Video About HR Slitting Machine

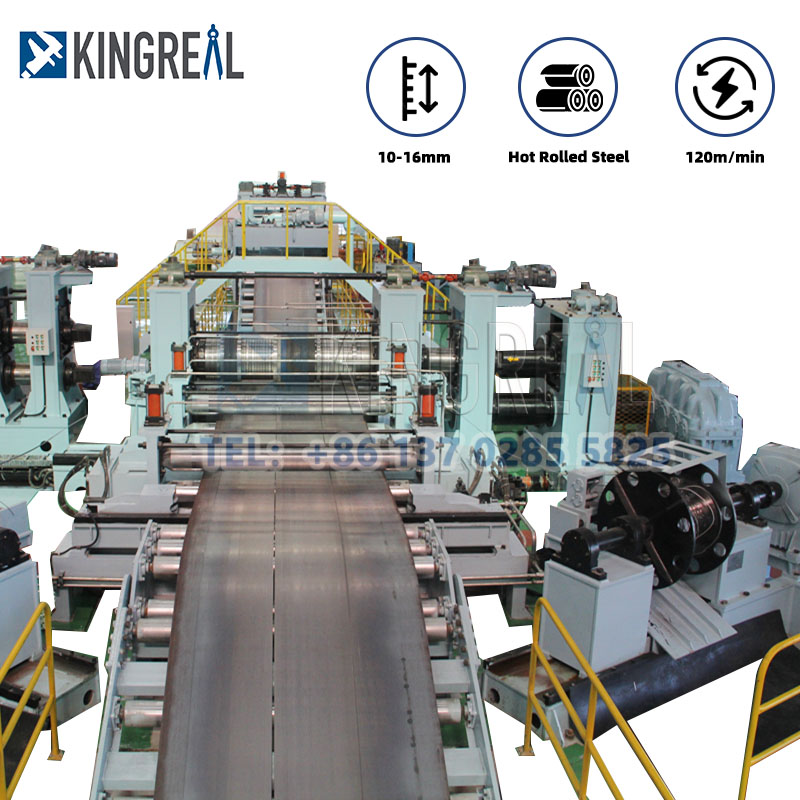

Description Of HR Slitting Machine

KINGREAL SLITTING stands as a leading provider of HR Slitting Machines, offering a comprehensive range designed to coil continuous cold and hot rolled steel as well as galvanized steel into strips of precise widths. These strips are then rewound into coils, catering to various industrial needs. Hot Rolling Coil Slitting Machines are crafted using premium raw materials, sourced from trusted market suppliers who meet rigorous international quality standards. This ensures that each machine we produce is robust, reliable, and capable of delivering consistent performance. The use of top-grade materials not only enhances the durability of our machines but also guarantees that they can handle high-intensity operations required in modern metal processing industries.

Hot rolled slitter machines are adept at processing a wide range of steel types, including both cold and hot rolled steel as well as galvanized steel. These machines are integral to the production of metal strips, which are crucial components in various sectors such as automotive, construction, electronics, and manufacturing. Our machines are available in multiple sizes to accommodate the diverse requirements of our clients, ensuring flexibility and adaptability to different production scales and specifications.

Understanding that each customer has unique needs, KINGREAL offers bespoke services tailored to the exact specifications provided by our clients. This customization capability allows for precise adjustments in machine configurations to match specific production demands, whether it's for unique strip widths, material types, or production volumes. Our commitment to precision ensures that every slitting machine operates at optimal efficiency, providing high-quality outputs that meet stringent industry standards.

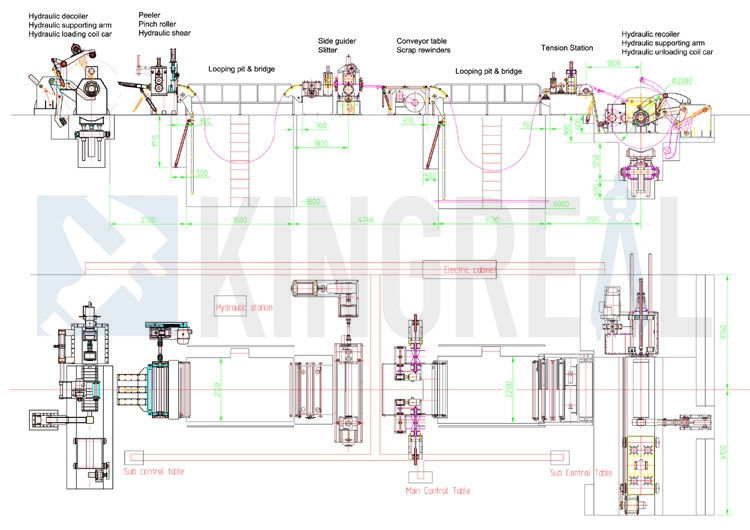

Working Process Of HR Slitting Machine

Upload material -- Decoiler Clip feed leveler/shearer -- First Loop bridge -- Guide and Slitting Scrap collection -- Second Loop bridge -- Recoiler -- Unload Coils

Component List:

No. | Name | Unit |

| 1 | Coil Load Trolley | 1 unit |

| 2 | Hydraulic Decoiler with Unwinding device | 1 set |

| 3 | Material shovel, Two rollers pinch, Hydraulic Shearing Machine | 1 set |

| 4 | #1 Loop Bridge | 1 unit |

| 5 | Main coil slitting machine | 1 set |

| 6 | Scrap collector | 1 set |

| 7 | #2Loop bridge | 1 set |

| 8 | Hydraulic tension station | 1 set |

| 9 | Uncoiler | 1 set |

| 10 | Unloading trolley | 1 unit |

Main Component Details

◇Coil Load Trolley

The loading trolley accurately transports heavy coils to the center of the unwinder. This feature ensures smooth and accurate positioning of the coil before it enters the subsequent processing steps, thus avoiding material waste and equipment failure due to improper positioning.

Various safety mechanisms, such as limit devices and emergency braking systems, ensure safe operation during transportation. These safety measures protect the operator and prevent production delays due to equipment failure.

Quantity | 1 set |

V-shaped surface | Nylon plate + steel plate welding |

Load-bearing | 15T |

Lifting stroke | 600mm |

Trolley power | motor |

Speef | 7m/min |

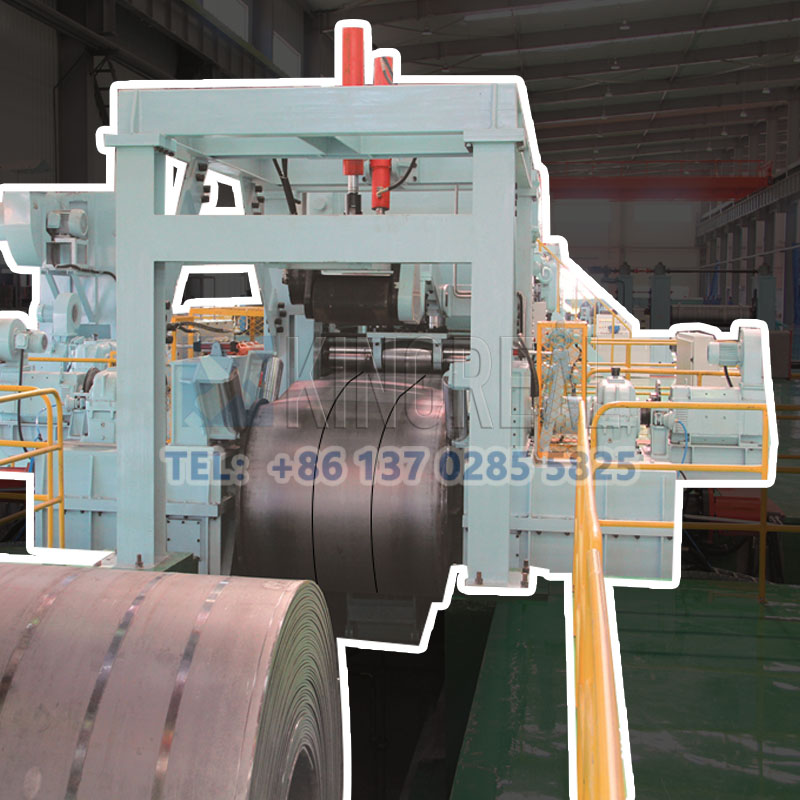

◇Hydraulic Decoiler

Hydraulic decoiler is a device used in slitting machines that opens and closes rolls by the action of hydraulic pressure. In slitting machines, hydraulic decoilers are mainly used to control the winding and releasing of paper or other materials to ensure a smooth and efficient slitting process.

Hydraulic decoiler work by utilizing the pressure of hydraulic fluid to actuate a piston or hydraulic cylinder that opens and closes the web. This mechanism provides great power and precise control, making the slitter more stable and reliable in handling a wide range of materials.

| Quantity | 1 set |

Load-bearing | 15T |

Steel coil inner diameter | Φ508mm |

Steel coil outer diameter | MAX: Φ1800mm |

Unwinding arc plate structure | Cantilever type, four-piece curved plate structure |

Expansion and contraction range of arc plate | Φ470mm-Φ508mm |

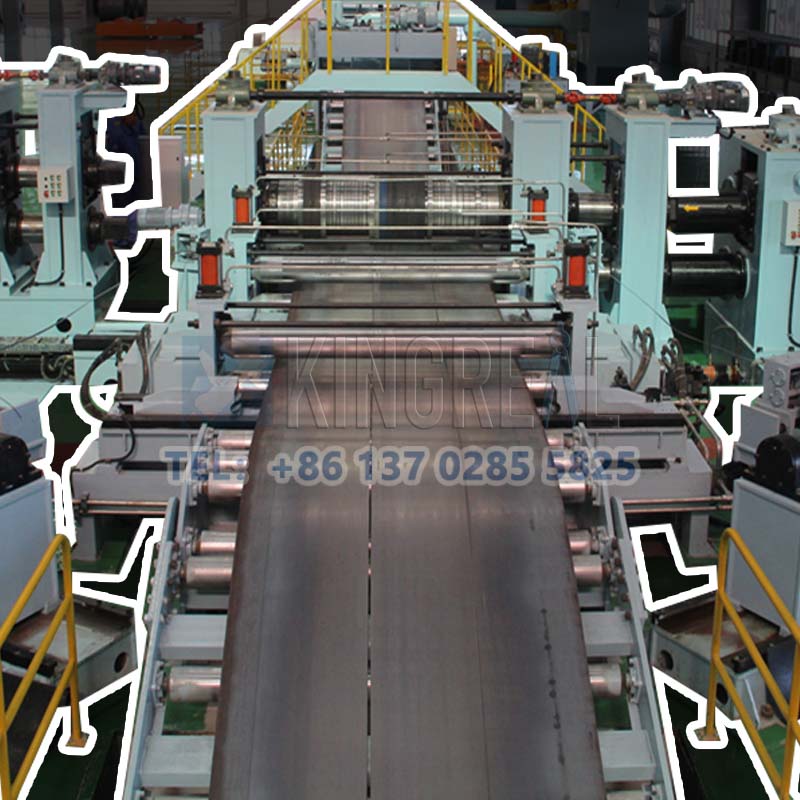

◇Main slitting machine

The slitting machine is designed to longitudinally cut coils into varying widths. By swapping out the combined spacers, the width of the resulting strips can be adjusted with flexibility. The cutter shaft’s positioning is maintained by the lower shaft, while the upper shaft’s distance is modified using a worm gear mechanism. This allows for synchronous adjustment and precise control of the gap between the upper and lower shafts. Both shafts are secured axially with nuts, and protective sleeves are installed at their ends to facilitate the mounting of the cutting blades.

Quantity | One set |

Slitting speed | 120m/min |

Tool shaft diameter | Φ160mm×1600mm |

Material | 42CrMo |

◇Scrap collection device

In slitting machine equipment, a scrap collection device is a system for automatically collecting and disposing of scrap and trim produced during the slitting process. It is a system for automatically collecting and disposing of scrap and trimmings generated during the slitting process. The scrap generated during the cutting process is guided to the collection position by means of a guiding device, which prevents the scrap from being scattered and keeps the working area neat and tidy.

Quantity | One left and one side feeder; can be used independently |

Rewinding scrap width | 2-10mm per side |

Winding speed | 0-120m/min |

Coil weight | MAX:500Kg |

Main motor power | AC4Kw(two sets) |

◇Rewinding Machine

In a slitter line, a winder is a device used to rewind slit narrow strips of metal strip into coils. The winder keeps the tension of the metal strip constant by means of a tension control system. Controlling the tension and speed of the coil ensures that the coil is tight and flat without curling or loosening.

Quantity | 1 set |

Load-bearing | 15T |

Steel coil inner diameter | Φ508mm |

Spindle material | 42CrMo |

Features of Hot-roll Slitting Line:

1. High slitting quality

The slitting quality of the hot rolled metal slitting machine is very high, maintaining small burrs and smooth cuts. This is very important for subsequent processing and use.

2. Easy to operate

Hot roll metal slitting machines are relatively simple to operate and require no complex setup or adjustments. Operators can get up and running quickly.

3. Adjustable slitting speed

The slitting speed of the hot coil metal slitting machine can be adjusted to adapt to different materials and production needs. This makes the production process more flexible.

Application of Hot Rolled Steel

Hot rolled steel is ductile at high temperatures and can be rolled into various shapes. It is a basic carbon steel product primarily used in applications where dimensional tolerances and surface finish quality are not critical.

Hot rolled steel plate provides performance, high strength and value at a competitive price. It is widely used in the following aspects:

- House clamp

- Coupling

- Deep drawing parts

- Washers

- Car parts

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil