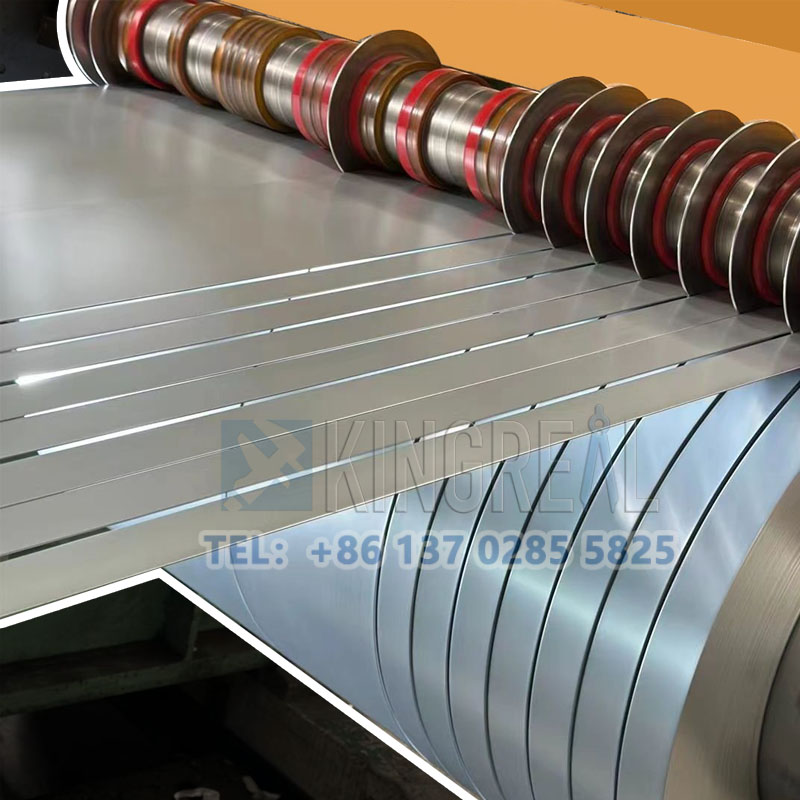

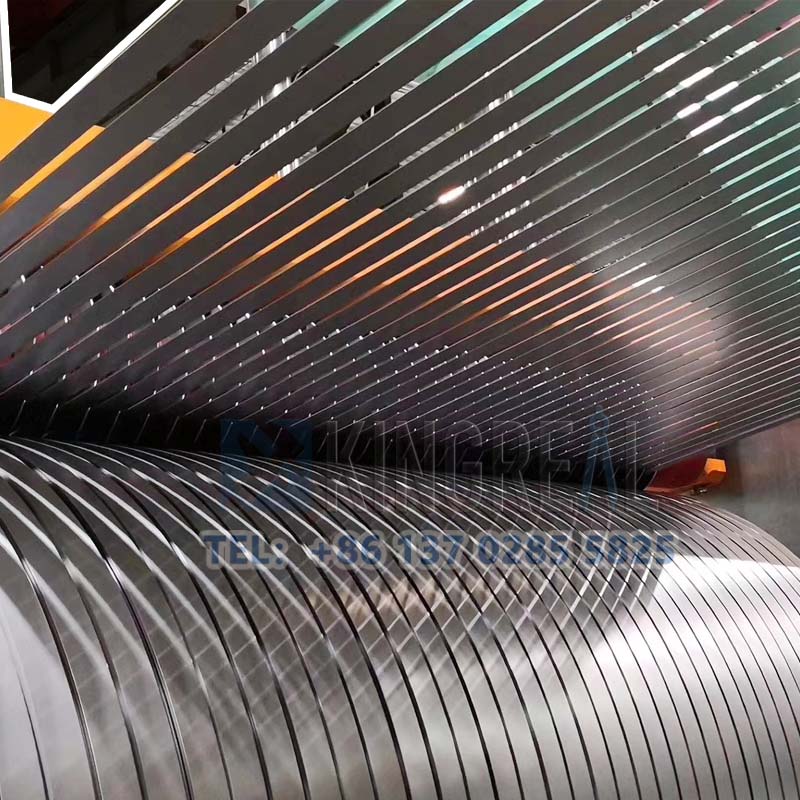

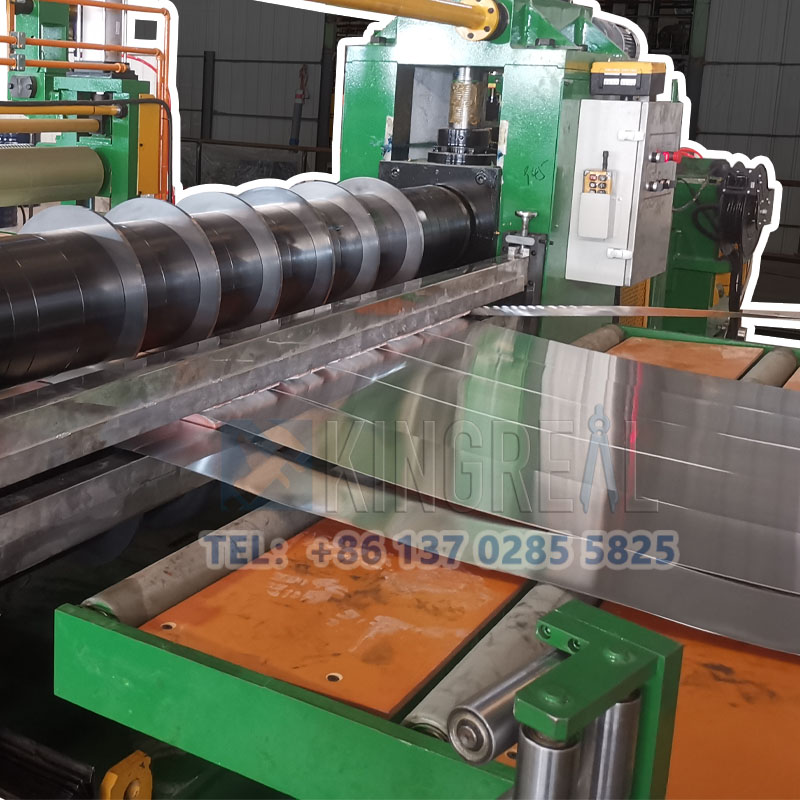

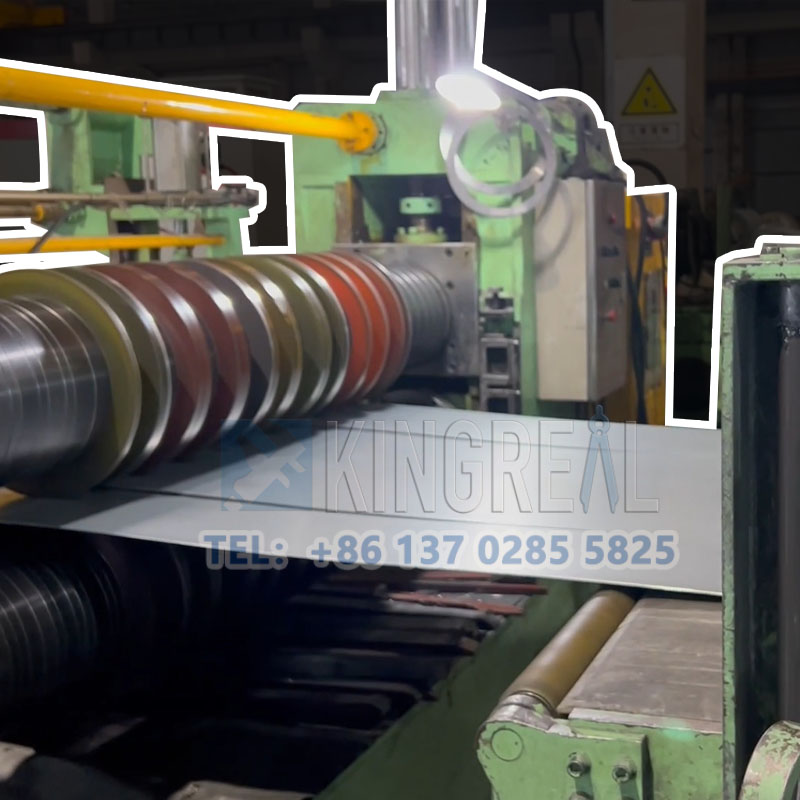

Coil Slitting Line is a precision coil processing line used for cutting wide metal coils, such as aluminum coils, steel coils, stainless steel coils, silicon steel, tinplate and other raw materials into multiple narrow steel strips along the longitudinal direction. Steel coil slitting machine processing of narrow metal coils are usually widely used in welded pipe, cold-formed steel, automobile manufacturing, transformer and other industries, to help each industry according to the actual production needs of metal coil precision processing slitting.

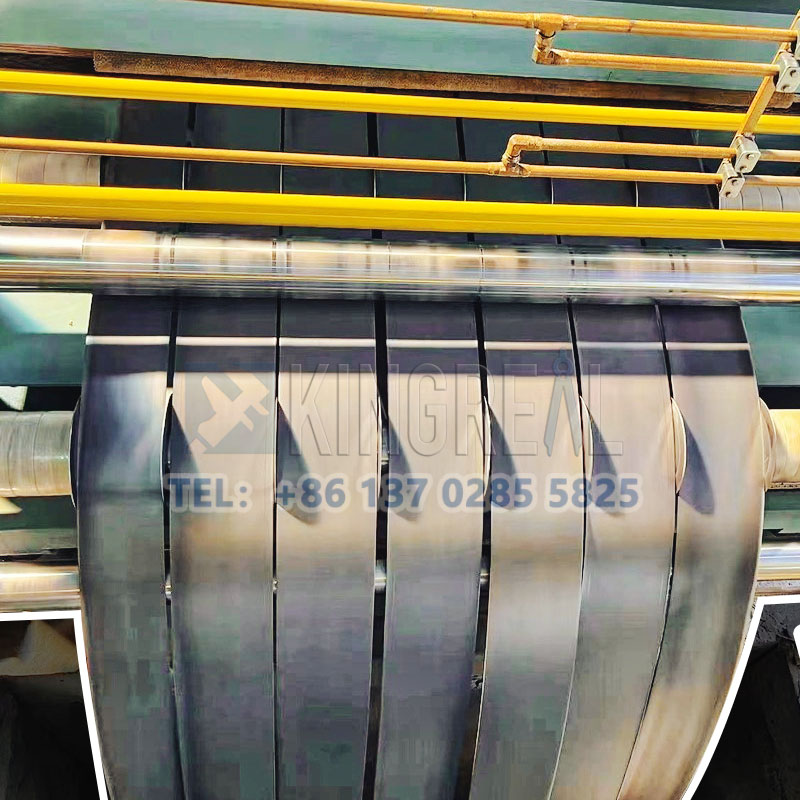

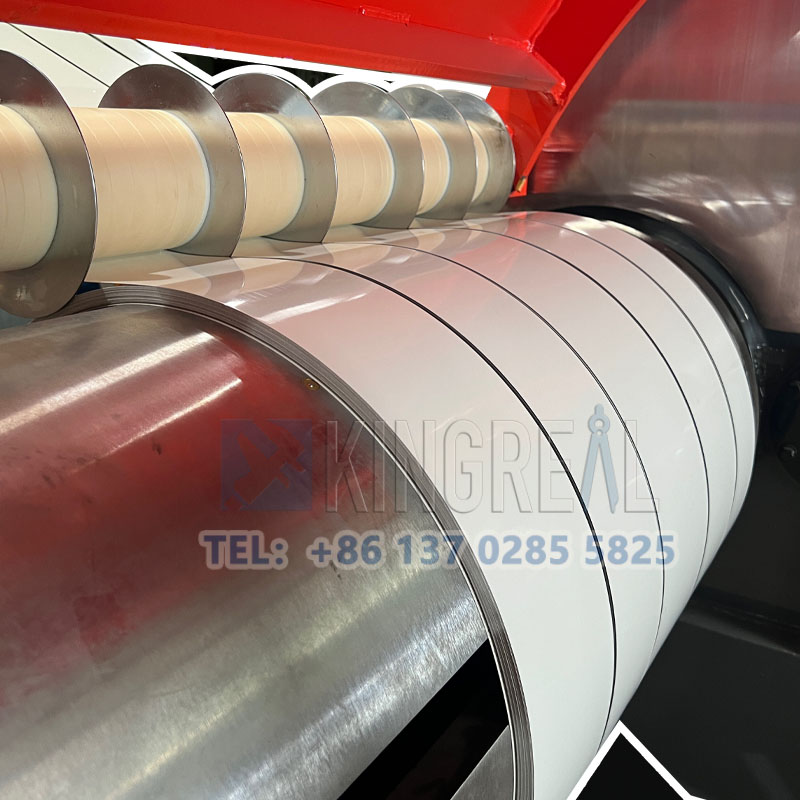

The coil slitting line through the metal coil uncoiling, straightening and leveling process, complete the raw material pretreatment to eliminate bending stress of the coil, to ensure shear precision, followed by the coil slitter through the wide coil slitting for the required width of the narrow strip, and finally through the metal slitting machine tension control and winding machine will be slit after the narrow strip rewinding, to facilitate the subsequent processing. Finally, the slit narrow strip is rewound by metal slitter tension control and winder for subsequent processing.

2/Common Coil Slitting Line Classifications

“Often the classification of COIL SLITTING LINE needs to be based on a number of factors such as the raw material of the coil, its thickness, its width as well as the actual processing output and plant layout.”

Coil Slitting Line Classification By Material Thickness

Light Gauge Steel Slitting Machine

Light Gauge Steel Slitting Machine is suitable for metal coil thickness range of 0.3-3M, common metal raw materials including tinplate, galvanized sheet, etc.

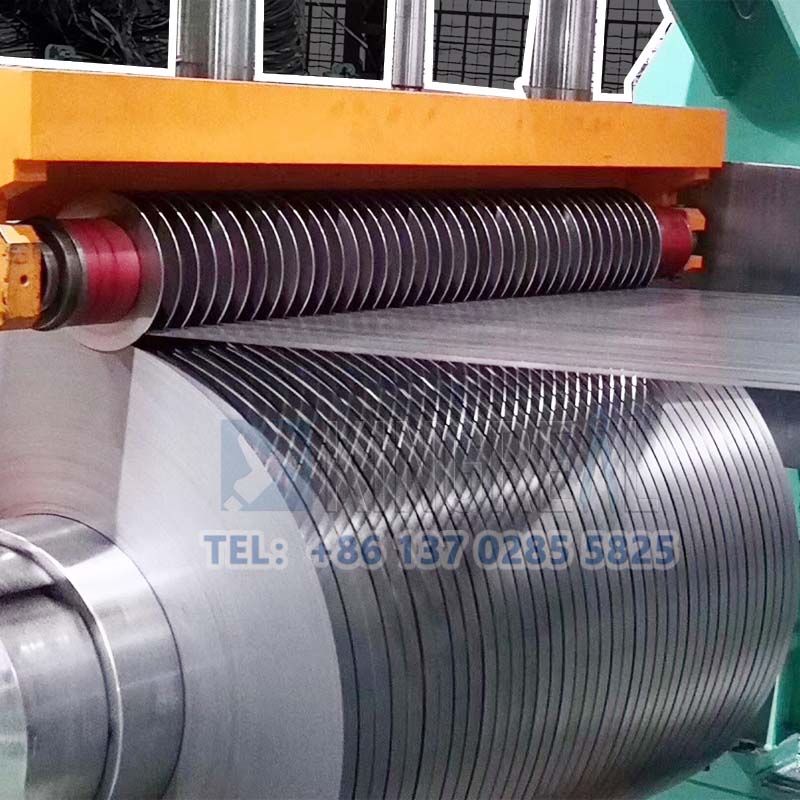

Heavy Gauge Steel Slitting Machine

The Heavy Gauge Steel Slitting Line most important production feature is the ability to process thick or heavy gauge materials up to 20mm thick and 2000mm wide. Metal slitting machines for large coils require high-strength tools and leveling systems to meet the demands of slitting hot rolled coils.

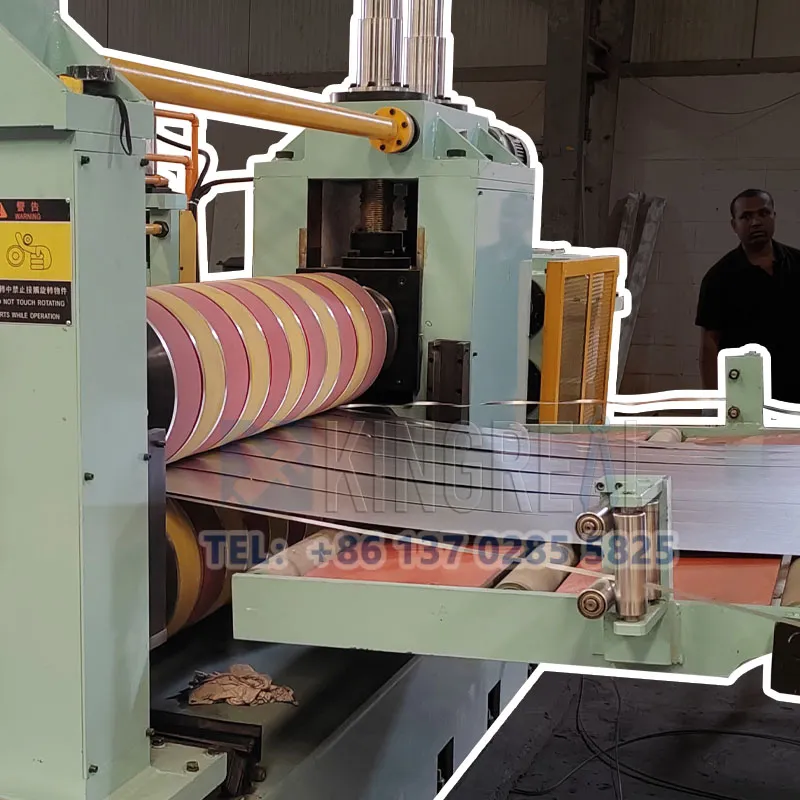

Coil Slitting Machine Classification By Material Suitability

Stainless steel slitting line: corrosion-resistant blade design, adapted to high hardness stainless steel slitting.

Copper/Aluminum Strip Slitting Line: Precision disc shears are used to prevent soft metal edge burrs.

Silicon steel metal slitting machine:Is used to process silicon steel coils into specified widths in accordance with customer's production requirements, usually applied in transformer and other industries. In order to ensure the precision of slitting, the silicon steel metal slitting machine adjusts the coil tension by pneumatic or hydraulic pressure to prevent material slippage, deflection or edge burr during the slitting process.

Classification According To Coil Slitter Production Characteristics

Dual Slitter Head Slitting Line:The core design feature is equipped with two sets of independent slitting and processing knife blocks, which can be used alternately to synchronize production and knife change, significantly reducing downtime and improving processing efficiency.

The Dual Slitter Head Slitting Line is the optimal solution for coil processing plants that require high throughput and efficiency in coil processing.

Compact Coil Slitting Line: The Compact Metal Slitter reduces the length of the entire line by means of a deletion device to help the customer reduce production costs and the footprint of the coil slitting line, while ensuring that the metal slitting process is maintained. It is the best choice for small processing shops and factories with small production requirements.

3/What Is Advantage Of Coil Slitting Line?

1. Meeting The Processing Needs Of A Wide Range Of Raw Materials.

KINGREAL SLITTING coil slitting line can process cold rolled/hot rolled carbon steel, silicon steel, stainless steel, aluminum, galvanized sheet, copper strip and other metal coils, thickness range covering 0.15-12mm. through the replacement of the combination of cutting tools, compartments, the slitting width can be adjusted up to 20-2000mm to meet the customized needs of different industries (such as automotive, home appliances.), Packaging) customized needs.

2. Helping Customers Improve Processing Productivity

KINGREAL SLITTING coil slitting machine realizes unmanned operation and 30%-50% increase in production efficiency through the design of automation of the whole process of unwinding, leveling, slitting and winding (e.g. PLC control system and servo drive).

Dual slitter head slitting machine supports offline tool pre-setting, reducing tool change time by more than 50% and adapting to the needs of multi-specification orders.

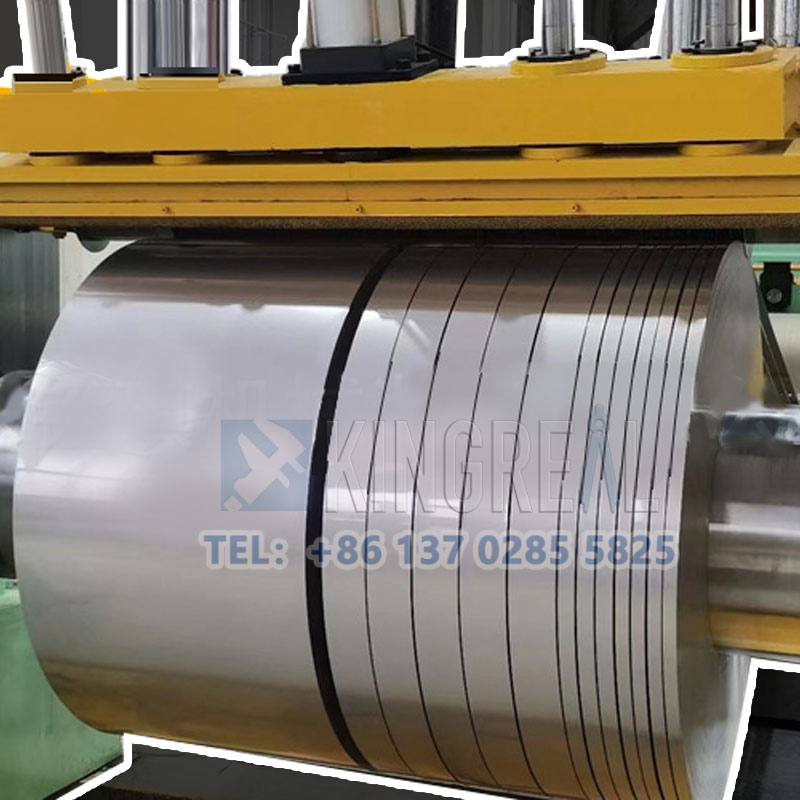

3. Ensure Precision Slitting Process

KINGREAL SLITTING metal slitting machine adopts cemented carbide disc shear with gap adjusting device, which can ensure that the error of slitting width can be controlled within ±0.1mm, edge burr ≤0.02mm, straightness ≤0.1mm/m.

Meanwhile, the metal slitting line can monitor the material position in real time with belt/airbag tension device and photoelectric sensors to prevent deflection or slippage and ensure slitting uniformity.

4. Structural Stability Improves Production Life

The base of the coil slitter is made of steel plate welded and aging treated, the knife shaft is forged from 40Cr and hard chrome plated to ensure long term stability.KINGREAL SLITTING The lubrication points of the metal slitter are centrally managed, e.g. the slitting guide rollers and the knives can be quickly dismantled and replaced, and the daily maintenance is only a matter of cleaning and lubrication.

4/How to choose Coil Slitting Line?

“On the suggestion of how to choose a metal slitting machine, two dimensions need to be considered, the first is the processing demand of raw materials, and the second is the production capacity of the supplier. Clearly their own coil processing needs and professional suppliers to check the technical requirements, can help us get a clear production solutions, access to long-lasting production benefits.”

1. Determine the material characteristics (coil raw material, thickness, width, coil weight, etc.)

2. Determine the production efficiency requirements (slitting width, slitting speed, etc.)

3. Budget and maintenance costs (fully automated metal slitting line has high initial investment, but long-term savings in labor costs; semi-automatic metal slitting line is suitable for companies with limited budget).