Video About Metal Cut To Length Lines

Description Of Metal Cut To Length Lines

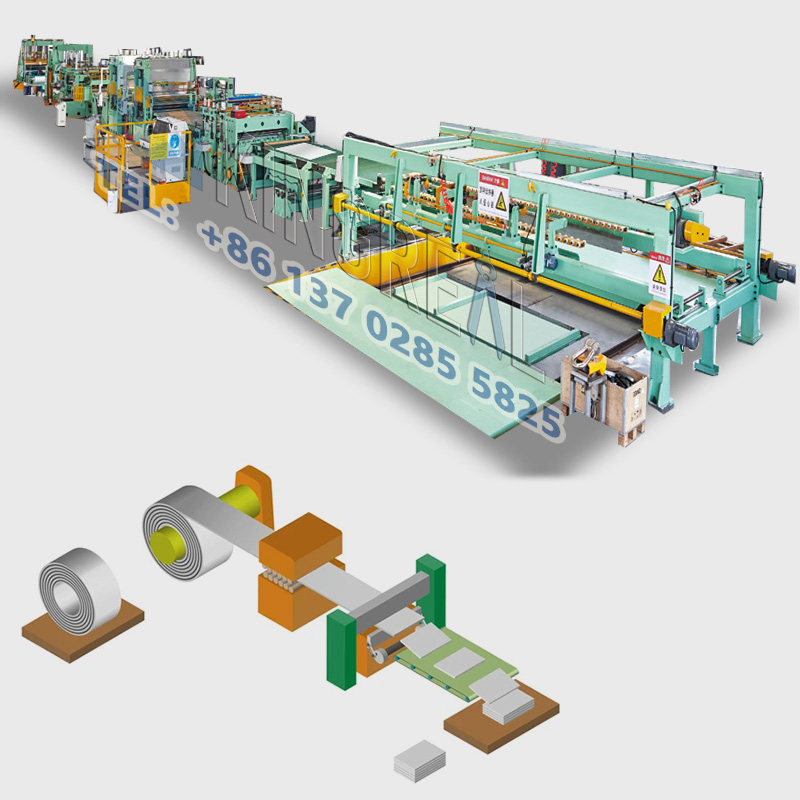

Metal cut to length lines, also known as cut-to-length line, is used for uncoiling, leveling and shearing metal coils into flat metal sheet of required length and stacking. KINGREAL SLITTING metal cut to length line is suitable for processing cold-rolled and hot-rolled steel coils, galvanized steel coils, silicon steel coils, stainless steel coils, aluminum coils, etc. into different widths and shearing according to the production requirements of users.

Cut to length line can meet the processing needs of different metal raw materials and is used for the procurement of sheet metal raw materials for industries such as automobile manufacturing, home appliance manufacturing, decorative materials and heavy industry. This cut to length machine processes the strip coil into the required billets through the processes of uncoiling, straightening and precision cutting. Metal cut to length machine mainly consists of uncoiler, clamp leveler, gauge, cutter, stacker, etc., and is equipped with auxiliary devices such as feeder, side guide device, transition device, conveyor, etc.

Standard Workflow Of Metal Cut To Length Line:

Decoiler with Trolly Car --- Hydraulic Decoiler ---Leveling---Loop Bridge --- Main Leveling Machine --- Encode & Measuring Device (with tail plate pinching) --- Cutting--- Conveyor --- Hydraulic Lift Platform --- Stacker with blower device --- unload cart

Reference Data Of Metal Cut To Length Line

Coil Width | 500-2000MM |

Coil Thickness | 0.3-3MM |

Coil Weight | up to 30Ton |

| Materials | Hot-rolled, Cold-rolled, PPGI, Silicon steel, Aluminum, Galvanized, Pre-painted |

Shaft Diameter | 110mm |

Machine frame | 350H steel welding |

| Material of rollers | Inside 45# steel outside Rubber |

| Drive motor power | 5.5kw |

| Leveling Rollers | up layer 5 rollers down layer 6 rollers |

Cut Power | Hydraulic power |

Main Component Details Of Cut To Length Line

1. Hydraulic coil-in cart for cut to length line

The trolley can be moved horizontally and vertically to facilitate putting the steel coils into the uncoiler.

It is driven vertically by a hydraulic cylinder with four guide pillars.

Horizontal movement is driven by an oscillating motor.

It can carry a capacity of 1 5 tons (maximum).

2 . Hydraulic cantilever uncoiler

Supports coils and performs uncoiling. Capacity is 15 tons (maximum).

Hydraulic cylinders are used to make the uncoiler retractable and suitable for the coil inside diameter. It is equipped with a cantilever arm.

The 10 0 N.m torque motor drives coil operation in forward and reverse directions, and can also unwind with tension.

The iron core can ensure the coil inner diameter extension range φ508.

Structure: Steel plate is welded to the profile.

3. 6-hour pre-flattening machine for cut to length machine

Straightening of rough boards and guides can be done immediately after entering the process

Mechanical structure: consists of two rows of leveling rollers, two rows of intermediate rollers, 2 groups of rollers, drive unit, 2 pinch feed rollers and frame. Both the end of each roll with drive roll pin bearings, 17 leveling rolls all main drive rolls small size, diameter 65, roll er distance is 70; 19 intermediate rolls, diameter 65; 2 pinch rolls ERS coated with upper surface polyurethane, which prevents sheet. Two groups of support rollers, in each group, each three and of small size.

The role of the intermediate roller is to balance the force on the leveling roller, reduce the friction on the roller, reduce the friction sheet, and ensure the high quality surface leveling effect.

The role of the support roller is to support the leveling roller. Adjustable individually to suit different types

The work rollers can be adjusted electrically is controlled by 2-hand gap wheelš to ensure the leveling quality.

Driving method: All independent rollers and gear box are driven by 55kw frequency conversion motor

Roll process: raw material - rough machining - hardened HRC55-60 - fine grinding - hard chrome plating Automatic lubrication system

4. Loop For Metal Cut To Length Machine

It uses 2 sets of eyes to control the speed buffer between the uncoiler and the slitter.

T-eyes are controlled by PLC.

Function: It is used to eliminate the different speed and bring the wrong tracked sheet back to the right direction.

At first, the pallets and transition plates are jacked up by cylinders to make the head pass. When working, the transition plate and pallets move down and the plates are stored in the pit.

5. Side guide device

Vertical rollers on both sides are used to guide the strip into the straightening device and the cutting machine.

The vertical rollers on both sides are adjusted by screws. The width range is 500-1500mm.

6. Servo precision straightening machine

Controlled by servo motor for high speed feed and precise length control adjustment.

Operation is carried out on the control console with programmable control.

Drive method: 15KW servo motor, precision reduction drive, synchronized conveyor belt to feed rollers

7. High-speed cutting machine for cut to length line

Shearing mode: hydraulic up and down shear, with the feeder direct signal automatic shear

The use of gap adjustment design cutting materials, heat treatment can safely shear 2mm steel plate

8. Transport table

Transport belt anti-slip and wear-resistant

Drive: with line speed and by sending 4 KW frequency control motor

9. Hydraulic lifting table

Plate length range from 500- 6000mm (customizable)

Cab width ranges from 500 to 1600mm

10. Pneumatic stacker device

Pneumatic stacking of plates, PLC controlled lifting.

Three 0.75kw motors dragging to adjust the width and length.

It is equipped with matching said wind device trumpet With high pressure fan to prevent friction of paper.

11. Exit coil car

Set horizontal unloading car to neatly code the table output line to ensure the continuity of sheet metal production.

Set the output power of cycloidal gear motor.

12. Pneumatic system

Pneumatic system consists of gas source (provided by the demander), gas source processing components, Salennoid, related pipelines and cylinders, etc. Salennoid and other components are made of high quality products.

Technical parameters: Air source pressure: 0.4-0.6Mpa. capacity: 1m³/min.

13. Hydraulic system

Make sure that each hydraulic component is used.

The working pressure of the hydraulic system is 6.3-16Mpa.

14. Electrical system

Adopt frequency conversion motor control method and PLC control method, LCD screen control, code fixed length cutting, automatic counting.

Feature of Metal Cut-To-Length Line

-High output/throughput and flow through strict tool time minimization and high production speed

-Excellent sheet flatness through the use of ""four-high"" and ""six-high"" straighteners

-Elimination of edge waviness and center snap marks by using a row of back-up rollers on the leveler

-Accurate cutting accuracy and sheet angles

-Low burr by cutting with edge trimmers and cut-to-length shears

-High stacking accuracy by using a separate stacking system

-Gentle handling of highly sensitive surfaces, e.g. in the automotive industry, through special transport and stacking methods

-Material strengths in excess of 1,400 N/mm² and yield strengths up to 1,000 N/mm²

FAQ: How can I know the design and proposal of the machine line?

Generally speaking, we need to know:

(1) Machine type: slitting line or cut to length line (normal CTL or flying CTL).

(2) Raw material info: such as thickness/width/master coil weight/coil ID/coil OD.

(3) Final product info: such as slit no’s (at thinnest and thickest)/min. strip width/precision and tolerance/exit coil ID, etc.

such as target length to cut, length tolerance, diagonal tolerance, etc.

4)Line speed: normal type or high speed type

5)Line type: normal type or compact design (for example, same function with single loop or double loops)

6)Electrical system: China mainland/Taiwan/Japan/European brands

7)Optional functions: such as paper collector/film coating/burr masher/digital display/special loading and unloading designs, etc.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil