Video Display For Steel Coil Slitting Line

Brief Introduce Of(0.3-3)×1600MM Steel Slitting Machine

Metal slitting machines can precisely cut wide metal coils into narrow strips of various widths by adjusting the blade sets, thereby meeting the diverse needs of customers. With the advancement of technology and the rising demand for customized products across various industries, the market demand for metal coils of different specifications is increasing. The most common coil widths in the market include 800mm, 1600mm, and 2000mm, among others. Recently, the (0.3-3) x 1600mm Steel Slitting Machine designed for these widths has become the most popular production line.

The (0.3-3)×1600MM Steel Slitting Machine, a light gauge steel slitting line, is specifically designed to handle steel coils with thicknesses ranging from 0.3 to 3mm and widths between 800 and 1600mm. This machine is capable of accurately slitting wide steel coils through processes including uncoiling, leveling, clamping, slitting, tension, and finally winding. It produces slit coils with specified widths and an error margin of less than 0.05mm.

Key Features and Capabilities:

Precision Slitting: The machine ensures precise slitting of metal coils into narrow strips with high accuracy, essential for various industrial applications.

Versatile Material Handling: It can process a variety of metal coils, including:

- Aluminum

- Galvanized Steel Coils

- Hot Rolled Coils

- Cold Rolled Coils

- Tinplate

- Copper Coils

- Silicon Steel

˙High Production Capacity: The steel slitting machine can accommodate up to 25 slits or even more, depending on the thickness of the raw material and the customer's specific requirements. This high capacity makes it suitable for large-scale steel processing plants.

˙Sequential Processing: By efficiently managing the uncoiling, leveling, clamping, slitting, tension, and winding processes, the machine ensures the production of high-quality slit coils ready for further processing or direct use. This steel slitting machine meets the diverse needs of the market, providing a reliable solution for steel processing plants to adapt to various metal coil specifications and maintain high precision and efficiency in their operations.

KINGREAL SLITTING supports all custom production and new demand challenges, continuously researching in the field of steel coil slitting machine design and manufacturing. They have increased the production speed of metal slitter to 200M/Min, allowing for the processing of small coils in just a few minutes, meeting the efficiency requirements of large-scale steel processing. Additionally, they offer a range of production speeds for coil slitting lines to further meet the diverse needs of various factories.

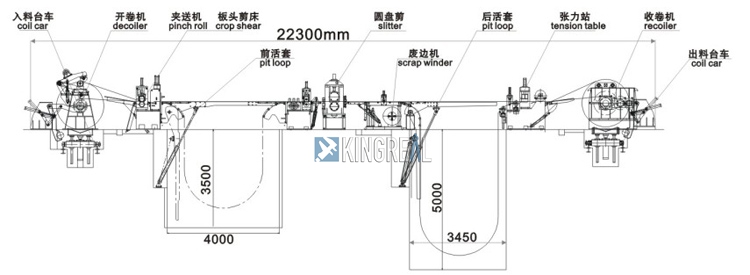

Working Process Of Steel Coil Slitting Machine

Trolley Loading Coil -- Hydraulic Decoiler -- Pinch Roller -- Leveler -- Plate Head Shears -- Loop Bridge -- Slitting Machine -- Tension Station -- Separating -- Rewinding Machine

Technical Specification Of Standard Coil Slitting Machine

| 1 | Raw material | CR |

| 2 | Thickness | 0.3-3.0mm |

| 3 | Width | 500-1600mm |

| 4 | Coil outer diameter | ≤Φ2000mm |

| 5 | Coil inner diameter | Φ508mm、Φ610mm(With rubber sleeve) |

| 6 | Coil weight | 25T |

| 7 | Slitting Speed | 0~200m/min (Stepless speed regulation) |

| 8 | Strip through speed | 0~15m/min |

| 9 | Power | 380V/50Hz/3Phase |

Coil Slitting Machine Components

1. Decoiler For Steel Slitting Line

The starting point in a coil slitting line, the decoiler unwinds the metal coil, ensuring a steady and controlled feed into the machine. Hydraulic vertical centering ensures the coil is perfectly aligned.

2. Pinch Roll and Lever Mechanism For Steel Slitter

This component grips the metal strip and guides it into the steel slitting machine. It maintains tension and alignment, preventing mis-feeder and ensuring smooth operation.

3. Leveling Device For Steel Slitter Machine

Ensures the metal strip is flat and free of imperfections before it reaches the slitting blades. This step is crucial for the accuracy and quality of the final product in a metal slitting machine.

4. Slitter Head For Steel Slitting Machin

The core of the metal slitting machine, the slitter head houses the blades that cut the metal coil into narrower strips. The precision and sharpness of these blades determine the quality and consistency of the slitting process.

5. Loop Bridge For Steel Slitter

Manages the slack created by the slitting process, preventing tension variations that could affect the quality of the cuts. This component is essential for maintaining the efficiency of a coil slitting line.

6. Tension Station For Steel Coil Slitter

Maintains consistent tension on the strips to ensure precise and uniform cuts. Proper tension is vital in a steel slitting machine to avoid stretching or damaging the metal strips.

7. Recoiler For Slitter Machine

Recoiler: The final step in the coil slitting line, the recoiler winds the cut strips into new coils, ready for further processing or shipment. This component ensures that the finished products are neatly packaged and easy to handle.

8. Waste Rewinding System For Steel Slitting Line

Waste Rewinding System: Collects and winds the scrap edges produced during slitting, keeping the workspace clean and reducing material waste.

Advantage Of KINGREAL SLITTING Coil Slitting Line

1. The primary step in the metal slitting machine production line involves precision slitting, which is achieved swiftly and accurately using a set of sharp circular knives. By adjusting the blade assembly, the width of the cut products can be flexibly changed. The knife shaft features a fixed lower shaft and an adjustable upper shaft, utilizing a worm gear system to synchronize the adjustment, ensuring precise control of the gap between the shafts. The upper and lower cutter shafts are secured axially with nuts and are equipped with tool protectors at the ends. For convenience in blade replacement, the main machine employs a motorized opening and closing seat frame.

2. The coil slitting machine offers a variety of optional configurations to meet diverse production needs. For example, in the coiling process, KINGREAL provides options such as loading trolleys and support arms. Customers can select between single or double knife holders based on different slitting output requirements, enhancing the flexibility and efficiency of the slitting process.

3. The coil slitting line is designed for ease of use, featuring a PLC control panel and monitoring system that simplifies the slitting operations. Operators will find it straightforward to manage the steel slitting line, thanks to its intuitive controls. Additionally, with the optional second blade platform, adjusting the slitting width on the coil slitting line becomes quicker and more efficient, further streamlining the production process.

FAQ: What can I get if I choose KINGREAL SLITTING Coil Slitting Line?

1. A very competitive pricing system, KINGREAL SLITTING can serve both large steel processing centers and small coil handling plants, offering a wide range of metal slitting machine solution options for differently positioned customers, from the configuration of the machine to the final price.

2. The slitting quality of Coil Slitting Line is effectively guaranteed, KINGREAL SLITTING has an independent processing plant and a complete quality control system, which requires strict measurement and control of slitting accuracy.

3. It is capable of handling multiple production requirements. (0.3-3)×1600MM Steel Slitting Machine is just one of the popular models of metal slitting machine, KINGREAL SLITTING can handle coils with thickness ranging from 0.2-20MM and width ranging from 500-2500MM, and the production speed is from 40M/Min-200M/Min.

With many years of experience in production and sales, KINGREAL SLITTING is definitely one of your best supplier choices!

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil