Video About Fully Automatic Metal Slitting Machine

Description Of Full Auto Metal Slitting Machine

KINGREAL SLITTING Automatic Metal Slitting Machine is an efficient equipment for slitting metal coil, which completes the whole process from loading to coil packing through automated process.

Automatic metal slitting machine, mainly used for metal coil slitting, such as cold and hot rolled strip, stainless steel, copper, aluminum, galvanized, etc.. The metal slitting processing line is widely used in metal sheet processing industry such as automobiles, agricultural vehicles, containers, home appliances, building materials, etc.

KINGREAL STEEL has equipped its fully automated metal slitting line with the following designs and features to increase the efficiency of slitting:

1. Automatic loading and unloading system.

The coil unwind and rewind system for slitting is equipped with hydraulic tension unwind, loading and unloading carts and auxiliary support arms. It caters to the process of loading and unloading of coils of different sizes and roll weights.

2. Dual knife holder slitting design. By debugging the spacing and spacer of different knife holders, the knife holders can be changed automatically through the guide rail to realize the production process of slitting different sizes in one production line.

3. Fully automatic packing device. After the automatic metal slitting machine finishes the final slitting and winding process, there will be a fully automatic packing device to carry out the coil unloading, winding and packing process.

In order to increase the production speed of the metal slitting machine, it can be as high as 200M/Min.

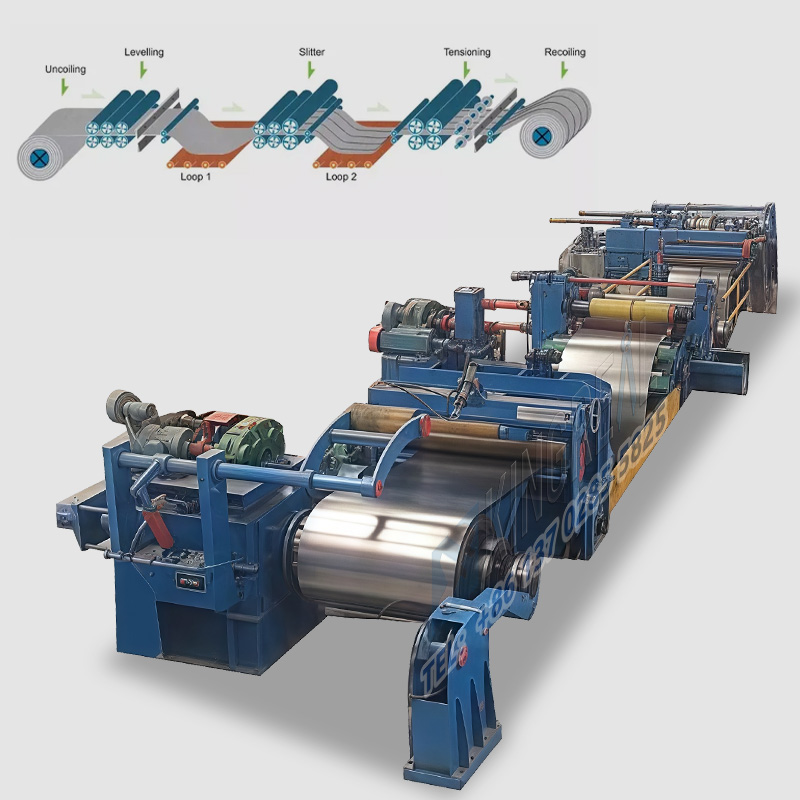

Working Process of Metal Slitting Line

Upload material -- Decoiler -- Clip feed leveler/shearer -- First Loop bridge -- Guide and Slitting -- Scrap collection -- Second Loop bridge -- Tension machine -- Uncoiler slitted coil -- Unload Coils -- Auto Package

Metal Slitting Line Components List

No. | Name | Quantity |

1 | Material coil table | 1 unit |

2 | Coil Load Trolley | 1 unit |

3 | Hydraulic decoiler | 1 set |

4 | Material feeder, pinch roller and hydraulic shearing | 1 set |

5 | Loop bridge | 1 set |

6 | Manual side gudie and pinch feeding | 1 set |

7 | Main slitting machine | 1 unit |

8 | Splicing rack and trimmer with scrap colletcor | 1 set |

9 | Loop bridge | 1 set |

10 | Seperator, tension station | 1 set |

11 | Separators, uncoiler and punshing material device | 1 set |

12 | Hydraulic support | 1 set |

13 | Unloading trolley | 1 set |

14 | Hydraulic system | 1 set |

15 | Eletronic control system | 1 set |

16 | Lubrication system | 1 set |

17 | Pneumatic system | 1 set |

18 | Spare parts | 1 set |

Metal Slitting Machine Component Details:

◇Unwinder: 508 and 610 mm inner diameter of steel coils, constant counter tension by AC servo motor, automatic coil loading and center positioning assistance system.

◇Roughing machine: electronic data display, electric adjustment, reduce the curvature of the plate.

◇Front buffer pit: Platform type lift, convenient for plate passing, and can adjust the discharge speed according to the characteristics of different plates.

◇Slitting knife block set: exchangeable multi-set slitting knife block set, which can reduce the downtime when changing knives, lower knife shaft lift type knife feed adjustment, effectively reduce the impact of screw tooth gap on knife feed accuracy.

◇Side material winder: vertical side material winding, side material winding and recycling are more convenient, and with conveyor can make the coil material lifting more convenient.

◇Back buffer pit: The swinging platform can make the pass board convenient and provide enough buffer space.

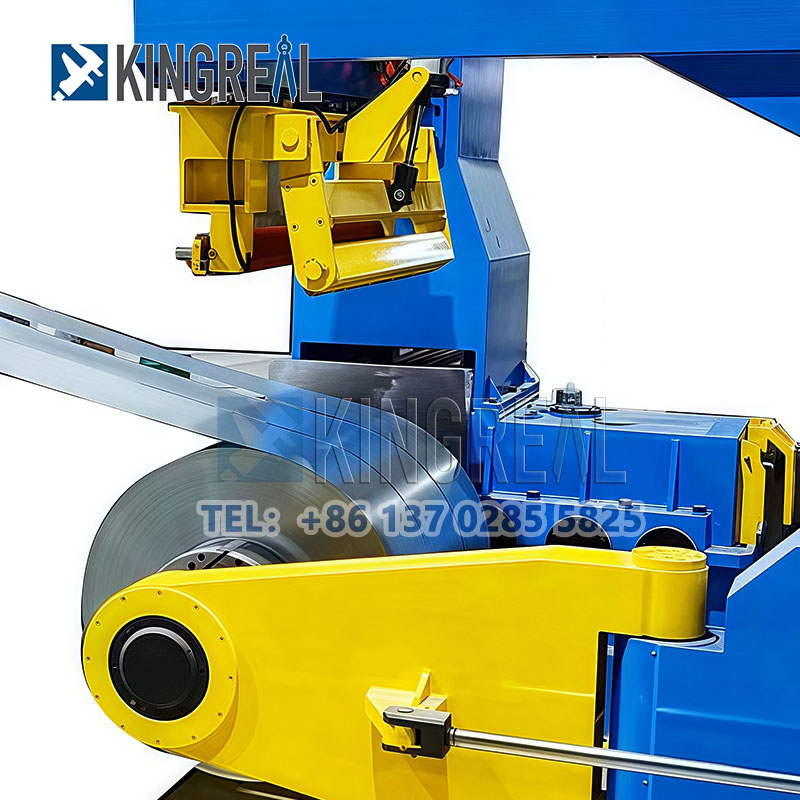

◇Belt tension: A belt tension is used to achieve high stability of winding, using a belt or wool felt.

◇Adjustable rutting pulley: adjustable height design, can adjust the height according to the characteristics of the material to achieve the best winding angle.

◇Winding machine: five seamless curved leaf plate slant pins with chrome plating on the outside diameter of the rise and shrink to reduce damage to the inner ring of the coil, and AC servo motor to achieve constant tension winding function.

Types of metal slitting Machine offered by KINGREAL SLITTING

1. Based on Metal Slitting Thickness

Light Gauge Metal Slitting Machine: This type of steel slitting line is designed to handle materials with a processing thickness ranging from 0.3mm to 3.0mm. It is ideal for applications requiring precision cutting of thinner metal sheets, such as in the electronics and packaging industries.

Heavy Gauge Metal Slitting Machine: In contrast, thick plate steel slitting lines process materials with a thickness of 6mm to 20mm. These machines are suited for heavy-duty applications where robust and thicker metal strips are needed, such as in construction and automotive manufacturing.

2. Based on the Metal Coil Material

◆Copper Strip Slitting Line: Specifically designed for processing copper coils, these slitting lines ensure precise and clean cuts, maintaining the high conductivity and quality of copper.

◆Stainless Steel Slitting Line: These machines are optimized to handle stainless steel coils, ensuring that the material's corrosion-resistant properties are preserved during the slitting process. They are widely used in industries such as kitchenware, construction, and medical devices.

◆Cold Plate Slitting Line: Ideal for processing cold-rolled steel, these lines produce smooth and precise cuts, making them perfect for applications requiring high surface quality, such as automotive panels and appliances.

◆Silicon Steel Slitting Line: Designed for processing silicon steel, which is commonly used in the manufacturing of electrical transformers and motors, these slitting lines ensure minimal loss and high efficiency.

◆Tinplate Slitting Line: These lines specialize in cutting tinplate, which is used extensively in the packaging industry, especially for food and beverage containers.

3. Based on the Degree of Automation

◆Automatic Slitting Line: Fully automated slitting lines incorporate advanced PLC control systems, which allow for precise input of order amounts, cutting specifications, and operational speeds. These lines reduce manual intervention, increase efficiency, and ensure consistent quality, making them ideal for large-scale production environments.

◆Semi-Automatic Slitting Line: These lines offer a blend of manual and automated processes. They are designed for operations that require some degree of human intervention, providing flexibility and control while still benefiting from some automation features.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil