Cut To Length Line

1/Providing Complete Cut To Length Production Line Solutions

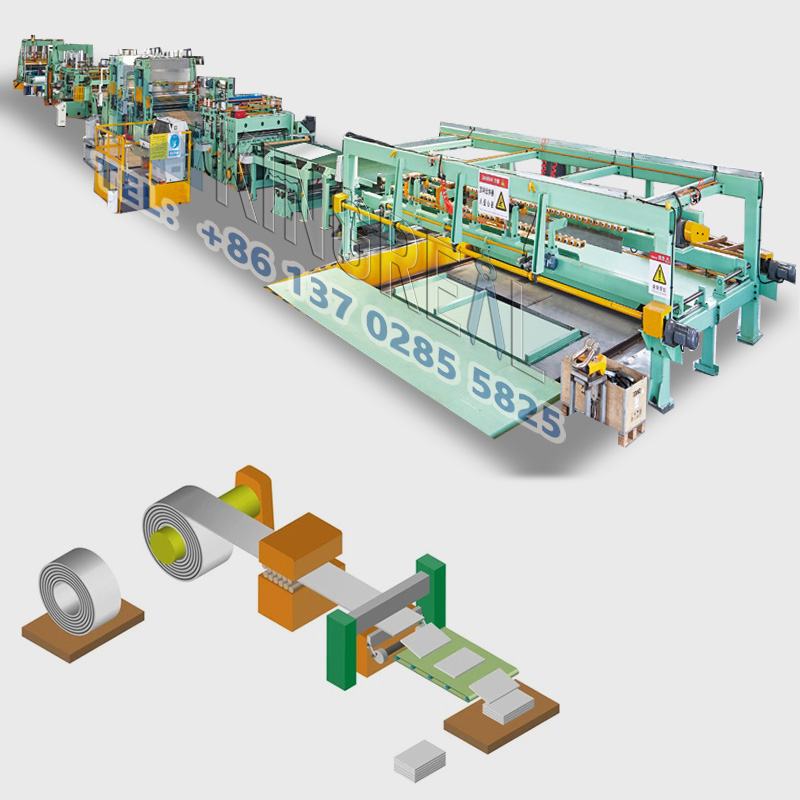

KINGREAL SLITTING Cut To Length Line is one of the metal coil processing equipment, designed to uncoil, level, cut-to-length, stack and other production processes for metal coils of different material thicknesses to produce metal sheets of specified widths. Cut-to-length lines are usually used for processing cold/hot rolled carbon steel, silicon steel, stainless steel, tinplate and surface plating of different materials such as metal coils, with thicknesses ranging from 0.2-25MM, to meet the needs of automobile manufacturing industry, steel processing industry and electric power industry, etc. for the metal sheet. KINGREAL SLITTING is committed to providing its customers with complete cut to length line production solutions, not just repeatable fixed equipment. Typically KINGREAL SLITTING will design a cut to length line that best matches the customer's coil processing needs, application, plant size, budgetary commitment and throughput requirements.

In 2024, KINGREAL SLITTING has helped customers in Brazil, Saudi Arabia, Indonesia, the United States and the United Kingdom to complete the design, manufacture, commissioning and installation of cut to length lines, which has been widely praised by customers. We are looking forward to a long and stable relationship with our customers to create production benefits and long-term development!

2/How To Choose The Cut To Length Line?

“KINGREAL SLITTING has many different types of cut to length line, including heavy gauge cut to length line, light gauge cut to length line, compact cut to length machine, full auto cut to length line and others, as a buyer, how to choose the right metal cut to length line for yourself? What is the difference between all these cut to length line solutions?”

◎Define Coil Processing Needs

How to choose the right metal cut-to-length line the first step needs to be clear coil processing needs, such as coil raw materials, thickness, width, roll weight, shear production needs, shear width, speed.

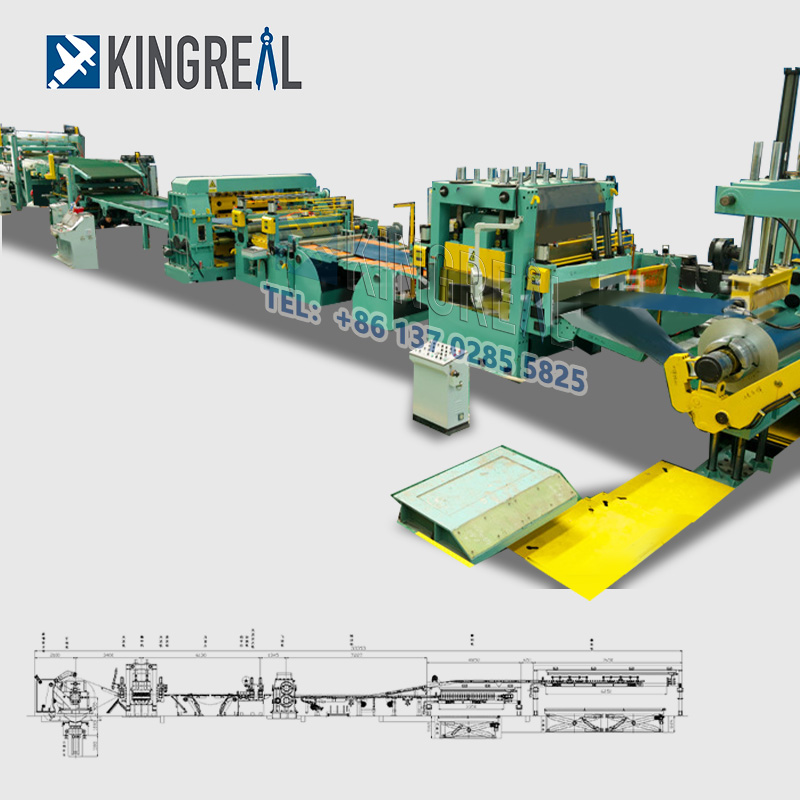

For the metal coil cut-to-length line, different metal raw materials have different material properties, in the cut-to-length line configuration needs to follow up on the coil processing needs for design. For example, silicon steel cut-to-length line produced by the silicon steel sheet needs to be high-precision fixed-length shear, for transformer cores or motor parts, the requirements of the shear section without burrs to avoid hysteresis loss, cut-to-length line setup needs to be equipped with 6-8 sets of roller leveling machine structure to eliminate the coil internal stress. Stainless steel cut-to-length line is usually a higher demand for surface treatment, will be equipped with a coating device to protect the surface of the raw material, shear blades using carbide to reduce wear and tear!

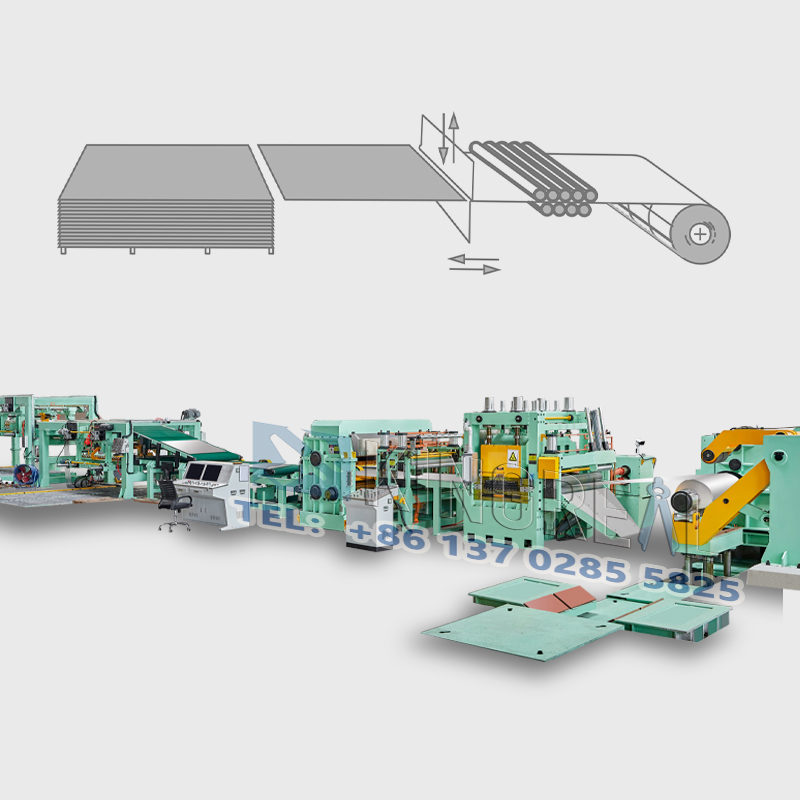

There are different configurations for different thicknesses of raw metal. For example, 0.2-3MM thin plate sizing shear line, usually using lightweight leveling rollers, shears using flying shears or pneumatic shears to increase speed, production speed can reach 80M / Min. 6-25MM heavy-duty sizing shear line equipped with a heavy-duty four-roller leveling machine and a hydraulic gate-type shearing machine to meet the demand for thick plate coil processing!

◎Clarify output and budget

Different coil processing needs such as shear speed and full automation will determine the design and price of the entire line of cut-to-length metal shearing lines. Buyers who want to buy the right metal shearing line can evaluate the metal sheet processing output requirements, plant size and labor costs and other dimensions to help choose the best metal shearing line production solutions.

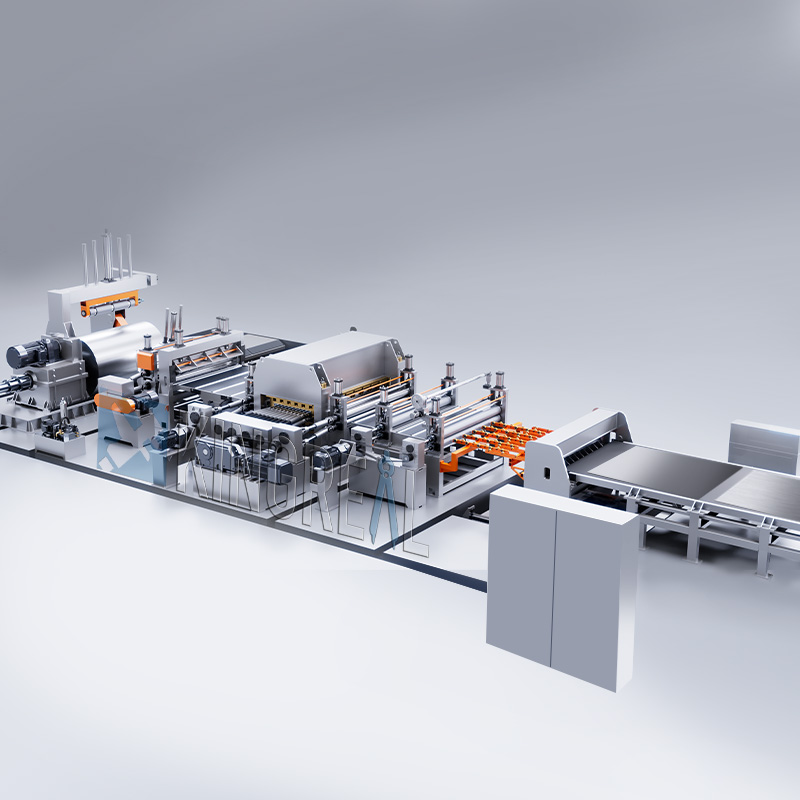

For example, in order to help customers with high throughput requirements, KINGREAL SLITTING has designed a fully automated metal cut-to-length line, equipped with servo feeder and high-speed flying shear to achieve a height of 80M/min, double stacking tables for fully automated palletizing and to match the speed of high-speed production, with integrated laminating, scrap recycling, and smart palletizing functions, which reduces the cost of a single piece.

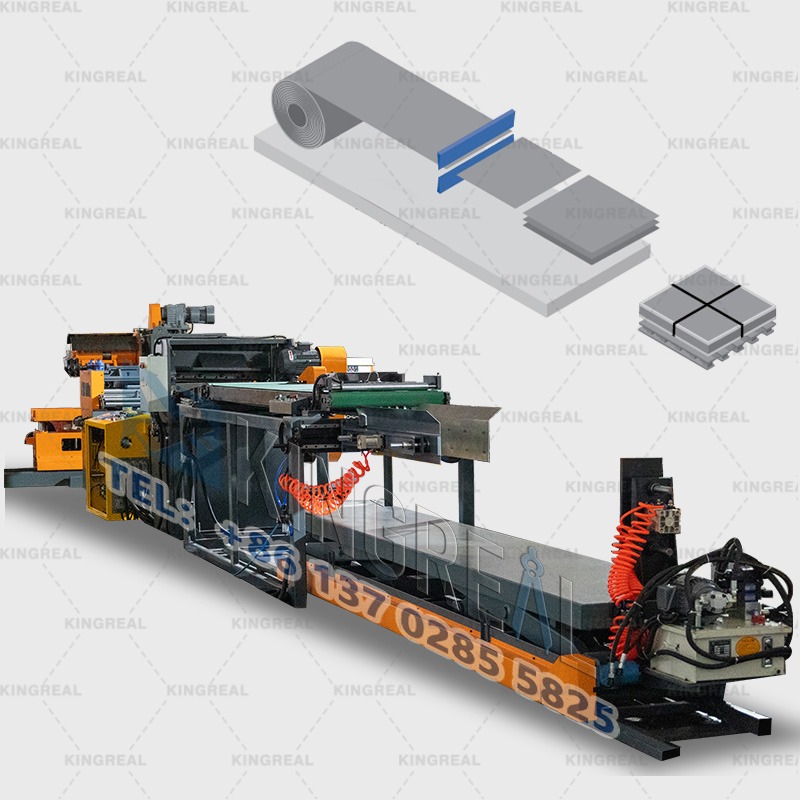

For customers with low production volumes and low budgets, KINGREAL SLITTING has designed a compact cut-to-length line with a basic leveler and a mechanical shear to meet the needs of cutting coils with thicknesses of 0.2-2MM, while reducing the footprint of the line by eliminating components and streamlining the process to reduce budgeted production costs.

◎Choose a professional supplier

The metal cut-to-length shearing line has a long production line. Component devices, processing precision requirements of high characteristics, choose a professional supplier to ensure the quality of the machine, shear processing precision and after-sales installation services and operation of the teaching, etc., to reduce the risk of procurement, then how to choose a professional supplier of metal shearing line?

First of all, whether there is a wealth of project experience, there are enough professional to be able to complete the design, production and installation process of metal shearing line. KINGREAL SLITTING has completed projects in dozens of countries such as Italy, Russia, the United States, Brazil and Saudi Arabia, welcome to contact us! Contact us!

Whether it can provide a strict quality control system. Non-specialized suppliers of cut-to-length shearing line may have high equipment failure rate or unqualified finished products due to lack of technology. A professional supplier of cut-to-length shearing line will measure the steel coil (tolerance, width, material) to multi-dimensional inspection after leveling (length, diagonal, surface quality) to avoid defective products flowing into the downstream process.KINGREAL SLITTING builds a systematic quality control system, and then conducts the process of line test in the factory after the machine is finished manufacturing and invites the customers to visit us.

KINGREAL SLITTING provides both online and offline after-sales service, answering customer's installation and operation questions online, and providing operating instructions and installation videos of the cut-to-length line. Offline can arrange the after-sales engineers to go to the customer's local factory for on-site installation and operation guidance.

3/How Many Types Of Cut To Length Line?

"Cut-to-length lines are one of the most common coil processing equipment, designed to process metal coils of different materials and thicknesses into sheets for secondary production. Depending on the characteristics of the metal raw materials, thickness, and design of the production line, cut-to-length lines can be divided into the following types:"

Cut To Length Line For Different Thickness Coil

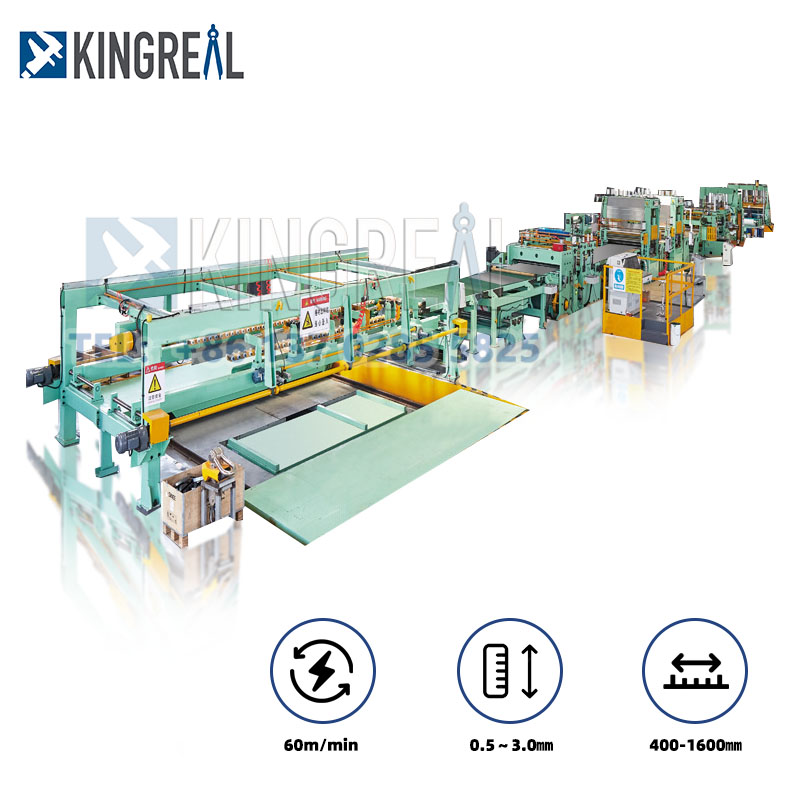

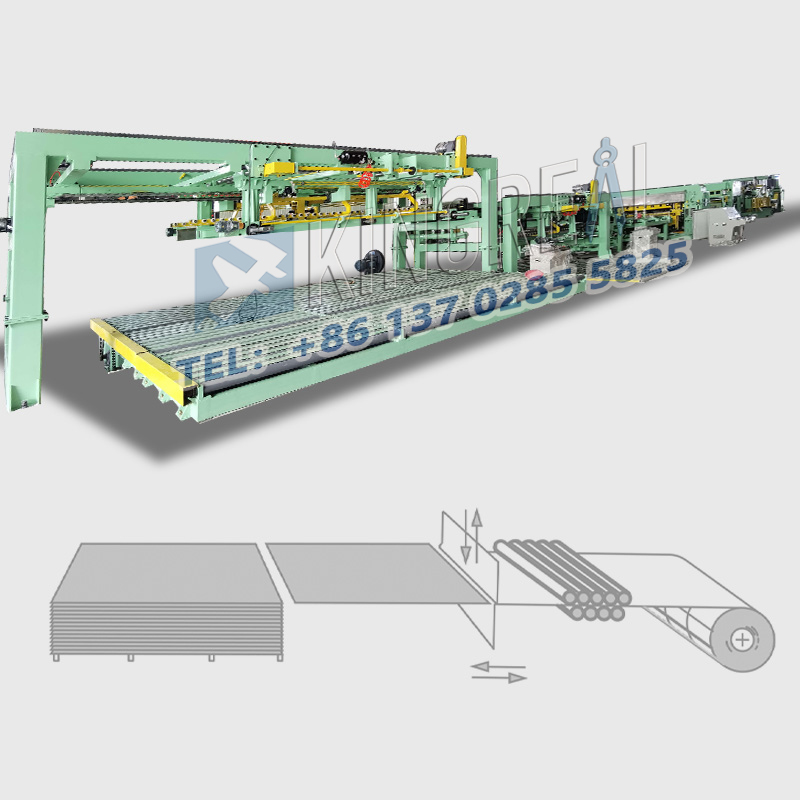

1, Compact Cut To Length Line (Light Gauge Cut To Length Line) :Compact cut-to-length line, light cut-to-length line is specially designed for processing 0.2-3MM metal coil thickness. Generally speaking, this type of cut-to-length line can complete the production needs of metal coils into sheets by unwinding, leveling, cut-to-length shearing and stacking. bCompact cut-to-length line is one of the best choices for production workshops and customers with limited budgets. It can realize the processing and production of metal coils through the simplest device. At present, KINGREAL SLITTING compact cut-to-length line has completed the production and installation of projects in countries and regions such as Russia and Brazil.

2, Heavy Gauge Cut To Length Line: The design of the heavy gauge cut to length machine meets the processing and production needs of metal coils with a thickness range of up to 25MM. The four-roller leveling technology eliminates plate stress, the hydraulic servo shearing system achieves millimeter-level accuracy, and the automatic stacking design adapts to the processing of plates of different sizes. The thick plates processed by the heavy gauge cut to length machine are widely used in the fields of infrastructure, transportation manufacturing, and energy and chemical energy.

Cut To Length Line For Different Coil Material

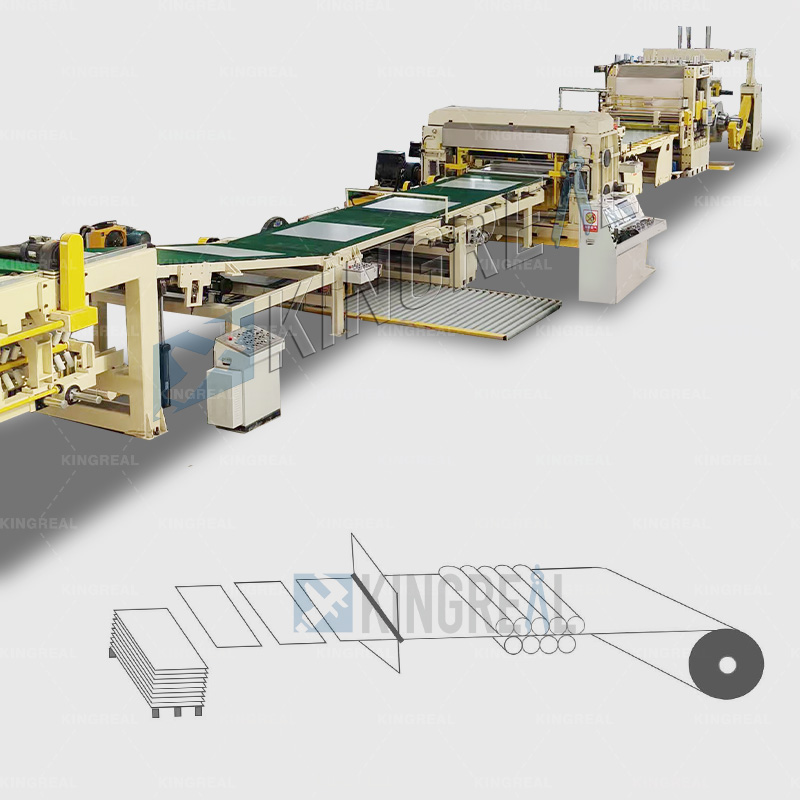

1, Stainless Steel Cut To Length Line: The stainless steel cut-to-length shearing line is a production line specially designed for processing stainless steel metal coils with a thickness of 0.3-6.0mm and a width of 150-2600mm. It is cut into customer-specified widths and then automatically stacked. In order to improve the precision of stainless steel coil processing, the stainless steel cut-to-length shearing line is designed with servo motor and PLC linkage control, and the position full closed-loop system eliminates the slip error of the traction roller. The cut-to-length shearing accuracy can reach ±0.1mm.

2,Other different type cut to length machine including the metal cut to length line, tinplate cut to length line and silicon coil cut to length line. According to the characteristics of different metal coils, KINGREAL SLITTING will make customized designs and adjustments when designing the cut-to-length line solution.

Cut To Length Machine For Different Shearing Type

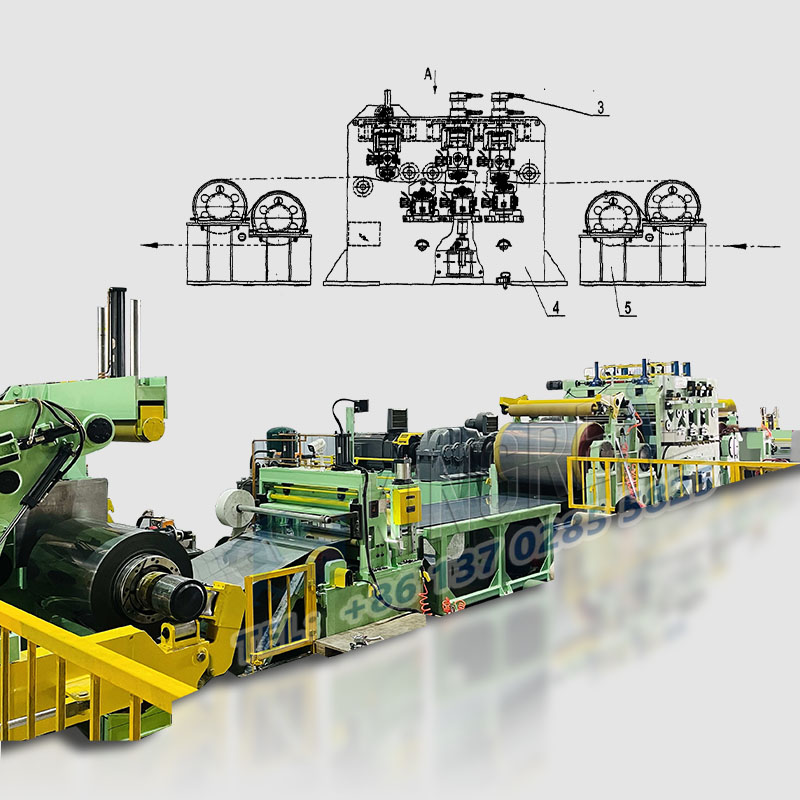

1, Fly Shearing Cut To Length Line: Due to the increasing demand for metal sheet products in large coil processing factories and the market, the cut-to-length line can provide customers with flying shear shearing devices to help customers achieve the production efficiency of continuous shearing without stopping during the metal coil shearing process. The production efficiency of the flying shear cut-to-length line can reach 80M/Min.

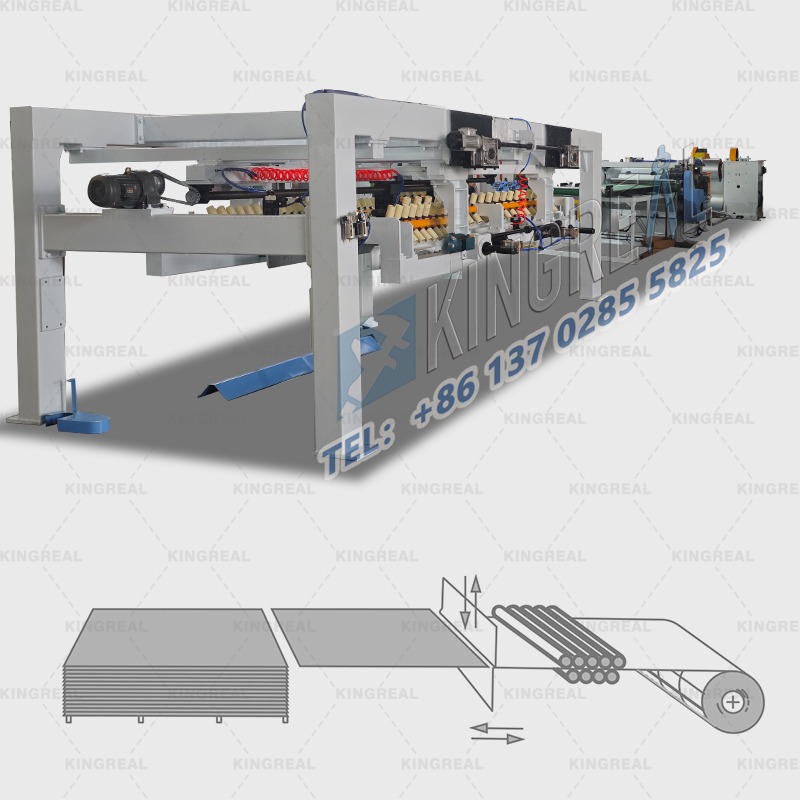

2, Rotary Shearing Cut To Length Line: The rotary shearing to length production line is dedicated to high-precision straightening and cutting to length of cold-rolled steel (CR), stainless steel (S.S), aluminum alloy (Al) and other material products. The core advantage of this equipment is that it adopts a continuous and uninterrupted shearing process to effectively eliminate the microscopic indentation defects caused by shearing during shutdown.