How To Use The Aluminum Coil Slitting Line?

Description Of Aluminum Steel Coil Slitting Line

As aluminum coil has a lightweight and high strength, corrosion and weather resistance and good electrical and thermal conductivity and other characteristics, widely used in aluminum coil is widely used in electronics, packaging, construction, machinery and many other fields. Therefore, as one of the most important processing equipment for aluminum coils, aluminum coil slitting machine aluminum coil slitting machinery and equipment through the row of knives to achieve the original aluminum coil is divided into the specified size of the aluminum strip, which helps to improve the production efficiency, save aluminum, to ensure the quality of aluminum.

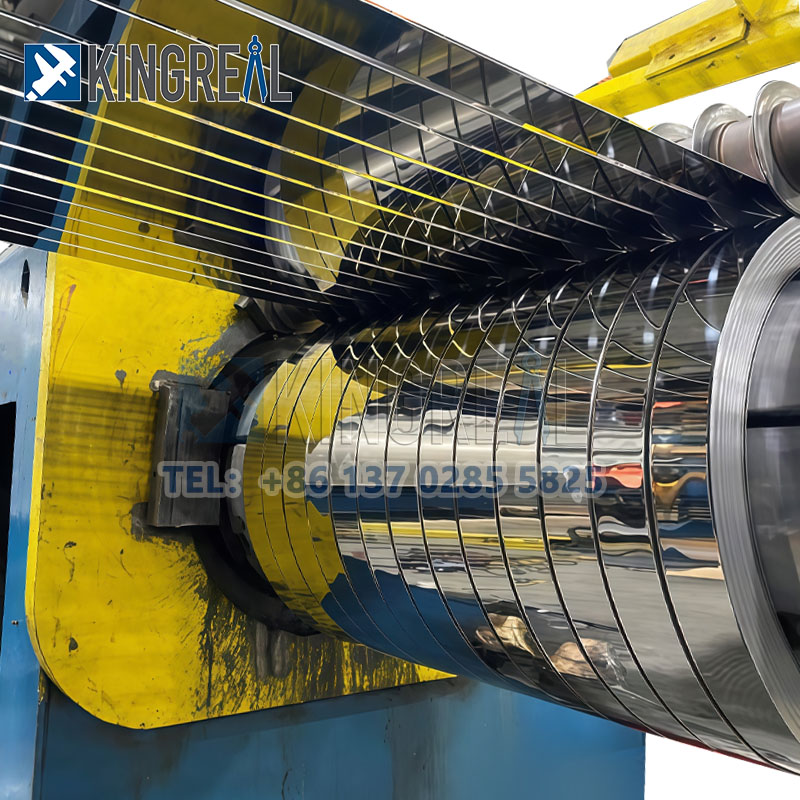

The standard configuration of KINGREAL SLITTING aluminum coil slitting line includes decoiler, leveler, slitter, scrap collection, tension station and rewinding, etc., which is used for the process of aluminum coil processing, and it has the advantages of fast production speed, accurate shear size, and it can realize the advantages of one-button start, remote control and other characteristics.

Working Process Detail Of Aluminum Steel Coil Slitting Line

1. Coil loading

First, the aluminum coils are transported precisely to the center of the unwinder by means of a loading trolley. This process ensures that the coils are consistently and safely fed into the subsequent processing machines.

Key equipment: Coil Car and Uncoiler

2. Head handling and leveling

The front end of the coil is fed into the leveling machine for leveling process by using the feeder. The leveled sheet passes through the center conveyor into the guiding machine to ensure that the sheet is centered and neat before it enters the sizing machine. Then, according to the pre-set standards, irregularities are cut off by the hydraulic head shears to ensure the flatness and dimensional accuracy of the plates.

Key equipment: Feeder, Straightener, Centering Device, Length Measuring Device and Hydraulic Shear.

3. Edge cutting and scrap collection

Guided by the lateral guiding mechanism, the sheet enters the trimming machine and is cut into predefined specification strips. Waste edges generated during the cutting process are collected by a wire drawing machine, ensuring a clean work area and efficient material utilization.

Key equipment: Side Guide, Edge Trimming Machine and Scrap Winder.

4. Tension Control and Winding

After edge trimming, the strip passes through the live buffer device and enters the tension station. The required winding tension is established with the winder through the tension device to ensure the tightness and flatness of the web during the winding process and to prevent the web from collapsing or coming loose.

Key equipment: Loop, Tension Station and Rewinding.

5. Unloading of rolled material

After completing the winding, the rolled material is unloaded from the winding shaft by the unloading mechanism and transferred to the out-feed trolley. Finally, the unloading trolley transports the rolled material out to the designated storage or transportation area.

Key Equipment: Unloading Device and Exit Coil Car.

Feature Of Aluminum Slitting Machine

1. Fuselage structure: the fuselage is welded with high-quality steel plate and processed through strict heat treatment to ensure that the equipment has excellent strength and rigidity. This design not only improves the durability of the equipment, but also extends its service life, so that it can operate for a long time in a high-intensity working environment without being easily deformed or damaged.

2. Customized equipment power: according to the user's capacity needs, equipment power can be flexibly customized. Whether it is small-scale production or large-scale continuous operation, the equipment can adapt to different production requirements, support 24-hour uninterrupted operation, so as to fully meet the user's output requirements.

3. Frequency converter drive: the equipment adopts frequency converter drive mode, and the production speed can realize infinite speed regulation. By adjusting the frequency converter, the production speed can be precisely controlled to ensure the stability of the production process and the high quality of the products.

4. Auxiliary support arm: The rewinding is equipped with an auxiliary support arm designed to carry high tonnage coils. This configuration is especially suitable for the production of large coil unwinding, to ensure a smooth and stable unwinding process, to avoid the coil falling or shifting during the unwinding process.

5. Belt tension station: After slitting, you can choose to adopt belt tension station, which is used to improve the precision of rewinding and protect the surface of the coil. The belt tension station can effectively control the winding tension, prevent the coil from being loose or damaged during the winding process, and ensure the quality and appearance of the final product.

6. Scrap edge collection system: The equipment provides a perfect scrap edge collection system, which realizes integrated process management from automatic scrap edge rewinding to material transportation. The system can efficiently collect and process the waste materials generated during the trimming process, keep the working environment neat and tidy, and improve the production efficiency.

7. Intelligent monitoring system: the whole line of aluminum coil slitting machine can be optionally equipped with intelligent monitoring system to ensure the safety and accuracy of the slitting process. Intelligent monitoring system can monitor the running status of the equipment in real time, adjust the parameters automatically, provide fault warning and remote diagnosis functions to ensure the high efficiency and safety of the production process.

What Is The Aluminum Coil Slitting Line Can Do?

Coil Thickness: 0.3-3MM

Material width: 500-2000mm

Coil outer diameter: ≤Φ1800mm

Coil inner diameter: Φ508mm

Max weight of coil: 25T

How To Choose The Coil Slitting Machine Manufacturing?

How to choose the coil slitting line is a problem that most factories will face. From their own point of view, clear processing needs as well as the output and factory positioning for the procurement of the metal slitting line will be of great help. From the supplier's point of view, in addition to price, the more important thing is the degree of professionalism, production capacity, supply capacity, after-sales ability and production experience and so on.

Face-to-face communication is more conducive to building trust between suppliers and customers. KINGREAL SLITTING, as one of the professional coil processing manufacturers, welcomes all customers to come and visit our factory to learn more about our production strength and technology.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil