Description Of Copper Strip Coil Slitting Line

KINGREAL SLITTING Copper Strip Coil Slitting Line is a superior machine designed to accurately cut metal coils into narrow strips, which provides significant economic benefits in the metal coil slitting industry. Not only does this machine have an efficient cutting capacity, but it also offers significant operating cost reductions and benefits to the organization.

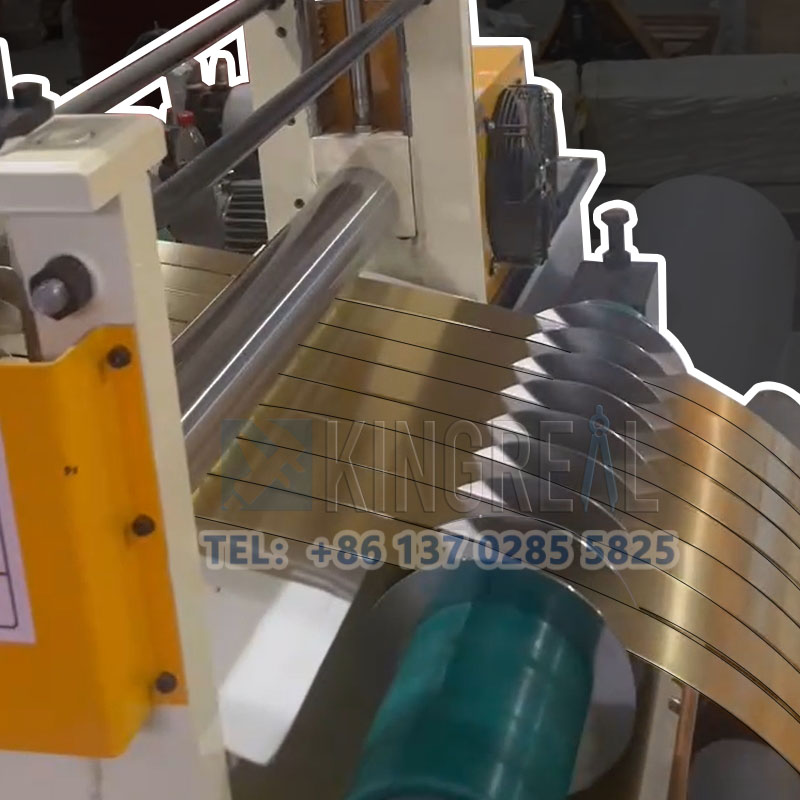

The KINGREAL Copper Coil Slitter utilizes advanced cutting technology to easily cut wide coils into precise narrow strips. Its high-precision cutting knives and stable operation mechanism ensure that each cut copper strip has a flat edge and consistent width. This precision not only improves product quality, but also reduces material waste and further enhances production efficiency.

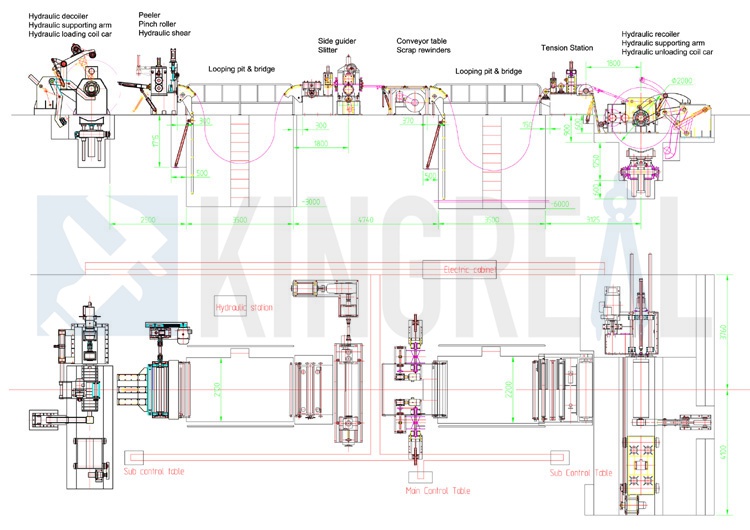

The copper coil slitting line is a continuous operation slitting line whose main processes include unwinding, slitting and winding. First, the wide coil is unrolled by the decoiler; next, the slitter cuts the coil into narrow strips of a specific width; finally, the cut narrow strips are rewound into a number of coils by the winder for subsequent processing and transportation.

Working Process of Copper Coil Slitting Line

Coil loading Trolley → Hydraulic Decoiler → Pinch Straightener → Pit Loop → Coil Side Guider → Guide Align / Disc Slitting → Side Scrap Collector → Pit Loops → Tensioner → Rewinder Machine → Coils Unloading → Finished Products

Specifications of Copper Coil Slitter

Processing material | Cold rolled copper coil |

Maximum tensile strength | Consider ultimate strength 80kg/mm2 |

Maximum yield strength | 60kg/mm2 |

Plate thickness | 0.1mm-1.2mm |

Board pair | 310mm-680mm |

Coil outer diameter | Φ1600mm |

Inner diameter of coil | Φ500mm |

Coil weight | 10000kg |

Rewinding outer diameter | Φ1500mm |

Rewinding inner diameter | Φ250, Φ300, Φ400, Φ500 |

Winder load | Maximum 10000kg |

Features of Copper Slitting Line Machine

1. High-quality precision

The guide device of the brass coil slitting machine consists primarily of left and right sliders, worm gears, and worms. The implementation of the slider structure significantly reduces the gap within the guide mechanism, ensuring that the axial movement of the main shaft remains under 0.1mm, and the radial gap is less than 0.03mm. This enhancement improves the stability of the spindle, thereby guaranteeing high shearing accuracy.

2. Easy operation

The brass strip slitting machine is designed for easy operation. The sliding seat can be effortlessly moved along the base using a motor-driven sliding rail, making it convenient to replace the cutter head, cutter pad, and spacers. The upper and lower cutter shafts are supported by bushings on both the movable and fixed supports of the frame. The cutting depth of the blade can be precisely adjusted by altering the distance between the cutter shafts through the worm gear and worm mechanism, ensuring optimal performance.

3. Long Service Life

The base of the brass strip slitting machine primarily consists of a fixed base, a movable base, and a motor bracket. These components are welded using high-quality steel plates. After welding, the base undergoes an aging treatment, which ensures excellent rigidity and prevents deformation. This robust construction contributes significantly to the long service life of the machine, ensuring it remains reliable and efficient over extended periods of use.

Application of Copper Coil

- Electronic communications

- Household appliances

- Transportation

- Energy storage

- Electricity

FAQ : About Coil Slitting Machine

1. What are the common coil slitting machine classifications?

·Different Thickness Slitting Line

Light Gauge Steel Coil Slitting Line

Medium Gauge Metal Slitting Machine

Heavy Duty Coil Slitting Lines

·Different Materials Slitting Line

Stainless Steel Slitting Lines

Silicon Coil Slitting Lines

·Different Configurations Coil Slitting Machine

Dual Slitter Head Coil Slitting Line

Belt Tension Coil Slitting Machine

2. How do I get a quote for coil slitting line?

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you

·Coil Material

·Coil Thickness

·Coil Width

·Coil Weight

·Slit Width

·Slit Speed

3. What are the optional configurations for the slitter line?

·Decoiler Machine

KINGREAL SLITTING unwind systems offer a wide range of options, including hydraulic unwinds, auxiliary support arms, loading trolleys, etc., to support large rolls and fully automate the unwind process.

·Dual Slitter Head

KINGREAL SLITTING offers the option of dual slitter head for the slitting head, an important part of the coil slitting line, to help customers slit different sized coils in a single line through a quick change of knife holders. By adding guide rails and other devices on the slitting machine line, the size to be slit can be adjusted in advance on the dual slitter head, which can meet the needs of different sizes of slitting.

·Belt Tension Station

During the slitting process, the belt is responsible for the even and smooth transfer of the web material to the cutting position. The proper belt tension ensures the stability of the material during the transfer process and avoids slippage or deflection of the material during the transfer process.

Proper tension prevents material damage during transfer. Too much tension may deform or break the material, while too little tension may cause the material to kink or fold during transfer. Correct belt tension reduces wear between the belt and the drive, extending the life of the equipment

·Auto Package Lin For The Slit Coil

An automated metal coil baling line is a machine for automated baling of metal coils (e.g., aluminum, steel, etc.). It cuts, coils and bales metal coils into standardized packages on demand for transportation and storage by means of robotic arms, conveyor belts and other automated components.

KINGREAL SLITTING supports the combined design of an automated metal coil baling line and a slitter line to realize fully automated slitting-rewinding-unwinding-baling production requirements for large-scale steel processing plants.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil