Video About Silicon Coil Slitting Line?

Description Of Silicon Coil Slitting Line

KINGREAL COIL SLITTING silicon coil slitting line is a production and processing machine that slits rolls of silicon steel strip into a certain width and then rolls them into coils under a certain coiling tension with high precision. Silicon steel slitting lines produce silicon steel slitting coils that are widely used in the transformer industry for the production of transformer cores, motor cores and reactors and capacitors. This requires a high degree of precision in the processing of silicon steel slitting lines.

Silicon steel coil slitting machine produced by KINGREAL SLITTING can ensured without causing any harm to the fine materials used, such as silicon metal sheets with dimensions from 0.18 to 0.5 mm. Cutting, slotting and stacking are a complex series of silicon coil slitting machine production processes. In addition to this, the process requires fast start-stop action and a safe process. The maximum width of silicon steel material that can be processed is 1250mm, and the minimum width of slit strips is 40mm, supporting customized design and production.

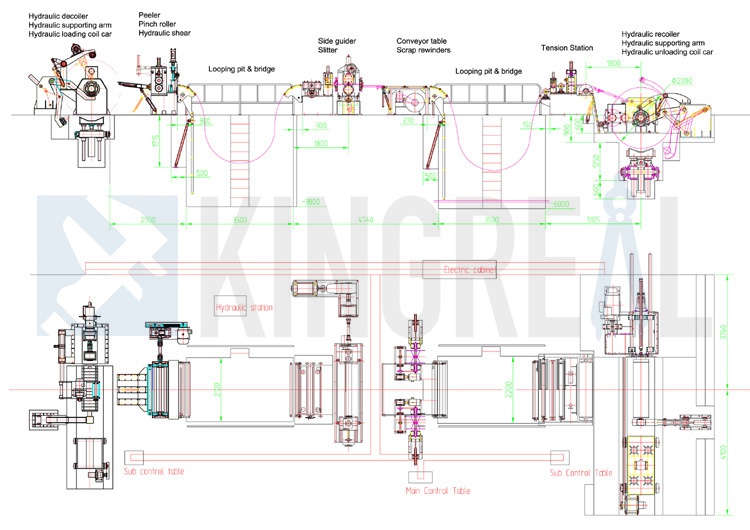

Working Process of Steel Coil Slitting Line

Upload material -- Decoiler -- Clip feed leveler/shearer -- First Loop bridge -- Guide and Slitting -- Scrap collection -- Second Loop bridge -- Tension machine -- Uncoiler slitted coil -- Unload Coils

Technical Specification Of Silicon Coil Slitting Machine

Material | Hot rolled steel |

Steel Thickness | 4~10mm |

Steel Width | 800~2500mm |

Coil I.D | 500~800mm |

Steel Weight | 35T |

35T | HRC58°—60° |

Blade Specification | φ300×φ480×30 |

Slit Quantity | 10pcs for 4-6mm, 6-8pcs for7-8mm,5pcs for 8-10mm |

Slitting Width Precision | ±0.10mm |

Slit Width(Min) | 150mm |

Scrap Winder width | ≥1.5 times of thick |

Recoiler I. | φ610mm |

Main Component Functions

·Decoiler System

1. The loading table can be pre-packed with multiple rolls to improve the working efficiency.

2. This slitting line uncoiling unit adopts a hydraulic collapsible roller, no harm to the bottom layer of material. It can be stretch uncoiling or manual unloading, effectively preventing the material from deflection and scratching.

Guide Device

The guide device plays a crucial role in the slitting machine production line, particularly at the initial stage of handling coils. Its main functions and significance are as follows:

·Pinch Rollers

1. Pinch rollers are key components in the slitting machine, used for feeding the sheet to the straightener. The pinch rollers feed the sheet to the straightener for further processing. The lower roller is fixed, while the upper roller is pneumatically controlled to move up and down, with both rollers actively driven to ensure smooth feeding.

2. By precisely controlling the distance and pressure between the upper and lower rollers, the pinch rollers ensure that the sheet is fed smoothly and without deviation, enhancing feeding efficiency and precision.

3. During the feeding process, the pinch rollers apply uniform pressure to the sheet, aiding in its preliminary flattening.This process lays the foundation for the subsequent operation of the straightener, ensuring the sheet has better initial flatness when entering the straightener, thereby improving the straightening effect and the final product quality.

·Guiding and Straightening

1. During the initial threading of the coil, the guide device contacts the leading edge of the sheet, straightening any bent parts to ensure smooth entry into subsequent processing stages.

2. This process guarantees the flatness and smooth passage of the sheet head before entering the pinch rollers, avoiding material damage and jamming, and thus enhancing the continuity and efficiency of production.

3. The guide device ensures the flatness of the sheet head through its straightening action. A flat sheet head can better cooperate with subsequent equipment, improving overall processing quality, reducing scrap rates, and ensuring consistent product quality.

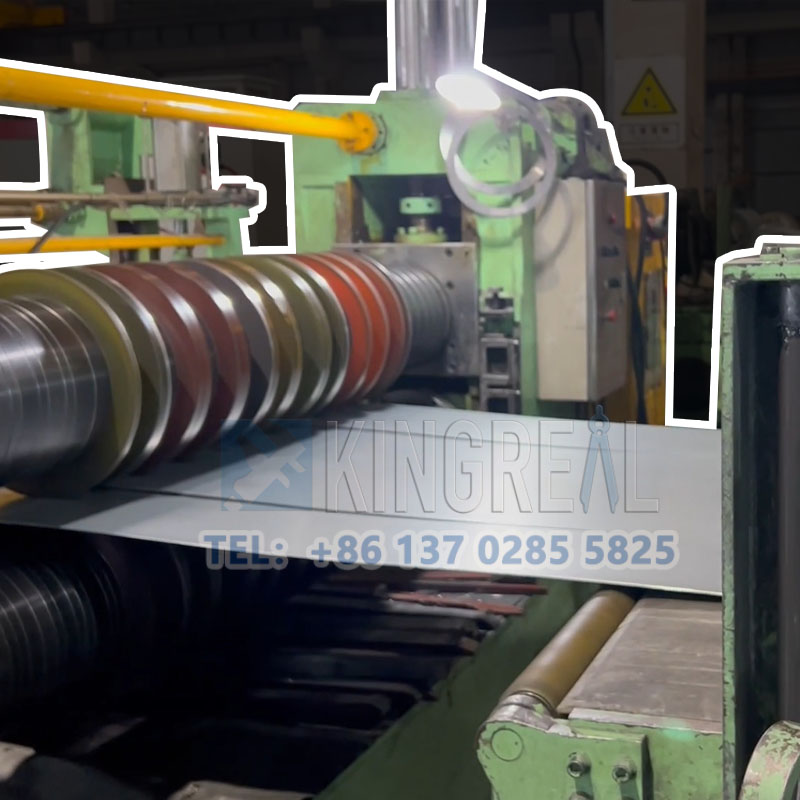

·Main Slitting Machine

1. The slitting head mandrel is fixed in the eccentric sleeve. If the blade is just polished, the slitting angle remains the same.

2. The slitting line has two slitting heads. While one is running online, the other can be set up for equipment, which can greatly eliminate production downtime.

3. Hydraulic lock nut is used for higher accuracy of blade positioning.

·Tension Station

1. The tension unit is equipped with two pre-separation devices. The separation axis can be removed laterally for faster spacer switching. 2.

2. With frictional tension table. Adjustable tension can be provided by hydraulic or pneumatic. 3.

3. Our slitting lines can also be equipped with a roller type tightener, which is suitable for materials with coated surfaces, as it does not damage the coated surface.

·Rewinding Machine

1. The slitting line can be equipped with a seamless hydraulic retractable winder, which does not damage the material substrate.

2. The clamping device has stress-reducing characteristics. For different thicknesses of the sheet, the roundness of the reel remains the same.

3. Coiling is firm, dense and neat.

Feature Of Silicon Steel Slitting Line

1. Silicon steel slitting machine has highly accurate cutting ability to cut silicon steel coil into uniform and smooth narrow strips. In the manufacture of transformer core, the precise silicon steel strip can ensure the stacking density of the core.

2. Silicon steel slitting machine is equipped with advanced automation control system and servo drive technology to achieve high-precision tension control and synchronized operation, which ensures consistency and accuracy of each slitting process.

3. Adopting high-quality alloy steel knives and precision cutting mechanism to ensure neat and burr-free cuts and smooth edges, which reduces the eddy current loss of the transformer core.

4. With precise tension control device, it can maintain the stability and uniform tension of the coil during the cutting process.

5. Silicon steel slitting machine adopts heavy-duty structure design, with high rigidity and stability, able to cope with long time, high intensity working environment, to meet the needs of high precision production of large quantities.

Please Confirm You Produce Need,And We Will Prepare The Quote For You

1. Coil Material

2. Coil Thickness/width/weight

3. Slit width

4. Slitting Speed

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil