KINGREAL SLITTING Manufacturing Machine

———

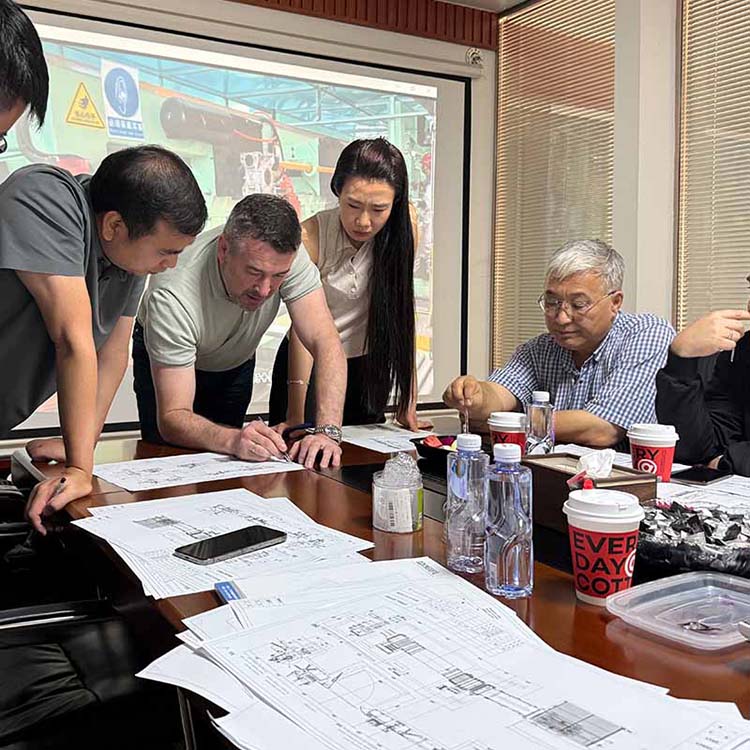

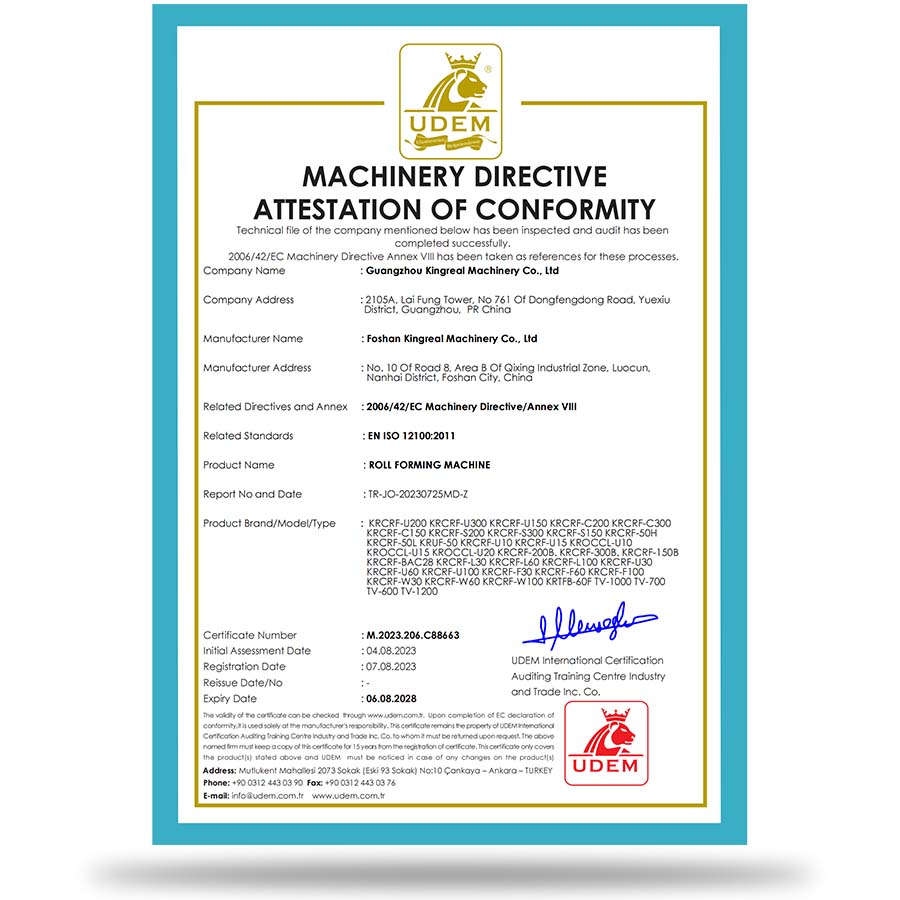

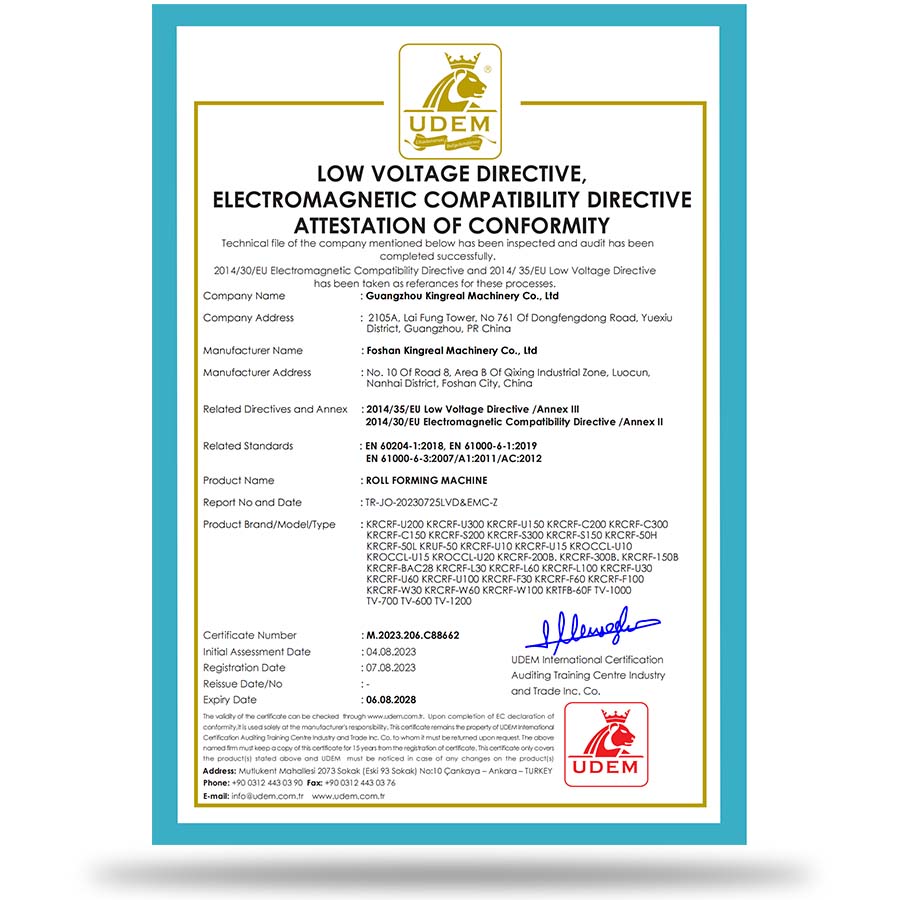

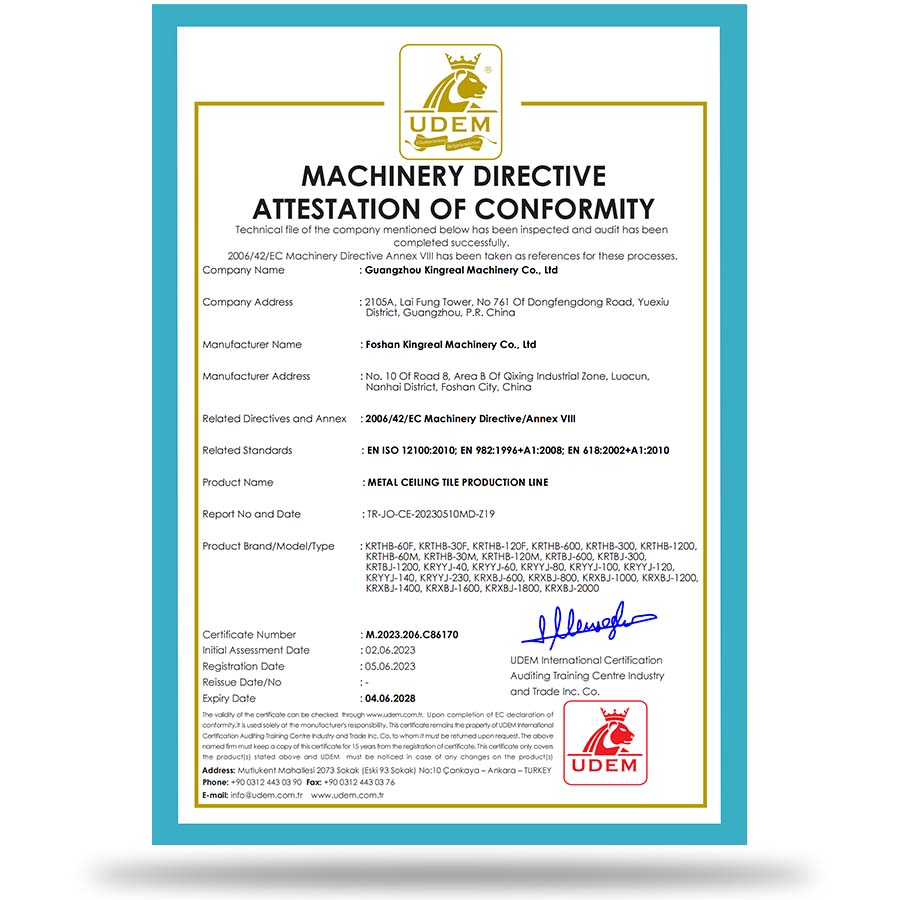

KINGREAL SLITTING is a team under KINGREAL MACHINERY that focuses on coil processing equipment design, manufacturing and service. From metal sheet forming, metal perforated machine to metal coil slitting and cut to length line, KINGREAL has been constantly exploring the field of metal coil processing and production equipment, and is committed to helping customers provide complete coil processing equipment production solutions to meet market needs. KINGREAL SLITTING is currently one of China's professional metal coil processing equipment suppliers, among which steel coil slitting line and cut to length machine are the most representative metal coil processing production line devices. Rich project experience can ensure that customers get the most matching metal coil processing equipment design, production and after-sales service and other services.

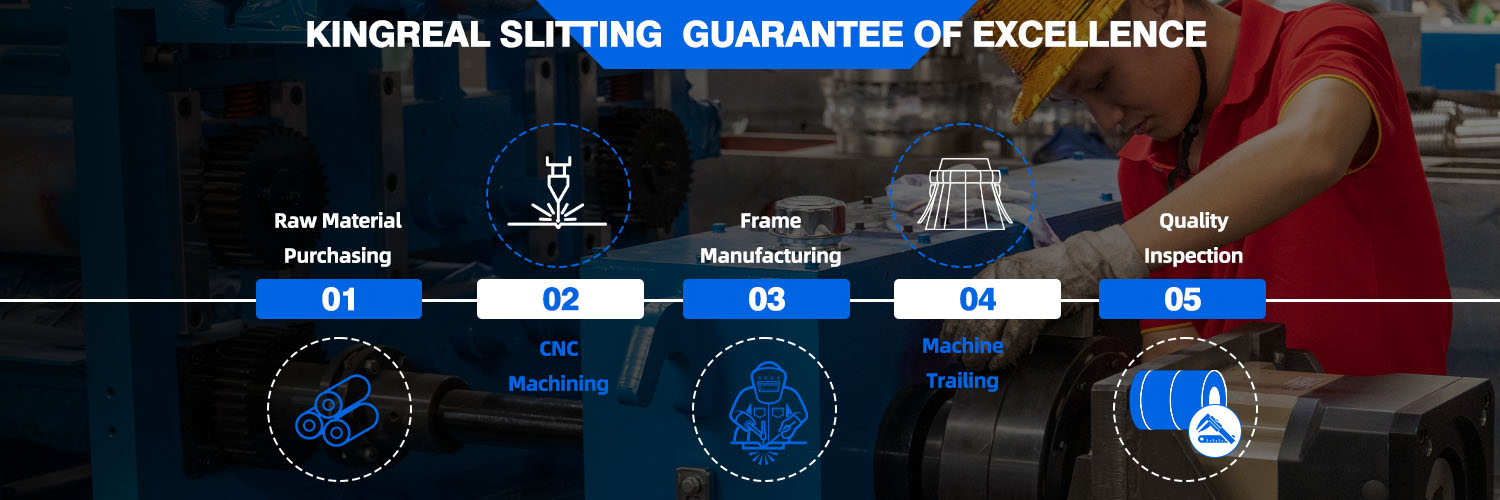

In the field of manufacturing metal slitting machines and cut-to-length lines, KINGREAL SLITTING is equipped with a team of specialized technicians to design production solutions based on the customer's production needs. With experienced production team, we control the progress and quality of production from raw material purchasing, CNC parts machining, frame structure casting to the commissioning and testing of the whole line.Complete quality inspection system, from the precision error of the processed products, voltage and power to the production speed, are in strict accordance with the quality control system.

So far, KINGREAL SLITTING has manufactured metal slitting machines and cut-to-length lines to meet the processing needs of different materials, including stainless steel, aluminum coils, hot rolled steel, cold rolled steel, silicon steel and copper coils, etc., with a range of thicknesses from 0.2-20MM and widths from 500-2000MM to meet the needs of more than 90% of the coil processing needs on the market.

●Coil Slitting Machine Solution

KINGREAL SLITTING can supply the whole solution for coil slitting machine, used to process metal coils of different raw materials with a thickness range of 0.2-16MM. According to the customer's slitting processing requirements, the strips are slid into strips of specified width and finally rolled up.

Simple coil slitting machine are used in a wide range of applications in the web processing industry to split a web into multiple small precision strips by means of a slitting knife block. Mini metal slitting machine is a small processing machine professionally designed for processing small-size coils, which can slit 0.2-0.3mm thick and 400mm wide coils into specified widths.

②Medium Gauge Coil Slitting Line

Medium Gauge Coil Slitting Line is a device specially designed for slitting and shearing coils of tinplate, galvanized iron, silicon steel sheet, cold-rolled strip, stainless steel strip and aluminum strip with a thickness range of 3-6MM. Medium Gauge Coil Slitting Line can accurately cut metal coils into strips of various predetermined widths and roll these strips into small coils for subsequent processes.

③Heavy Gauge Coil Slitting Machine

The Heavy Gauge Steel Slitting Line most important production feature is the ability to process thick or heavy gauge materials up to 20mm thick and 2000mm wide.It can slit common materials including hot rolled steel, cold rolled steel, coated steel, hot rolled black steel, etc., to meet the needs of different thicknesses, widths and slitting requirements.

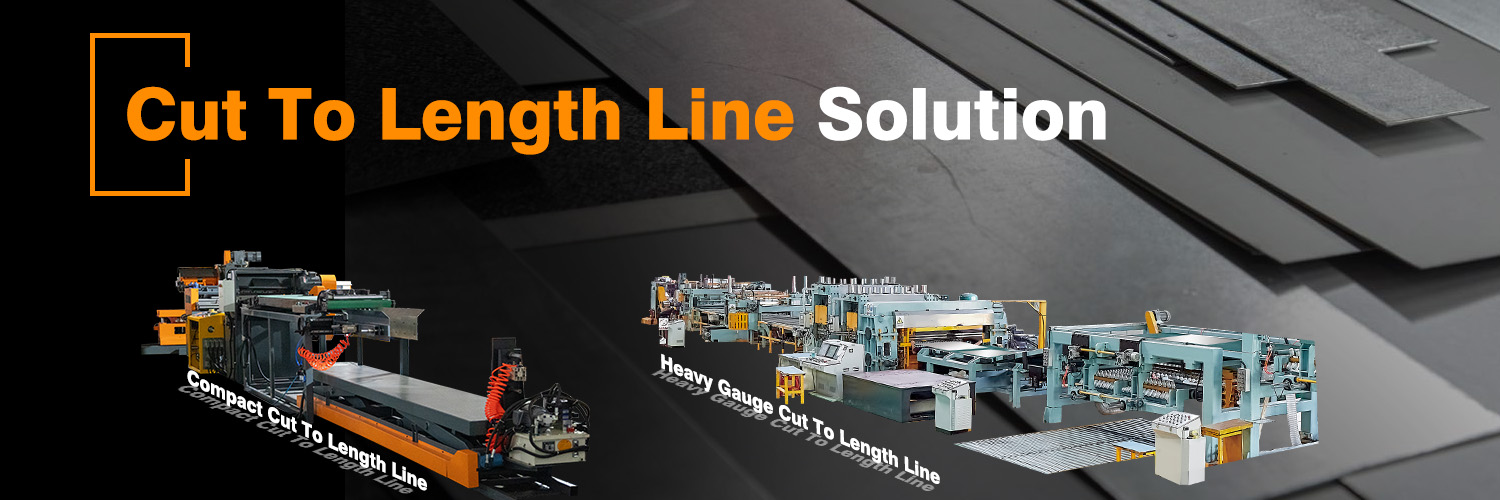

●Cut To Length Line Solution

Compact Cut-to-length shearing line is specially used in the field of coil processing and production to produce metal sheets of specified width through the process of leveling, shearing and stacking of metal coils to be put into secondary production.

②Heavy Gauge Cut To Length Line

Heavy Gauge Cut To Length Lines can flatting and cutting the large-size steel coil rolls, which thickness can reach 8-25mm, width can reach 900-2500mm. This is a major breakthrough of the cut-to-length line in the field of coil processing technology.Heavy duty cut to length line is capable of performing various functions including decoiler, straightener, measuring, shearing machine, and stacking. The compact cut to length line principle revolves around combining the functions of a coil line, decoiling, flattening, and feeding the material.

KINGREAL SLITTING Provide Service

———

KINGREAL SLITTING is committed to helping our customers realize breakthroughs in steel coil slitting line and metal cut to length production efficiency. Building a machine is the first step in a project, and providing better service to the customer is the direction that KINGREAL SLITTING has always been heading.

① KINGREAL SLITTING has a team of English and Russian speaking specialists who can help you understand your needs and answer your questions.

② Provide the best production solution design. Whether it's a Cut To Length Line or a Coil Slitting Line, KINGREAL SLITTING will customize a unique production solution based on a number of factors, including the size of the rolls to be processed, the volume of material to be processed, the characteristics of the local market, and the budget.

③KINGREAL SLITTING has a professional after-sales service team to help customers with the installation and commissioning of the line, as well as to provide professional operator training services, which will help to increase the service life of the line.

"KINGREAL SLITTING has always been committed to being a partner to our customers, helping them to improve their competitiveness in the marketplace and to gain long-lasting production benefits."