Description of Coil Packing Machine

KINGREAL vertical coil wrapping machine is an automated metal coil packaging system. This coil banding line is mainly used for coil picking, automatic packaging, stacking of slitting steel coils, and uses LLDPE stretch film and compound paper as the main packaging materials.

It is suitable for the packaging needs of different metal coils such as steel coils, stainless steel coils, aluminum coils, and copper coils. KINGREAL vertical coil packing machine can ensure that metal coils are well packaged and neatly stacked and have the characteristics of protecting the surface of metal coils from scratches and oxidation.

Workflow Of Coil Banding Line

feeding - wrapping - turning - weighing - stacking and unloading

Parameters

◇Outer diameter: 800mm-1500mm

◇Inner diameter: 508-610mm

◇Width: 50mm-400mm

◇Weight: ≤15T

◇Materials: LLDPE stretch film / compound paper

◇Wrapping overlap: 20%-70% adjustable

◇Wrapping material size: Width 100mm, OD 500mm, ID 50mm

Main Components Of Coil Banding Line

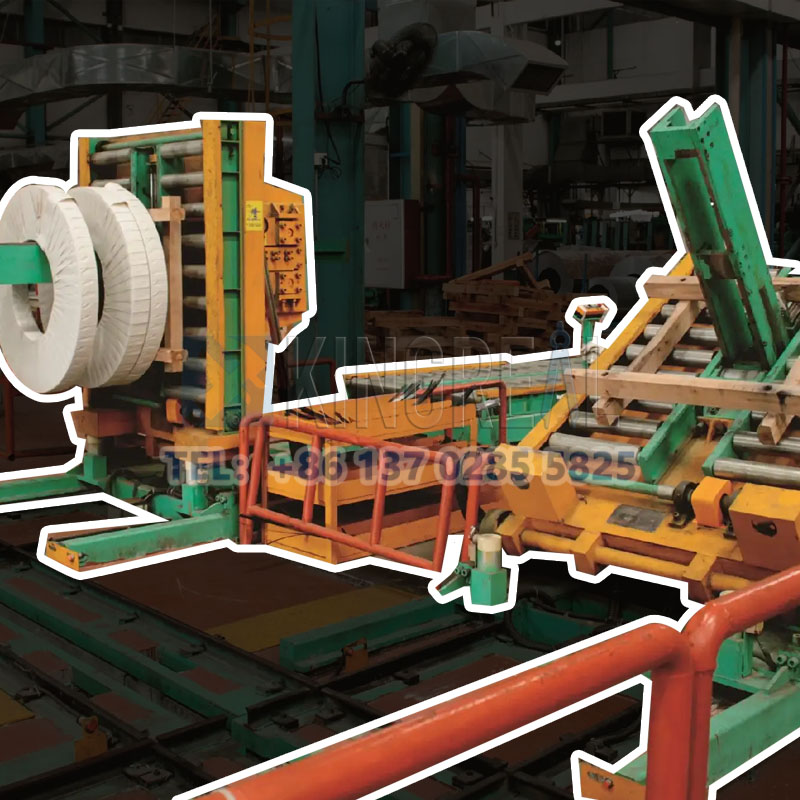

① Mobile feeding trolley

Automatically delivering metal coils to wrapping not only saves manpower, but also can quickly and efficiently replenish the metal coils required by the coil vertical packaging line, avoiding production stagnation or delays caused by shortage of metal coils.

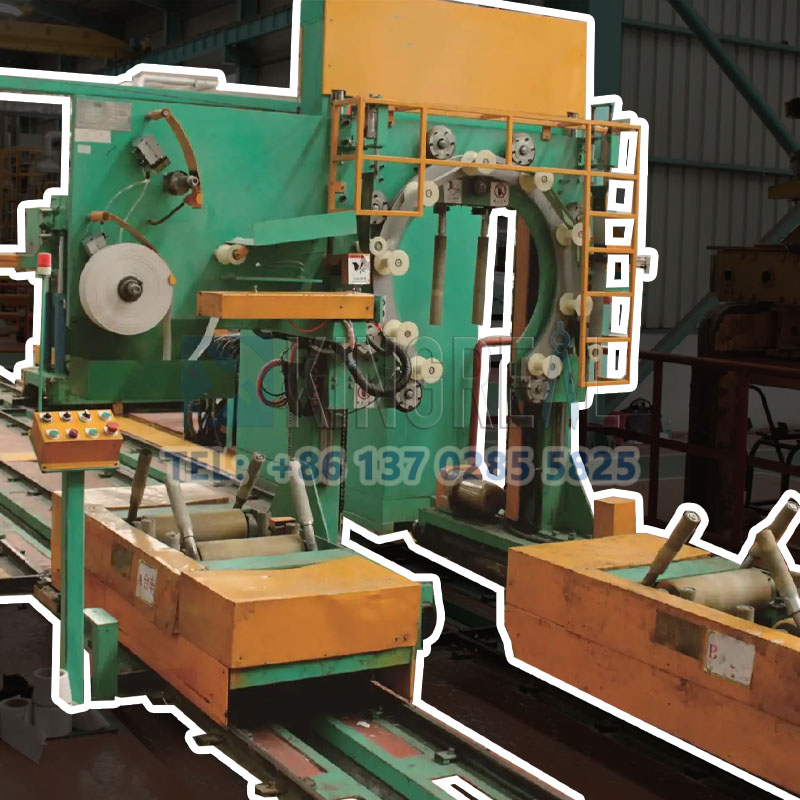

② Automatic wrapping packaging machine

KINGREAL automatic coil vertical packaging line is equipped with double storage boxes. The design of the double storage box allows one storage box to be used while the other storage box is used as a spare or replacement. When one storage belt is used up, it can immediately switch to another storage belt for packaging, avoiding downtime due to film or belt replacement, thereby greatly reducing downtime in the production process.

③ Stacking flip machine

Mainly used to flip or invert the stacked coil packaging. It also adjusts the direction, position or posture of the packaging coil according to the actual needs of the customer, preparing for subsequent boxing, handling and loading.

④ Powered conveyor line

The powered conveyor line with weighing equipped with KINGREAL vertical coil packing line can weigh the packaging coils in real time while they are transported along the conveyor belt, avoiding the error of manual weighing and improving the weighing accuracy.

And the design of the weighing screen with dual display screen allows the operator to monitor the real-time weight and historical data at the same time, which is convenient for quick judgment and adjustment.

⑤ Rear discharge channel

The rear discharge channel of KINGREAL vertical coil wrapping machine is adjustable. According to the actual production needs of customers, the channel can be opened or closed by using a touch screen or mechanical buttons. When the channel is closed, the packaged coils will be stacked to the flip machine. When the channel is open, the material can be discharged directly without going through other steps.

Advantages of Coil Packing Machine

①Using a unique tension adjustment mechanism. The wrapping overlap rate of the KINGREAL coil banding line is adjustable from 20% to 70%, and customers can adjust the tightness and overlap of the packaging as needed. It is suitable for various occasions from economical packaging to high-protection packaging. At the same time, when switching between different specifications of items, the overlap rate can be adjusted quickly, without the need to frequently change packaging materials or shut down the equipment for debugging, saving time and improving efficiency.

② Compatible with two different packaging materials. KINGREAL Vertical packaging strapping line is convenient for customers who have different requirements for metal coil packaging materials, and the machine can be packaged with two different packaging materials at the same time.

③The packaging time can be set on the control panel to achieve automatic shutdown.

The operator only needs to simply set the required packaging time or cycle parameters on the control panel before starting to wrap the metal coil, and the KINGREAL coil vertical packaging line can automatically run according to the settings and shut down after completion.

④Automatic cutting

The length of the wound metal coil can be entered in advance on the program control panel, and there is no need to manually cut and knot the coil packaging, achieving maximum automation.

Why Choose A Coil Vertical Packaging Line?

① Save space

The design of the vertical coil wrapping machine allows the machine to occupy less ground space. Compared with the horizontal packaging line, the vertical coil packing line does not require a long horizontal conveyor belt or a large platform to support the metal coils, so it is more suitable for installation in places with limited plant space.

② Improve packaging stability

During the winding process of the vertical coil wrapping machine, the metal coils are usually in a vertical state. This design can reduce the rolling and deviation of the coils during transportation and storage, thereby avoiding the tilting or instability that may occur during the packaging process, and ensuring the tightness and stability of the bundle.

③ Strong compatibility

The coil packing machine can adjust the machine settings according to the coils of different diameters and widths to adapt to metal coils of different specifications.

④ Fast packaging speed

The vertical coil packing line adopts a vertical arrangement. During the winding process of the coils, the machine has a smaller operating range and higher work efficiency.

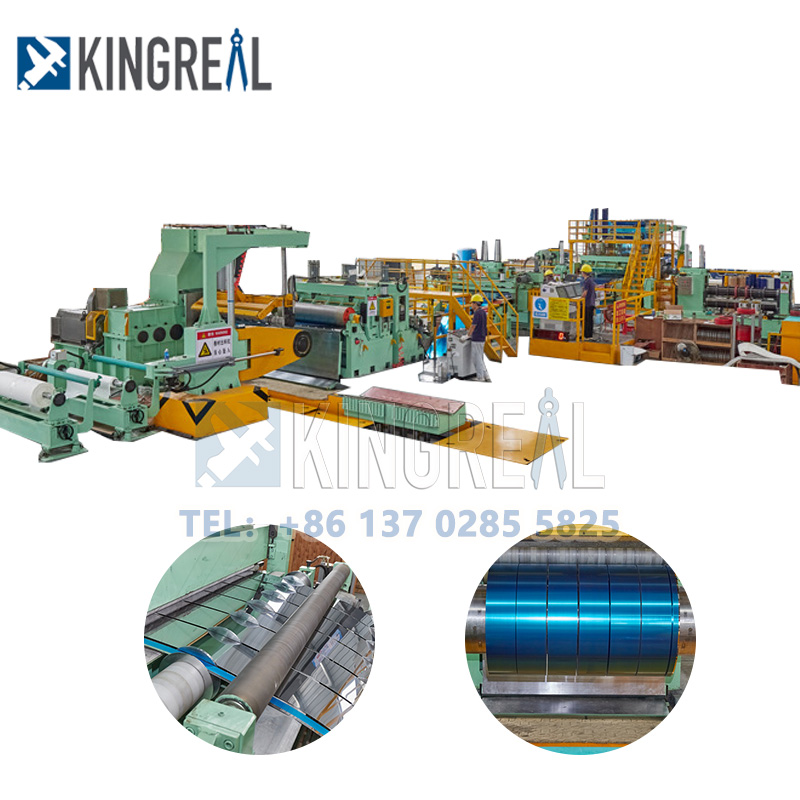

Used With Coil Slitting Machine

The combination of coil packing machine and coil slitting machine creates an efficient and automated production line from processing to packaging. KINGREAL coil slitting machine is responsible for precise slitting, and coil packing machine is responsible for protecting packaging and subsequent processing. After the metal raw materials are processed into narrow strips by the coil slitting machine, they can directly enter the coil banding line through the conveying equipment to wrap the coils, so that the metal coils are relatively sealed to prevent damage during transportation and storage.

The combination of the two can significantly improve production efficiency, reduce manual operations, optimize packaging quality, and adapt to diverse production needs, especially in the field of metal processing that requires high efficiency and high standards. It has important value.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil