Description Of Coil Strapping Machine

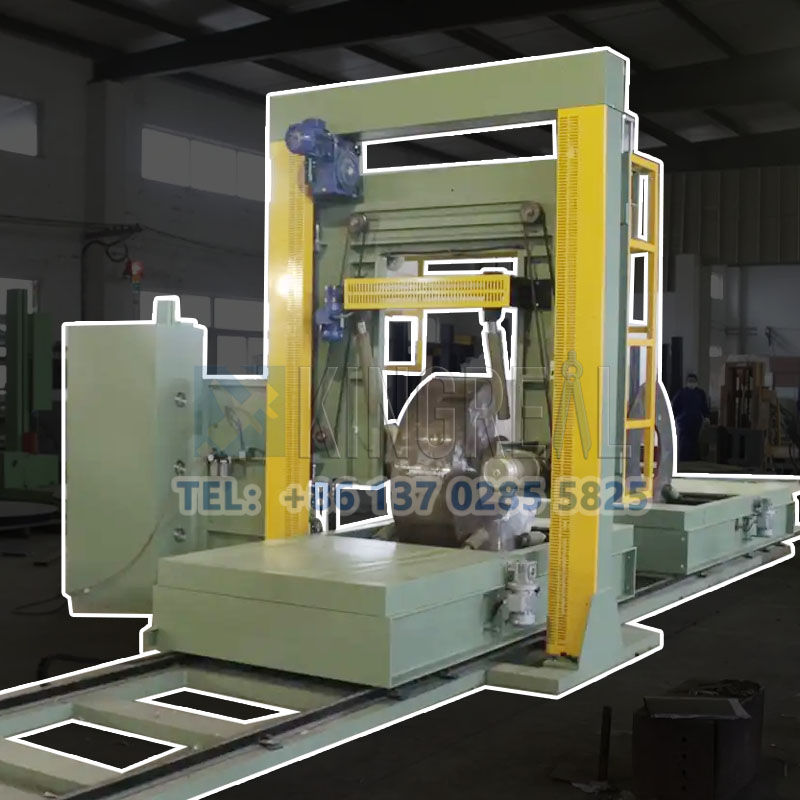

KINGREAL SLITTING coil wrapping machine wraps the strapping tape tightly around the outside of the metal coil in an automated way to form a tight packaging layer. It is mainly used in the production, storage and transportation of metal coils to ensure that the metal coils will not be damaged or scattered due to improper transportation or stacking. KINGREAL SLITTING metal coil wrapper has a fast speed for strapping metal coils, and can complete the wrapping of a roll of metal coils in 10-15 seconds. KINGREAL SLITTING coil banding line is efficient, accurate and stable, which can greatly improve packaging efficiency and reduce manual intervention.

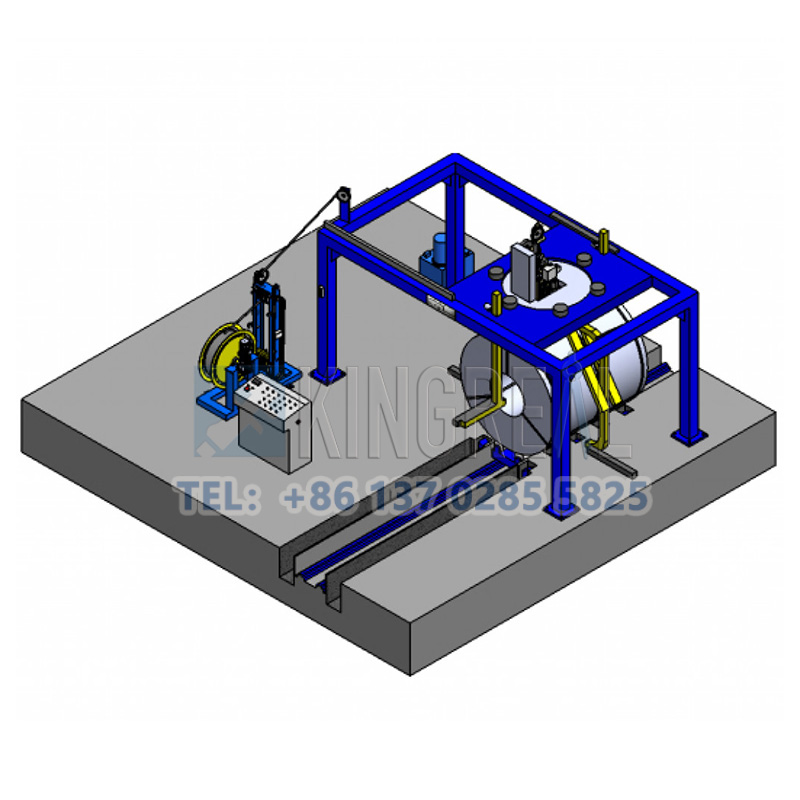

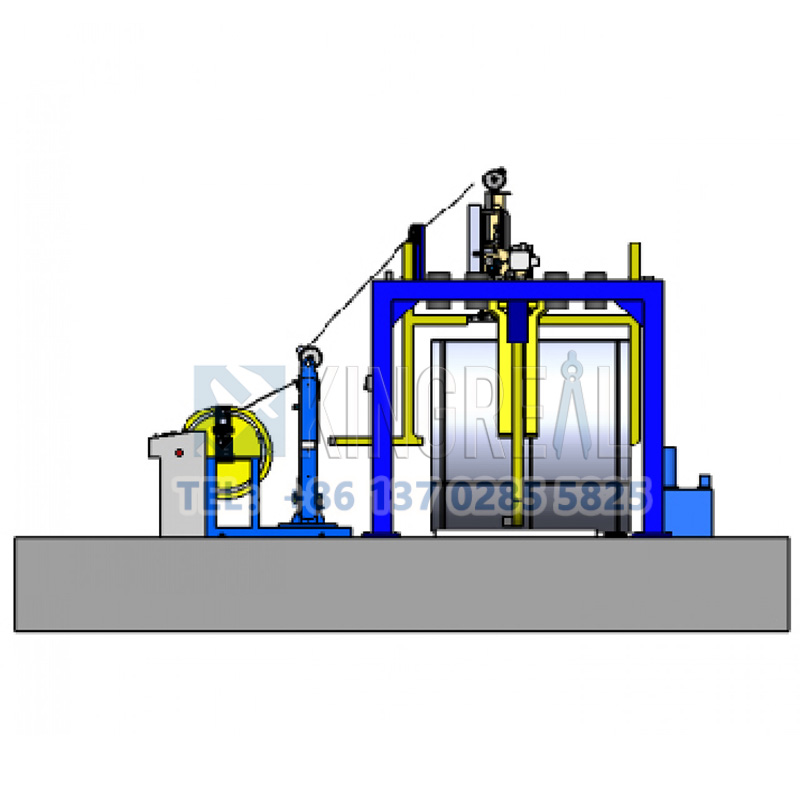

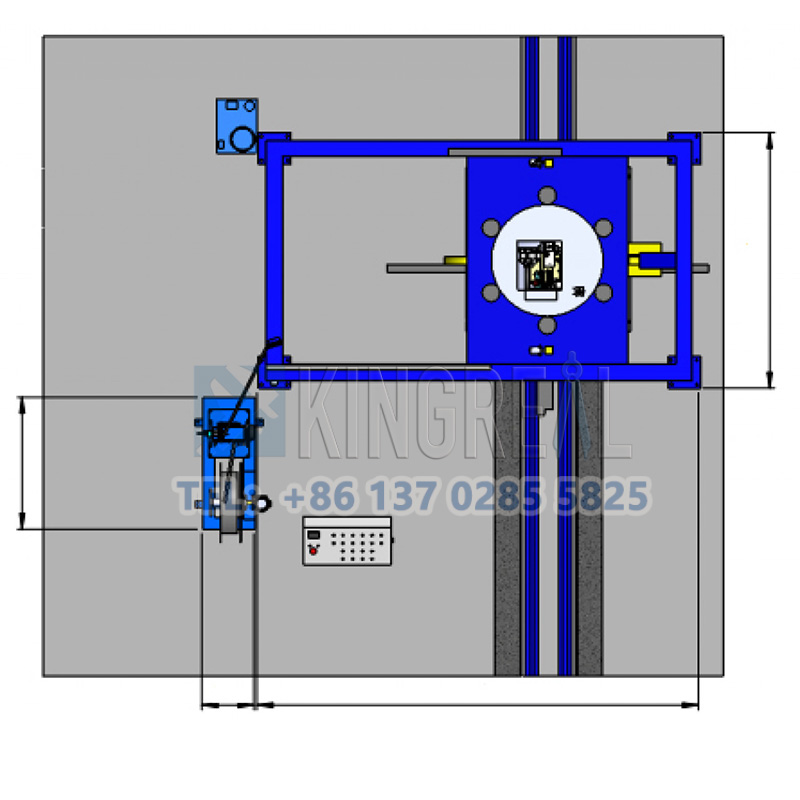

The coil banding line is mainly composed of wrapping machine, material transport trolley, control console, guardrail and other components. This coil strapping machine can perform radial bundling when the metal coil is in a vertical or horizontal position, and can bundle metal coils of different widths. In the metal coil wrapping bundling process, when the metal coil needs to be bundled, the metal coil will be transferred to each bundling position. During the process of winding metal coils, the metal coil wrapper will not damage the metal coils to be bundled because their contact area is protected by HDPE material.

Production process of coil packing machine

Feeding--wrapping--cutting tape & fixing--discharging

Parameters of coil packing machine

Product: Slit Coils

Outer diameter: 800mm-1500mm

Inner diameter: 508-610mm

Width: 50mm-400mm

Weight: ≤15T

Applicable packaging materials: woven tape, wire-reinforced crepe paper

Winding overlap rate: 20%-70% adjustable

Packaging material specifications: width 100mm, outer diameter 500mm, inner diameter 50mm

Advantages of coil strapping machine

①Replace manual handling and avoid work injuries. The coil wrapping machine

replaces traditional manual operation through automated handling and packaging functions, avoiding the physical burden and risk of work injuries caused by workers carrying heavy objects for a long time. Especially when handling large or heavy metal coils, the use of the machine greatly improves the safety of operation and can ensure production efficiency.

②Easy to operate. The operating interface of the KINGREAL coil packing machine’s system is intuitive and concise. This coil banding line is equipped with an advanced intelligent control system. Different parameter settings, such as bundling tension and number of bundling, can be adjusted through the touch screen. All operations are clear at a glance.

③ Customized solutions. KINGREAL can design according to customers' special requirements for packaging specifications of different metal coils and provide customers with customized coil packing machine solutions.

④ Fully automated system. KINGREAL metal coil wrapper adopts fully automated operation. From coil conveying, wrapping, fixing to cutting, each link is automatically completed by the system. It greatly improves the overall efficiency of the production line.

⑤ High-speed. KINGREAL coil strapping machine has a very high bundling speed, which is faster and more efficient than manual bundling. In addition to improving production efficiency, it can also meet the production needs of large-scale metal coil winding packaging.

⑥ Improve packaging precision.

Compared with manual winding, automated winding not only improves work efficiency, but also ensures the consistency and accuracy of the packaging process.

Used with coil slitting machine

KINGREAL SLITTING coil banding line and coil slitting machine can be used together to achieve automated production to the greatest extent. After the coil slitting line completes the segmentation of the metal sheets, the metal coil wrapper will immediately start packaging, reducing the intermediate waiting or manual handling links and ensuring the continuity and rapid response of the production process.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil