Silicon Steel Coil Slitting Machine

KINGREAL SLITTING is one of the processional coil processing equipment manufacturer from China, can supply the whole solution for the coil slitting machine. Silicon steel coil slitting machine is a key equipment specially designed by KINGREAL SLITTING for processing silicon steel sheets. Silicon steel slitting machine can help the transformer industry, motor and home appliance industry and new energy industry to complete the processing technology of precision slitting and winding of silicon steel coils.

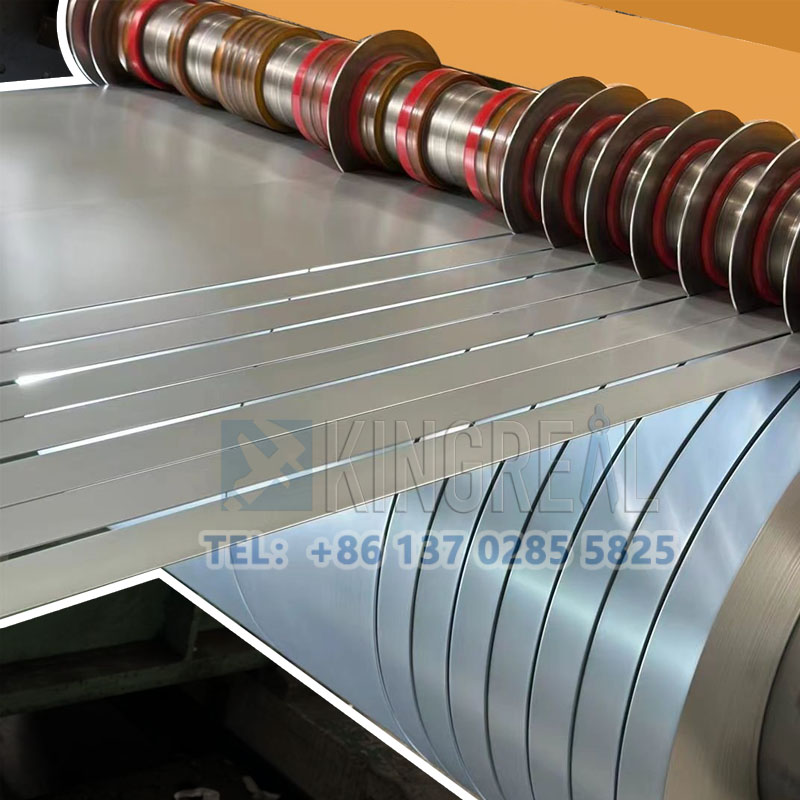

KINGREAL SLITTING silicon steel slitting machine can achieve high-precision slitting of silicon steel coil width tolerance ±0.1mm through adjustable knife disc system and automatic control. Silicon steel coils after secondary processing are the core materials for manufacturing transformer cores and motor stators/rotors.

Silicon steel slitting machine is usually linked by decoiler, leveling machine, slitting knife seat, waste winding, belt tension and winding machine to form a continuous production line. The slitting speed can reach 100-200M/Min. In order to ensure the processing quality of silicon steel coils, KINGREAL SLITTING adopts tension control system and looper device to avoid strip slipping or necking during shearing process, and ensure that the edge of the strip is straight after slitting of silicon steel coils.

What Is CRGO / CRNGO Silicon Steel Coil Slitting Machine

“Generally speaking, silicon steel coils are divided into CRGO silicon steel coil and CRNGO silicon steel according to the grain arrangement direction and application field. CRGO is mainly used for transformer cores such as power transformers and pulse transformers, and CRNGO is suitable for motor and electrical cores such as household appliances and new energy vehicle drive motors.

The properties of silicon steel need to be considered in the design process of silicon steel slitting machines. According to the different raw material properties of CRGO silicon steel coil and CRNGO silicon steel, there will be differences in the tolerance of slitting accuracy, the selection of slitting tool raw materials, and slitting speed.”

| Silicon Steel Slitting Machine Type | Coil Slitting Accuracy | Coil Slitting Machine Configuratio |

CRGO Silicon Steel Slitting Line | The width tolerance of oriented silicon steel strips usually needs to be controlled within ±0.1mm to ensure the high efficiency of transformer core laminations. Therefore, the silicon slitting machine needs to use high-hardness blades (such as Cr12MoV material) to reduce burrs (burrs are required to be ≤0.02mm) | The oriented silicon steel stripping equipment needs to be integrated with the EPC automatic deviation correction system to prevent the strip from running off and affecting the directional consistency. The silicon steel coil stripping requires a lower and more stable tension to avoid damage to the grain structure. |

CRNGO Silicon Steel Coil Slitting Line | Non-oriented silicon steel allows a slightly wider tolerance (such as ±0.2mm), which is suitable for scenes with lower dimensional tolerance requirements such as motor stators and rotors. Non-oriented silicon steel has a slightly higher tolerance for burrs. The silicon steel slitting machine can use ordinary alloy cutters | The deviation correction requirements in the non-oriented silicon steel stripping process are relatively loose, and there is no higher tension range allowed to improve processing efficiency. |

Main Components Of The Silicon Steel Coil Slitting Line

No. | Item | Qty |

| 1 | Coil-loading trolley | 1 set |

| 2 | Cantilever Decoiler + Coil Supporting Arm | 1 set |

| 3 | 1st Loop bridge | 1 set |

| 4 | Side guiding and correcting machine | 1 set |

| 5 | Main slitting machine (Disc type) | 1 set |

| 6 | Coil-edge scraps coiling machine (Vertical type) | 1 set |

| 7 | 2nd Loop bridge | 1 set |

| 8 | Tension Device | 1 set |

| 9 | Hydraulic Re-coiler with separating frame | 1 set |

| 10 | Coil-discharging trolley | 1 set |

| 11 | Coil-supporting arm for Recoiler | 1 set |

| 12 | Hydraulic system | 1 set |

| 13 | Pneumatic system | 1 set |

Technical Specification Of CRGO Silicon Steel Coil Slitting Machine

No. | Item | Technical Parameters |

| 1 | Material | CRGO, CRNGO |

| 2 | Thickness | 0.2-0.6mm |

| 3 | Material width | 300-1250mm |

| 4 | Max weight of coil | 15T |

| 5 | Production speed | (Material thickness 0.2-0.6mm): 0-200m/min (stepless speed regulation) |

| 6 | Threading speed | 0-15m/min |

| 7 | Power supply | 415V/50Hz/3Phases |

| 8 | Installed capacity | About 230KW |

Main Component Details Of Silicon Coil Slitting Line

1/Cantilever Decoiler For Silicon Steel Slitting Line The decoiler of a silicon steel slitting machine is one of the core components of a slitting and processing line, mainly used to unwind silicon steel coils and transport them stably to the subsequent slitting process. The decoiler hydraulically or mechanically fixes the silicon steel coil and releases the material by rotating it to ensure a smooth unwinding of the strip in the rolling direction and to avoid magnetic property degradation due to grain orientation misalignment.

The Silicon Steel Slitter decoiler is integrated with an EPC system, which detects strip deflection through sensors and adjusts the position of the decoiler to ensure that the slitting direction is consistent with the grain orientation of the silicon steel, to meet the high-precision requirements of transformer core lamination.

Load-bearing capacity 15T Inner diameter of steel coil φ508mm Outer diameter of steel coil MAX: Φ1800mm Tension generation Disc brake generates tension Unwinding power AC15Kw motor |  |

2/Side-Guiding Device And Pinch Feeding Machines

CRGO silicon steel coil slitting line side-guiding device and Pinch feeding machines is the core component for accurate positioning and stable material transportation in slitting lines. Side-Guiding Device Automatically adjusts the transverse position of the strip by monitoring the edge position of the silicon steel strip in real time to ensure that the slitting direction is consistent with the grain orientation, avoiding magnetic property degradation or slitting width overshoots due to deviation.

Pinch Feeding Machines provides constant tension by pinching the silicon steel strip with the upper and lower rollers, preventing material slippage or necking, and safeguarding the The slitting speed and slitting width of silicon steel coil are consistent.

Panel width Max 1250mm Width adjustment method Adjustable left and right by hand wheel Vertical roller material GCr15 steel Clamping roller Φ140mm×1300mm, with motor feeding |  |

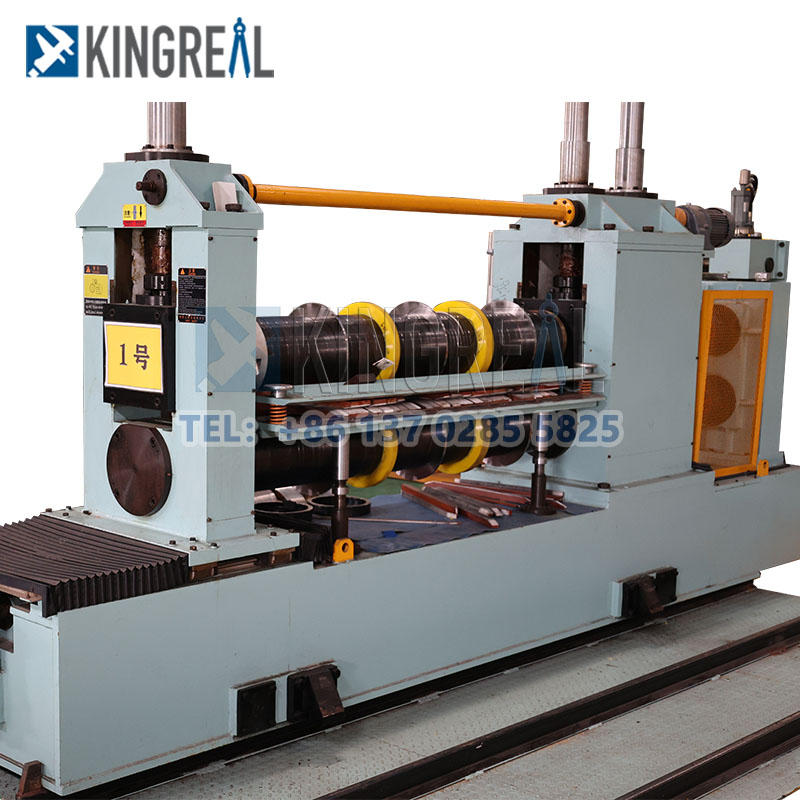

3/Main Coil Slitting Machine The main slitting knife holder device of silicon steel slitting machine is the core component of slitting processing, and its design directly affects the accuracy, efficiency and material utilization of silicon steel coil slitting. The main slitting knife holder device of silicon steel slitting machine solves the problems of precision, efficiency and material damage in the slitting of silicon steel sheet through high rigidity structure design, precision adjustment system and elastic buffer technology.

Silicon steel slitting machine knife seat on both sides of the set of guide shaft and support springs, through the spring elastic contact with the second and third bar seat, to absorb the impact of the shear process, to avoid deformation of the material. At the same time, it is equipped with buffer components to regulate the shearing pressure, which is suitable for processing silicon steel sheets of different thicknesses.

Slitting speed 200m/min Cutter shaft diameter Φ140mm×1300mm Material 42CrMo Main motor power AC75Kw motor Mobile arch motor Installed outside the frame does not affect the knife installation |  |

4/Separator and Tension Device

Separator and Tension Device are the core component to ensure silicon steel slitting accuracy and material stability, and its design needs to combine the brittleness and magnetic anisotropy of silicon steel material with the demand for high-precision slitting. The slit silicon steel strips are separated from each other by means of guide rollers, guide plates or staggered shear wheels to avoid entanglement or friction and to ensure a neat winding.

Silicon steel slitting and rewinding requires a closed loop tension control system with disc brakes or pneumatic adjustment to maintain constant tension during unwinding, slitting and rewinding to prevent wavy edges, slippage or necking.

The Separator of a silicon steel slitter guarantees the neatness and surface quality of the slit strips through physical separation and guided guiding, while the Tension Device relies on closed-loop control and dynamic adjustment to solve the problem of material transportation stability.

Spacer size Φ100×Φ200*3 Spacer size Φ200×Φ160×7 Intermediate roller Vertical lift Press plate type The pressure plate is driven by a cylinder to achieve the ideal downward pressure tension |

|

5/Hydraulic Rewind For The Silicon Coil Slitting Line

The winder of the silicon steel slitting machine is the core equipment at the end of the slitting processing line, which is used to rewind the slit silicon steel narrow strip into coils and ensure the neatness, tension stability and surface quality of the coils.

Silicon steel slitting and rewinding device through the servo motor-driven or pneumatically adjusted closed-loop tension system to maintain constant tension in the winding process, to prevent the silicon steel sheet due to fluctuations in tension produced by the phenomenon of wavy edges or slippage. It adopts the hydraulic expansion and contraction reel or air expansion shaft to hold the silicon steel coil, the maximum diameter of the coil can reach Φ600-1700mm, the support base is fixed with the sleeve through the vertical plate, and some of the heavy-duty equipment is equipped with the height-adjustable telescopic rod to support the coil.

Load-bearing capacity 15T Inner diameter of steel coil Φ508mm Main shaft material 42CrMo Arcuate plate of reel 55# steel quenched and tempered, hard chrome plated surface Clip jaws Cylinder driven expansion and contraction Outer diameter of steel coil MAX: Φ1800mm Push plate Cylinder driven Brake system Disc brake brake Power of main motor AC110Kw motor |

|

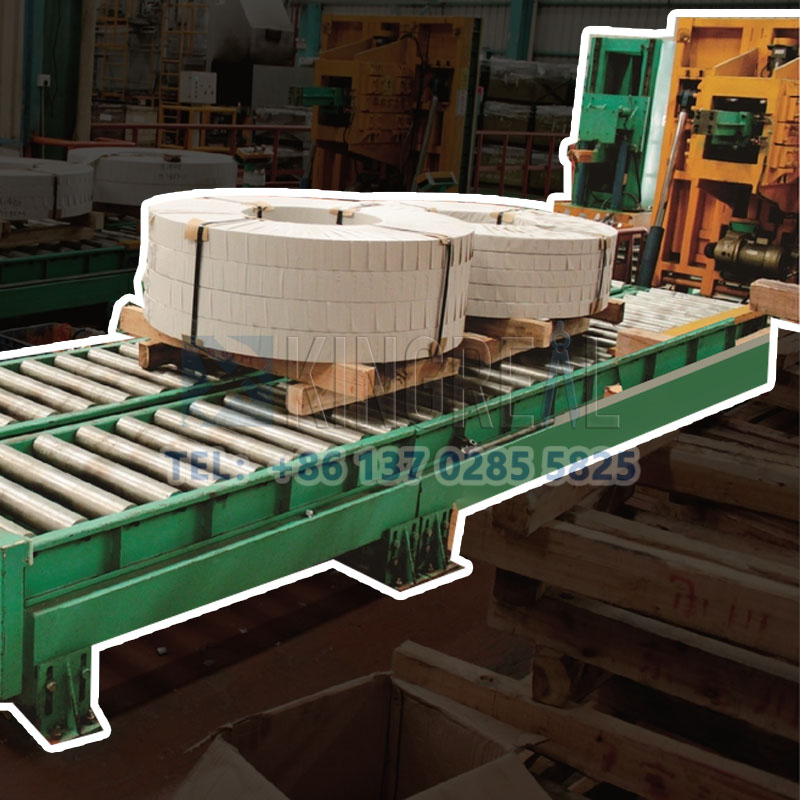

Optional Coil Packing Line For Silicon Coil Slitting Line

KINGREAL SLITTING can provide customers with fully automated coil baling lines to help coil processing factories realize automatic baling processes from coil processing to bundling and transporting after the completion of secondary processing, and to improve the productivity and precision of coil processing.

Fully automatic metal slitter baling line put into production application can help coil processing factories to improve market competitiveness, to obtain more long-term production benefits!

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil