Video About (0.4-5)×1650MM Coil Slitting Machine

Metal Slitter Machine

KINGREAL SLITTING offers a diverse range of metal slitter machines for sale, including advanced Steel Coil Slitting Lines. These comprehensive slitting lines integrate mechanical, electrical, hydraulic, and pneumatic automatic controls, encompassing uncoiling, straightening, slitting, cross-cutting, and winding, all synchronized to ensure efficient operation. The entire set of equipment is designed with various over-riding roll conveyors to meet the high surface quality requirements of the processed materials.

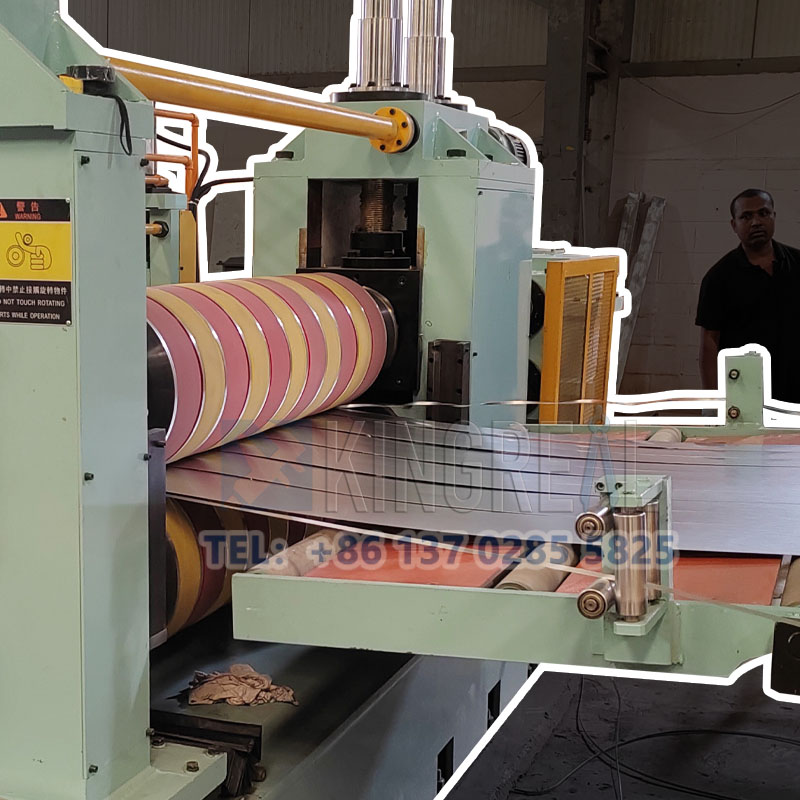

KINGREAL SLITING employs the latest slitting technology, ensuring that slitting operations do not cause indentations, scuffing, scratching, folding, or edge biting on the metal coils. As one of the most professional metal slitting machine manufacturers in the industry, we offer a variety of slitting line machines, including double slitter head slitting lines, automatic PPGI coil slitting machines, and steel slitter. KINGREAL SLITTING can customize coil slitting machines to meet the specific needs of our customers.

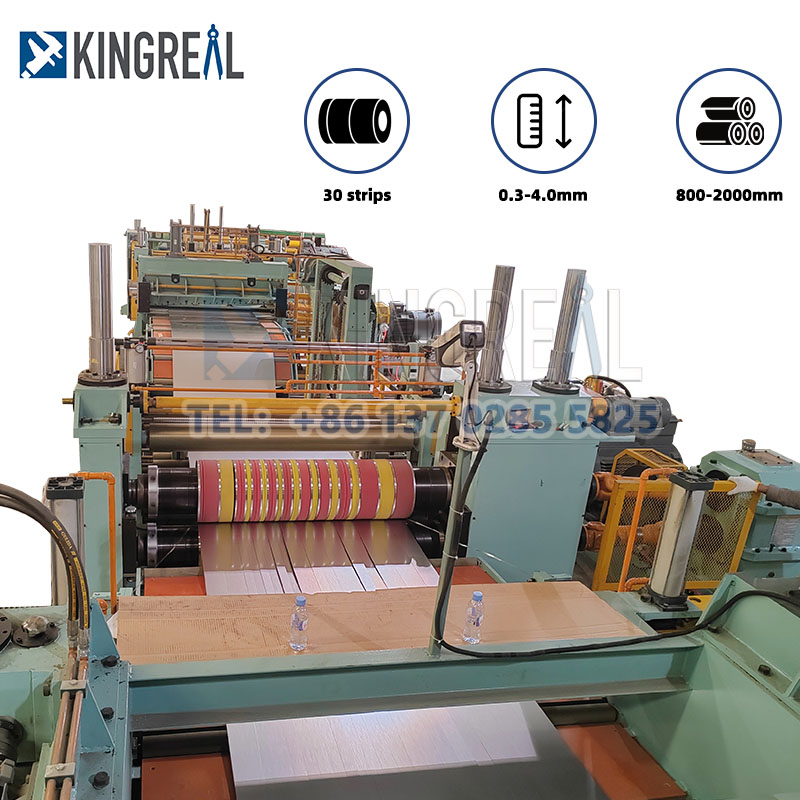

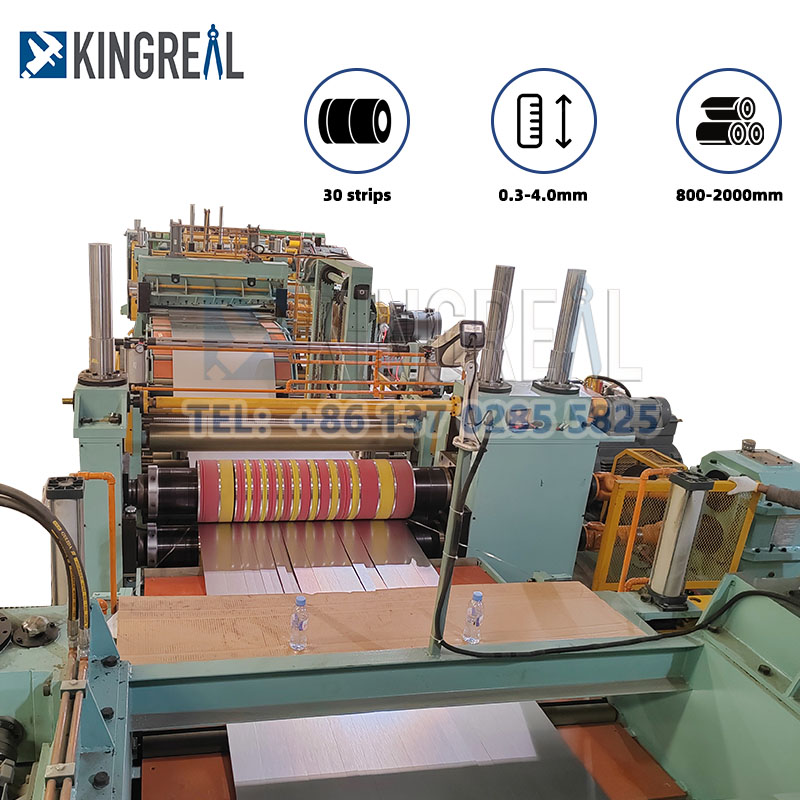

(0.4-5)×1650MM Coil Slitting Machine

The most notable advantage of the (0.4-5)×1650MM Coil Slitting Machine lies in its wide market applicability and its precision slitting capabilities. This machine is designed to handle a diverse range of applications across various industries due to its ability to process metal coils with thicknesses ranging from 0.4mm to 5mm. Its advanced technology ensures high-precision slitting, which is critical for producing narrow strips with exact dimensions and minimal error.

Additionally, the (0.4-5)×1650MM Coil Slitting Machine excels in efficiently processing metal coils, including steel, aluminum, and other materials. This versatility makes it a preferred choice for manufacturers who require reliable and consistent performance to meet the varying demands of their customers. The integration of mechanical, electrical, hydraulic, and pneumatic controls ensures seamless operation from uncoiling to winding, enhancing productivity and maintaining the high surface quality of the processed materials. This makes the (0.4-5)×1650MM Coil Slitting Machine an indispensable tool in the metal slitting industry, known for its superior accuracy and extensive application range.

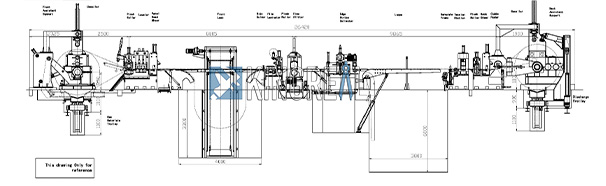

Main Process of Steel Slitting Line Machine

Upload Material -- Decoiler -- Clip Feed Leveler/Shearer -- First Loop Bridge -- Guide and Slitting -- Scrap Collection -- Second Loop Bridge -- Tension Machine -- Uncoiler Slitted Coil -- Unload Coils

Composition of Complete Coil Slitting Line

No | Name | Qty |

| 1 | Material storage table(optional) | 1 pair |

| 2 | Feeding trolley | 1 set |

| 3 | Double cone Uncoiler + Recoiler | 1 set |

| 4 | 1# Bridge | 1 set |

| 5 | Guiding device | 1 set |

| 6 | Slitting machine | 1 set |

| 7 | Material transition device | 1 set |

| 8 | Integral edge trimmer | 1 set |

| 9 | Integral edge trimmer | 1 set |

| 10 | Tensioner | 1 set |

| 11 | Winding machine (with separating frame | 1 set |

| 12 | Unloading trolley | 1 se |

| 13 | Hydraulic system | 2 sets |

| 14 | Pneumatic system | 1 set |

Features of Steel Coil Slitting Machine

1. Latest slitting technology

KINGREAL adopts a new patented technology taper tension anti-scratch tension mechanism control system, which solves the problem of tension scratch and winding characteristics. Adopting the newly developed horizontal drive winding mechanism by our technical team, which solves the gear lubrication problem of winding mechanism.

2. Easy operation

High-speed cantilever uncoiling mechanism, using the ground to uncoil, reducing the pain of digging pits. Adopting a spacer type round shear, on which a locking type blade can also be installed, making it a dual-purpose round shear.

Adopt the airbag type pressing to ensure to keep the balanced tension in different thicknesses.

3. Flexible solutions

As a professional metal slitting machine supplier, it is important to always work in concert with the end customer so that the components, dimensions, tooling, horsepower and tension in the machine are appropriate for the material to be slit. With our rich experience in slitting machine manufacturing, KINGREAL can offer alternative solutions for our customers on our metal slitter according to their production requirements.

Application Of Steel Coil Slitting Machine

Most of these smaller strips are used in the manufacturing of transformers, motor manufacturing industry, tube/tube welding plant industry, next process use industry in specialized fields such as cold rolling forming industry, ceiling plasterboard industry and other high precision equipment manufacturing and metal strip manufacturing industry.

According to customer’s requirements, automatic coil slitting machines in special sizes and special raw materials can be produced by KINGREAL SLITTING.

FAQ About Coil Slitting Line:

·Can One Metal Slitter Process Coils Of Different Sizes?

Absolutely! One of the main advantages of metal slitting machines is their flexibility and versatility, being able to handle metal coils of various widths, thicknesses and materials. A metal slitter can precisely cut wide metal coils into narrower strips as needed. Common coil widths include 800mm, 1600mm, 2000mm, etc. By adjusting the tool combination, the width of the cut product can be flexibly changed to meet different production needs.

A wide range of metal coils from thin to thick can be handled. For example, (0.4-5)×1650MM Coil Slitting Machine can handle coils ranging in thickness from 0.4mm to 5mm. This makes them ideal for a variety of industry applications, from the manufacture of electronic components to automotive parts.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil