Video About Stainless Steel Cut To Length Machine

Overview Of Stainless Steel Cut To Length Machine

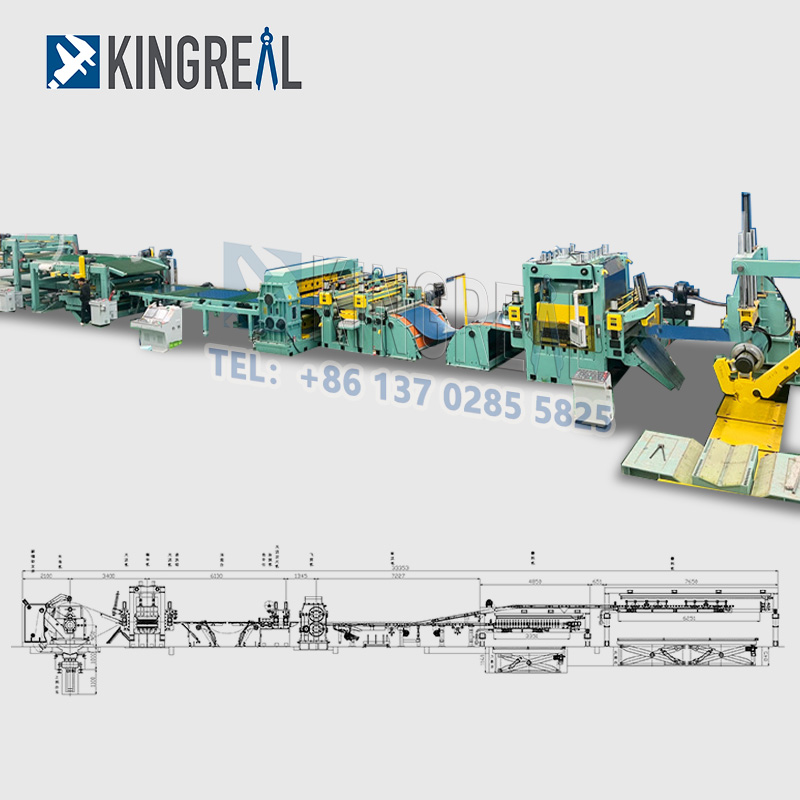

KINGREAL SLITTING is a leading supplier of constant length (CTL) production lines and steel products. KINGREAL SLITTING CTL lines, including the stainless steel cut to length line, process bundles of steel coils through a precise sequence of flattening, leveling, and cross-cutting. KINGREAL SLITTING carefully studies each case to develop customized solutions. Depending on the customer's needs, the CTL lines incorporate different types of shears, such as start-stop shears, flying shears, and rotary shears. This tailored approach ensures that each stainless steel cut to length machine meets specific production requirements.

In addition to the shearing options, KINGREAL SLITTING provides the most convenient machines for different applications, including high-precision straighteners and stack. Edge trimming can be integrated into the process. The entire line is centrally controlled by a numerical control (NC) system, offering three major advantages:

1. High Automation: Reduces manual intervention, streamlining operations.

2. High Productivity: Enhances output efficiency, meeting large-scale production demands.

3. High Working Accuracy: Ensures precise cuts and consistent quality.

KINGREAL SLITTING CTL lines, including the stainless steel cut to length line, are designed for versatile and efficient operation. They can uncoil, feed, level, edge trim, size, slit, cross-cut, and stack in a single loading sequence. This comprehensive processing capability significantly reduces worker labor intensity and allows for step-less speed adjustment to match user requirements. The cross-cutting line is particularly effective for uncoiling and cutting steel coils to specified lengths after flattening them in a start-stop manner, ensuring high-quality and accurately sized products. KINGREAL SLITTING stainless steel cut to length line and stainless steel cut to length machine represent advanced technological solutions for precise and efficient metal processing. With customized designs and high automation, we ensure our clients receive the most effective and reliable equipment for their production needs.

Working Process Of Steel Cut To Length Line

Uncoiler → shovel device → flattening → accumulator → centering device → fixed length feeding device → cutting machine → conveying table → precision straightening machine → feeding rollers → stacking frame

Main Component List

No. | Name | Qty |

| 1 | Raw Material Table | 1 Unit |

| 2 | Trolley for Feeding | 1 Unit |

| 3 | Front Auxiliary Support | 1 Unit |

| 4 | Uncoiler + Unwinding Device | 1 Set |

| 5 | Leveler Machine | 1 Unit |

| 6 | Upper side Film Lamination Machine | 1 Unit |

| 7 | Short Looper | 1 Unit |

| 8 | Sides Guiding Device | 1 Unit |

| 9 | Pinch NC Length Measure | 1 Unit |

| 10 | Fly Shearing Machine | 1 Unit |

| 11 | Conveying Machine | 1 Unit |

| 12 | Product Stacking Machine | 1 Unit |

| 13 | Discharging Table | 1 Set |

| 14 | Hydraulic System | 1 Unit |

| 15 | Pneumatic System | 1 Set |

| 16 | Electrical System | 1 Set |

Details Of Component

1. Uncoiler For Cut To Length

Loading capacity : 5T

Inner diameter: 470-530mm

Steel coil width: 914, 1000, 1220, 1250 mm.

Working speed: 0-15m/min, adjustable

According to your actual drawing.

2. Feeding Table For Cut ToLength Line

It is used to control the width and position of the steel sheet.

The sheet is guided into the machine with correct position,

to make sure the panel is neat and parallel.

3. Main Frame For Cut To Length

Material 350 H steel

Feature more table, no shaking

4. Forming Rollers For Cut To Length Line

Material High grade 45# steel.

Roller stations 3-6 stations. According to your actual drawing.

5. Cutting System For Cut To Length

Material of blade Cr12MOV, much better than normal Cr12 material

Hydraulic power 3KW

6. Control Cabinet

Suitable power 380V, 50Hz, 3phase or according to your need.

Feature The whole process is automatically controlled by the computer. In this way, you can ensure the accuracy and easy work.

Performance Characteristics Of Steel Cut To Length Machine

The whole cut to length machine is designed with reasonable structure, compact shape, high precision, high efficiency, flexible and convenient adjustment.

Functions: automatic detection of steel coil parameters, one key to coil, one key to take material, automatic alignment adjustment. Automatic switching of double palletizers, automatic detection and tapping, precise calculation, safety and reliability.

The manufacturing process of the whole CTL Line machine is strictly in accordance with the standard specification of machinery, and the production of each component is tracked and controlled. Cooperation with famous manufacturers at home and abroad has introduced the first-class leveling line technology, which is developed and extended by the professional technical team on this basis to provide users with high quality and efficient automatic sheet processing equipment. The bearings and slides of the main machine are imported brands, with advanced lubrication system, long service life. The electrical components are imported high-end brands, and the mechanical supporting parts are famous brands at home and abroad.

● Higher cutting accuracy

● Improved reliability

● Scheduled production

● Flexible machining options

● High-resolution graphic monitor for plant floor human-machine interface (MM) message processing and display

● Programmable function keys for specific tasks

● Cutting function can be selected in automatic or manual mode, and in automatic mode the system can operate in single step or continuous operation

● Keying mode for setting: cutting length, quantity, work number, parameter adjustment... Through nema type front panel

● The operator can select the special screen/menu named: job number, cutting length, quantity, parameter setting operation parameters

FAQ: How To Turn On The Cut To Length Line?

1. The first is to turn on the power, turn on the key switch on the control panel, and then press the oil pump to start, so you will hear the sound of the oil pump rotation.

2. Shear plate material must be noted is the gap adjustment, generally located on the side of the machine, according to the plate material 12% ~ 15% adjustment gap, the gap value can be read in the dial.

3. The backstop material adjustment are generally electric quick adjustment and manual fine adjustment, you can first use electric adjustment is the approximate size in the manual fine adjustment to your desired shear position.

4. Step on the foot switch until the plate material cut section in the release, otherwise the release will automatically lift in the middle.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil