Video Display

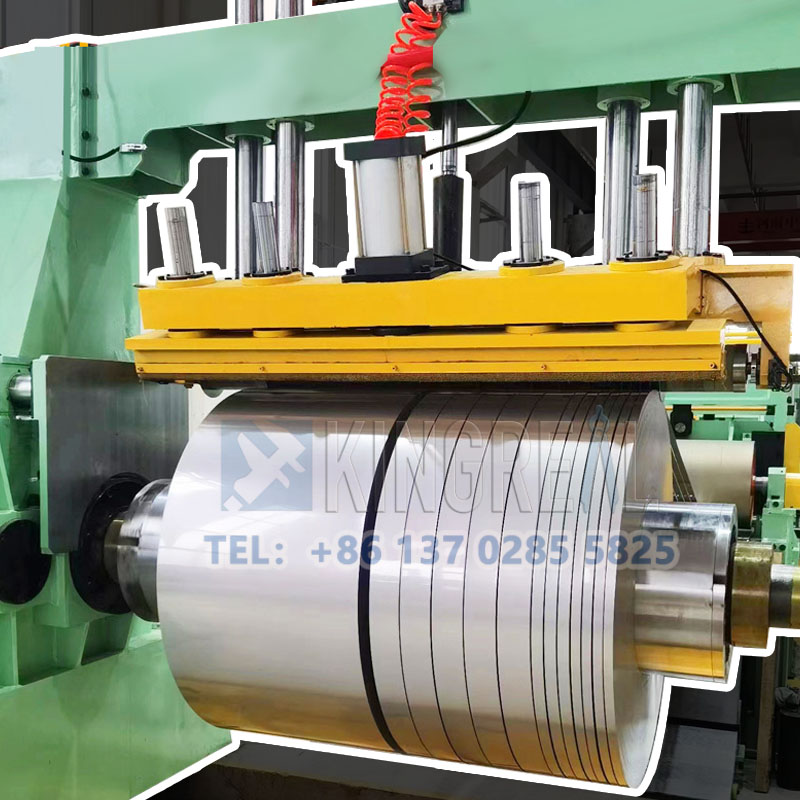

Description Of Metal Coil Slitting Line

Metal slitting line, also called metal coil slitting machine, is used to process different metal coils into small strips of specified widths with high-precision slitting process, and finally multiple narrower slit metal coils are obtained through the process of belt tension, which is widely used in many industries, such as automobile manufacturing industry and metal processing.

KINGREAL SLITTING metal slitting line can meet the demand of different materials (aluminum, stainless steel, galvanized steel, silicon steel, copper), different thicknesses (0.3-20MM), different widths (500-2000MM) and various customized production requirements. As a professional manufacturer of coil processing equipment, KINGREAL SLITTING is constantly improving its professionalism and breaking through design barriers to meet the development of all types of steel mill processing needs.

The processing flow of metal slitting machine usually includes unfolding large rolls of metal materials (such as steel coils, stainless steel coils, etc.) through the decoiler and feeding them into the slitting machine, utilizing the leveling machine to correct the waves, bends and other defects of the unfolded metal materials to make them flat, and then cutting the flat metal materials through the slitting machine longitudinally, slitting them into the narrow strips of the required widths, and the edges and corners generated during the cutting process are collected and disposed of through the waste treatment device. Collecting and processing. In the process of slitting and winding, the tension of the metal material is controlled by the tension device to ensure the leveling and winding quality of the coil, and finally the slit narrow strips are rewound into small rolls by the winding machine, which is convenient for subsequent storage and transportation.

Metal Coil Slitting Machine Standard Component List

No. | Name | Qty. |

1 | Material storage table | 1 pair |

2 | Feeding trolley | 1 set |

3 | Double cone Uncoiler + Recoiler | 1 set |

4 | 1# Bridge | 1 set |

5 | Guiding device | 1 set |

6 | Slitting machine | 1 set |

7 | Material transition device | 1 set |

8 | Integral edge trimmer | 1 set |

9 | 2#Bridge | 1 set |

10 | Tensioner | 1 set |

11 | Winding machine (with separating frame) | 1 set |

12 | Unloading trolley | 1 set |

13 | Hydraulic system | 2 sets |

14 | Pneumatic system | 1 set |

Technical Specification Of Metal Slitting Line

Material parameters:

No. | Name | Technical Parameters |

1 | Material | HR CR PO |

2 | Thickness | 0.3-4.0mm |

3 | Material width | 800-2000mm |

4 | Coil outer diameter | ≤Φ2000mm |

5 | Max weight of coil | 20T |

Main components parameter

No. | Name | Technical Parameters |

1 | Inner diameter | Φ508mm |

2 | Outer diameter | ≤Φ1800mm |

3 | Product Max capacity | Max:20T |

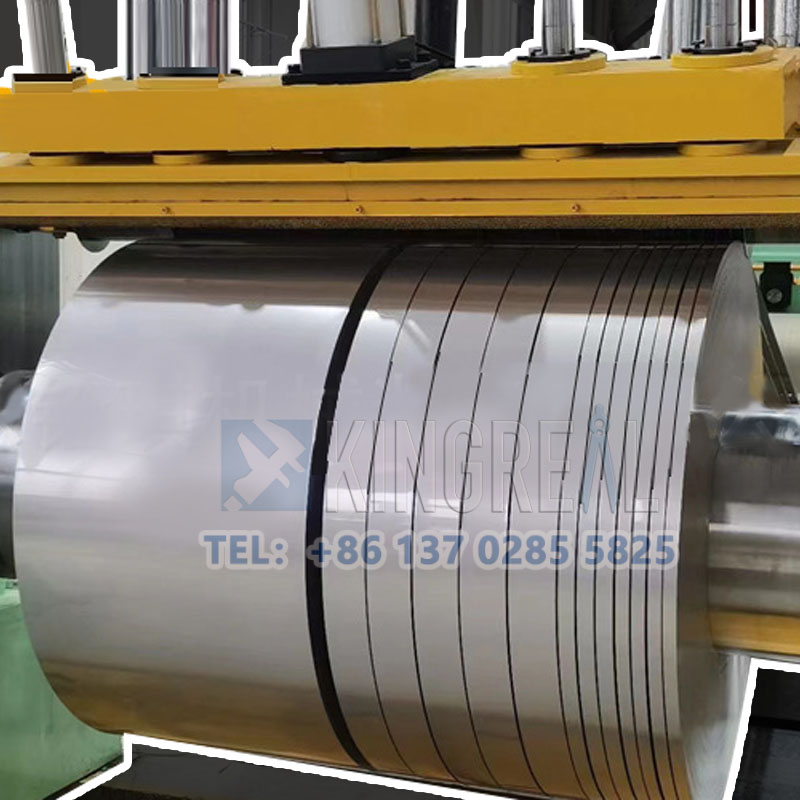

4 | Slit strips | 0.3-3.0mm thickness max 30 strips 3.0-4.0mm thickness max 15 strips |

5 | Min Strip width | 25mm |

6 | Slitting Speed | 0-120m/min(For 0.3~2.0mm thickness) |

7 | Yield strength of materials | 570Mpa |

8 | Equipment center height | 900mm |

Main Component Details:

1. Decoiler Trolley

Heavy frame welded by steel plate, oil pressure and motor control | |

Quantity | 1 set |

V-shaped surface | Nylon plate + steel plate welding |

Load-bearing | 15T |

Lifting stroke | 600mm |

Trolley power | motor |

Speed | 7m/min |

2. Hydraulic Decoiler

Load-bearing | 15T |

Steel coil inner diameter | Φ508mm |

Steel coil outer diameter | MAX: Φ1800mm |

Unwinding arc plate structure | Cantilever type, four-piece curved plate structure |

Expansion and contraction range of arc plate | Φ470mm-Φ508mm |

Curved plate | 45# cast steel (chrome-plated and polished surface) |

Unwind brake | 2 sets of disc brakes |

3. Main Slitting Machine

Slitting speed | 120m/min |

Tool shaft diameter | Φ160mm×1600mm |

Material | 42CrMo |

Cutter size | Φ280mm×Φ160mm×15mm(Outter diameter*inner diameter*thickness) |

Main motor power | AC75Kw |

4. Scrap collection device

composition | Composed of winding shaft, pressing shaft and transmission. Controlled by oil cylinder, convenient for unloading |

quantity | One left and one side feeder; can be used independently |

Rewinding scrap width | 2-10mm per side |

Winding speed | 0-120m/min |

5. Recoiler

Load-bearing | 15T |

Steel coil inner diameter | Φ508mm |

Spindle material | 42CrMo |

Reel flap arc plate | After quenching and tempering treatment of 45# steel, the surface is plated with hard chrome |

Clamping jaw | Cylinder drive expansion and contraction |

Advantage Of Metal Coil Slitting Line

1.Meet the processing needs of a wide range of raw materials . Metal slitting machines are capable of processing a wide range of materials, including stainless steel, carbon steel, aluminum, copper and other various metal coils. Their high adaptability allows them to be used in a wide range of applications across multiple industries, such as construction, automotive, aerospace, electronics, and more.

2. Supporting highly customized design. The slitting machine can be customized to meet specific customer needs, from tool configuration to tension control system can be flexibly adjusted to meet the requirements of different material properties and specific processing standards.

3. Efficient production and precise cutting. Adopting advanced automation and control technology, the metal slitting machine is able to realize efficient production process, reduce downtime and increase output. At the same time, the high-precision shearing system ensures cutting accuracy and edge quality.

4. High degree of automation. Modern metal slitting machines are equipped with automated tool changing, tension adjustment and scrap handling systems, these features reduce manual intervention, usually only 1-2 workers are needed to complete the production operation, which improves production efficiency and safety.

5. Stable and reliable performance . The robust design of the equipment is able to withstand intense operating environments, ensuring stable operation for long periods of time. High-quality tools and components reduce wear and maintenance requirements, extending the life of the machine.

6. Easy to operate and maintain. Equipped with user-friendly human-machine interface and intelligent control system, it makes operation and maintenance easy and intuitive. Training time and maintenance costs are significantly reduced.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil