Video About Mini Metal Coil Slitting Machine

Description Of Mini Metal Coil Slitting Machine

Metal Slitter are used in a wide range of applications in the web processing industry to split a web into multiple small precision strips by means of a slitting knife block. Mini metal slitting machine is a small processing machine professionally designed for processing small-size coils, which can slit 0.2-0.3mm thick and 400mm wide coils into specified widths.

The mini metal slitting machine is mainly composed of uncoiler, slitter, waste collection device and winder, which can carry out the production process of tight slitting through the simple configuration of components, with the advantages of simple operation, small footprint, easy loading and unloading, as well as the advantages of economical features.

Technical Specification

| 1 | Material | Steel |

| 2 | Thickness | 0.23-0.35mm |

| 3 | Material width | ≤350mm |

| 4 | Coil outer diameter | ≤Φ1200mm |

| 5 | Coil inner diameter | Φ480mm-520mm |

| 6 | Production speed | 0-80m/min |

| 7 | Installed capacity | About 11KW |

| 8 | Control method | AC frequency conversion control |

Mini Metal Coil Slitting Machine Component

Decoiler

The metal coils to be slit are transferred to the decoiler via the loading system. The decoiler unwinds the coil and transports it to the working area of the slitter.

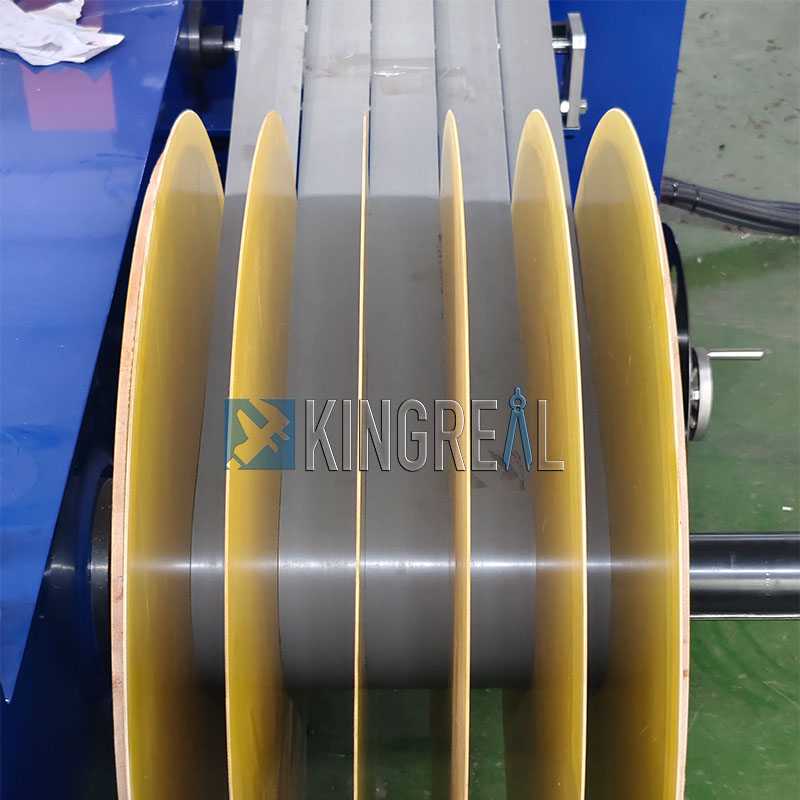

Slitting Machine

The web is transferred to the Slitting Tool, the heart of the slitting machine. The slitting tool usually consists of a number of blades arranged at preset width intervals. Through precise mechanical control, the blades rotate and cut the web into strips of the desired width.

Scrap Edge Device

The waste edge is generated by the slitter tool and is guided via a guiding device to the waste edge collection device. A winding device is usually provided to wind the waste edge into rolls for centralized handling and transportation.

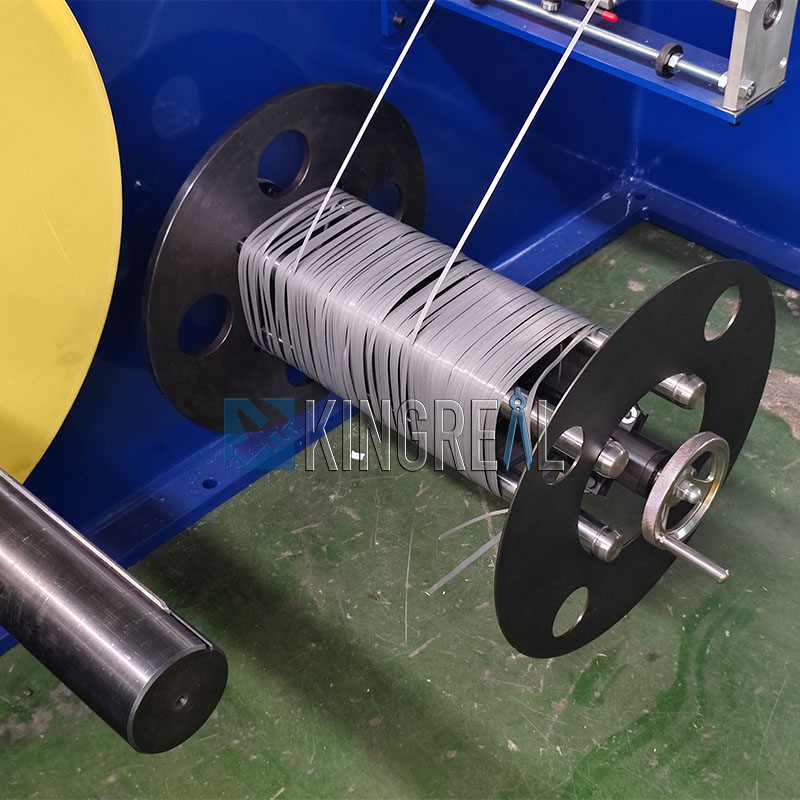

Rewinding Machine

The slit metal strips are transferred via a conveyor system to a rewinding for winding into new coils. Precise control of the rewinding ensures that each strip is wound tightly and uniformly on the winding spools, resulting in standard-sized coils for subsequent transportation and storage.

Advantage Of Mini Metal Coil Slitting Machine

High material utilization

With precise cutting and scrap edge collection devices, the Mini Metal Slitter maximizes material utilization and reduces the amount of waste generated during production. This not only reduces material costs, but also reduces the impact on the environment.

Flexibility

The Mini Metal Slitter is capable of handling many types of metal materials, including steel, stainless steel, aluminum and copper. This versatility makes it suitable for a wide range of applications, from small electronic components to the manufacture of precision mechanical parts.

Ease of operation

Equipment design usually takes into account ease of operation and user-friendliness. Automated settings and simple, intuitive operator interfaces allow operators to get up to speed quickly even with less training, improving production operability and safety.

Low maintenance costs

Since the components of the mini metal slitter are usually made of high quality materials, they are durable and have low maintenance costs. Meanwhile, the modular design makes it easier to replace parts and repair, reducing downtime and maintenance costs.

Space saving

The compact design of the mini metal slitter means it takes up less space, making it ideal for production environments where space is limited. This allows factories to be more flexible in arranging production layouts and improves overall productivity.

Application Of Mini Metal Coil Slitting Machine

Mini metal slitter is mainly used to accurately cut metal coils with a thickness of 0.2-0.3 mm into finer metal strips for a variety of fine processing scenarios. For example, electronics industry, medical equipment, precision machinery and optoelectronic industry.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil