▎How To Choose The Coil Slitting Line?

Description Of Dual Slitter Head Slitting Machine

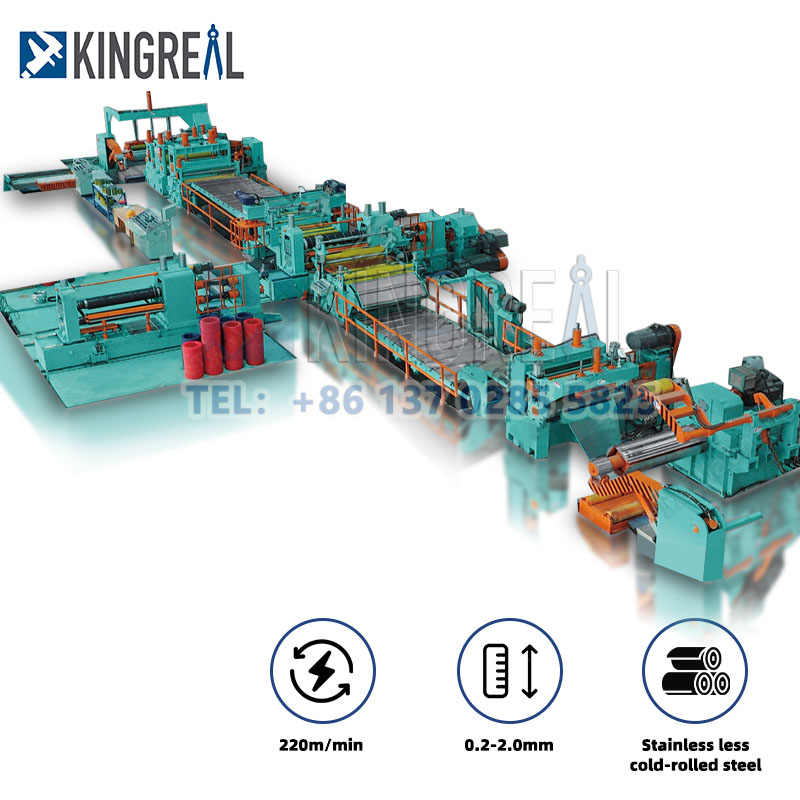

KINGREAL SLITTING, a leading coil slitting machine supplier in China, introduces the high speed slitting machine to meet the fast slitting needs of factories with large daily outputs. The KINGREAL Double Head High Speed Slitting Line is ideal for processing carbon steel, stainless steel, and pre-painted/coated coils. It handles thicknesses up to 3mm, maximum widths of 2000mm, and operates at speeds up to 220 m/min.

Factory production always puts safety first. Adapting to our customers needs for improving production safety, KINGREAL SLITTING especially designed a protective shield for coil slitting machines to ensure production safety.The high speed slitting line from KINGREAL SLITTING is designed to deliver exceptional performance, high efficiency, and superior quality, making it an indispensable tool for large-scale metal processing facilities.

Technical Specification Of Coil Slitting Machine

Material of raw materials: stainless steel, cold-rolled steel.

Raw material thickness: 0.2mm-2.0mm

Raw material width: 300-1550mm

Raw material roll inner diameter: Φ508mm

Raw material roll outer diameter: ≤Φ1800mm

Raw material volume weight: ≤12 tons

Slitting speed: up to 220m/min

Total power: about 150KW

Floor area: about 18m × 6m

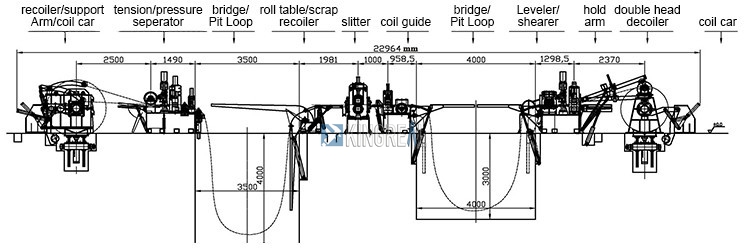

High Speed Slitting Line Component List

List | Equipment Name | Qty |

| 1 | Optional Coil Load Trolley | 1 Unit |

| 2 | Hydraulic Decoiler | 1 Unit |

| 3 | Hydraulic Assist Support | 1 Unit |

| 4 | Loop Bridge | 1 Unit |

| 5 | Guide Align & Main Coil Slitting Machine | 1 Unit |

| 6 | Scrap Collector | 1 Unit |

| 7 | Loop Bridge | 1 Unit |

| 8 | Loop Bridge | 1 Unit |

| 9 | Hydraulic Tension Station | 1 Unit |

| 10 | Hydraulic Assist Support | 1 Unit |

| 11 | Vertical Press Arm Hydraulic Recoiler, Pushing Device | 1 Unit |

| 12 | Hydraulic System | 1 Unit |

| 13 | Electrical Control System | 1 Set |

| 14 | Optional Protect Shield | 1 Set |

High Speed Slitting Machine Component Details:

Decoiler with Coil Car For Slitting Line : Efficiently unwinds coils, supported by a robust coil car for handling large rolls.

Clamping and Shearing Device For High Speed Slitting : Provides secure material handling and precise shearing.

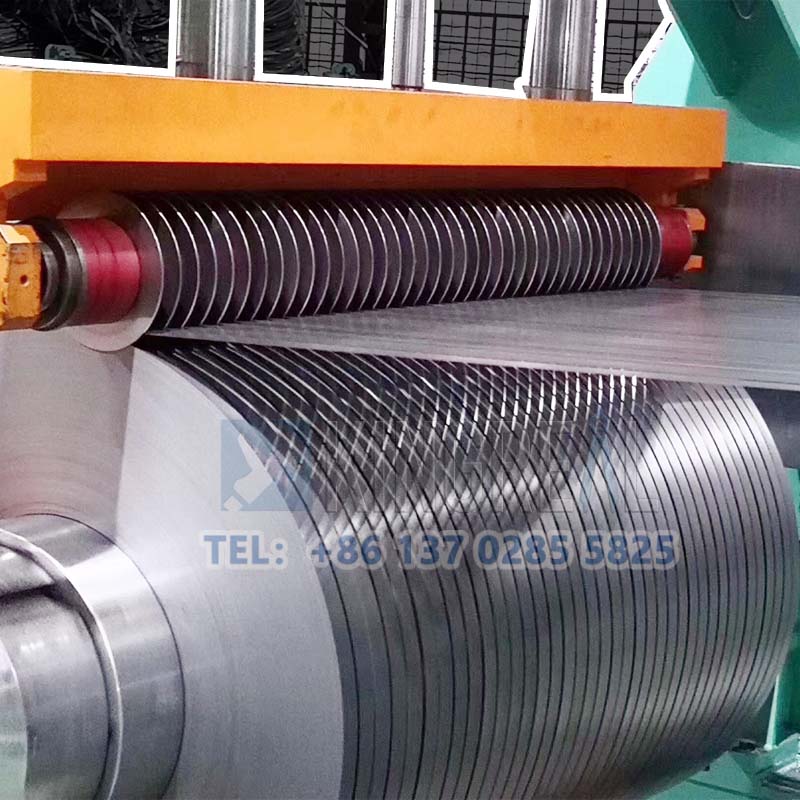

High-Precision Slitter for Quick Exchangen For Slitting Machine: Ensures rapid and accurate slitting with easy tool changes.

Waste Rewinding System For Steel Slitting : Effectively collects and rewinds waste material for a clean working environment.

Side Guide For Slitting Line : Maintains material alignment for precise slitting.

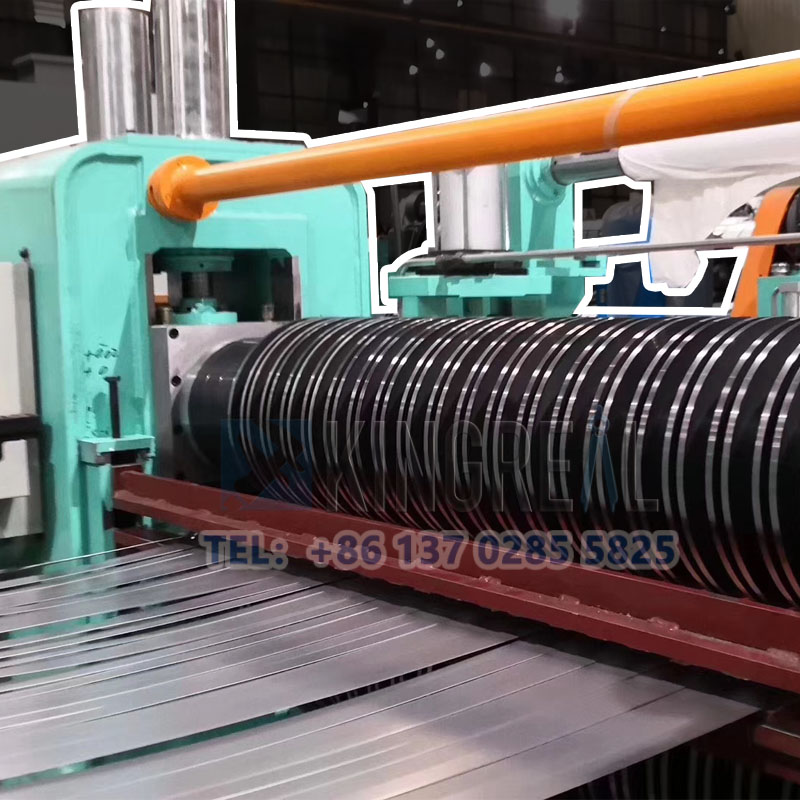

Winding Machine and Tension Device For High Speed Slitting: Ensures tight and even winding of slit coils, maintaining optimal tension throughout the process.

Hydraulic Winder with Coil Car For Steel Slitting :Facilitates efficient winding and easy handling of finished coils.

Working Processing Of High Speed Coil Slitting Machine

Coil loading Trolley → Hydraulic Decoiler → Pinch Straightener → Pit Loop → Coil Side Guider → Guide Align / Disc Slitting → Side Scrap Collector → Pit Loops → Tensioner → Rewinder Machine → Coils Unloading → Finished Products

Advantage Of Dual Slitter Head In The Coil Slitting Machine

1. Flexible Production For High Speed Slitting

The dual slitter head design in the high speed slitting machine offers unparalleled flexibility in production. The heads can be configured identically or varied, with one head larger and the other smaller. This allows for the slitting of both thick and thin materials on the same machine. For instance, the larger slitting head is ideal for processing thicker coils, while the smaller head handles thinner coils efficiently. This versatility ensures that the machine can achieve high-precision and high-efficiency performance, catering to a wide range of material specifications.

2. Labor Efficiency For Dual Slitter Head Slitting Line

One of the significant advantages of the dual slitter head design is its contribution to labor efficiency. The ability to quickly change slitter heads with minimal effort means that a single operator can perform the task, reducing the need for multiple personnel. This not only saves labor costs but also streamlines the production process, minimizing downtime and maximizing operational efficiency.

3. Enhanced Productivity For Steel Slitting Line

By enabling quick and easy changes between slitter heads, the high speed slitting line ensures continuous production with minimal interruptions. This feature is particularly beneficial for large-scale operations that require frequent adjustments to accommodate different coil sizes and thicknesses. The result is a substantial increase in overall productivity and a more efficient use of resources.

4. Precision and Consistency For Steel Slitter

The dual slitter head configuration allows for precise control over the slitting process. Each head can be fine-tuned to meet specific requirements, ensuring consistent quality and accuracy in the finished product. This level of precision is crucial for industries that demand exacting standards, such as automotive, aerospace, and electronics.

FAQ:

1. What is a coil slitting machine?

A coil slitting machine is a device used to cut wide metal coils into narrower strips. These strips can be further processed or used directly in various applications.

2. What are the main components of a coil slitting machine?

The main components of a coil slitting machine typically include:

Decoiler: Used to uncoil and hold the metal coil.

Slitter: The cutting tool that slices the metal coil into strips.

Recoiler: Rolls the cut strips into new coils.

Tension Control System: Ensures the strips maintain proper tension during processing.

Side Guide: Keeps the strips aligned for precise cutting.

Waste Rewinding System: Collects and rewinds the scrap edges.

3. How does a coil slitting machine work?

The working principle of a coil slitting machine involves the following steps:

Uncoiling: The metal coil is uncoiled by the decoiler and fed into the slitter.

Slitting: The slitter's rotating blades cut the coil into strips.

Tension Control: The tension control system maintains the proper tension on the strips during processing.

Recoiling: The recoiler winds the cut strips into new coils for easy handling and storage.

4. What are the advantages of a coil slitting machine?

The main advantages of a coil slitting machine include:

High Precision: Ensures the cut strips have high dimensional accuracy.

High Efficiency: Automated control systems enhance production efficiency.

High Material Utilization: Waste is minimized through effective scrap collection, improving material usage.

Flexibility: Capable of processing various metals, suitable for diverse applications.

Ease of Operation: Automated settings and intuitive interfaces make the machine user-friendly.

Low Maintenance Cost: Made from high-quality materials, these machines are durable and have low maintenance costs.

5. How to get a quote?

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you

l Coil Material

l Coil Thickness

l Coil Width

l Coil Weight

l Slit Width

l Slit Speed

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil