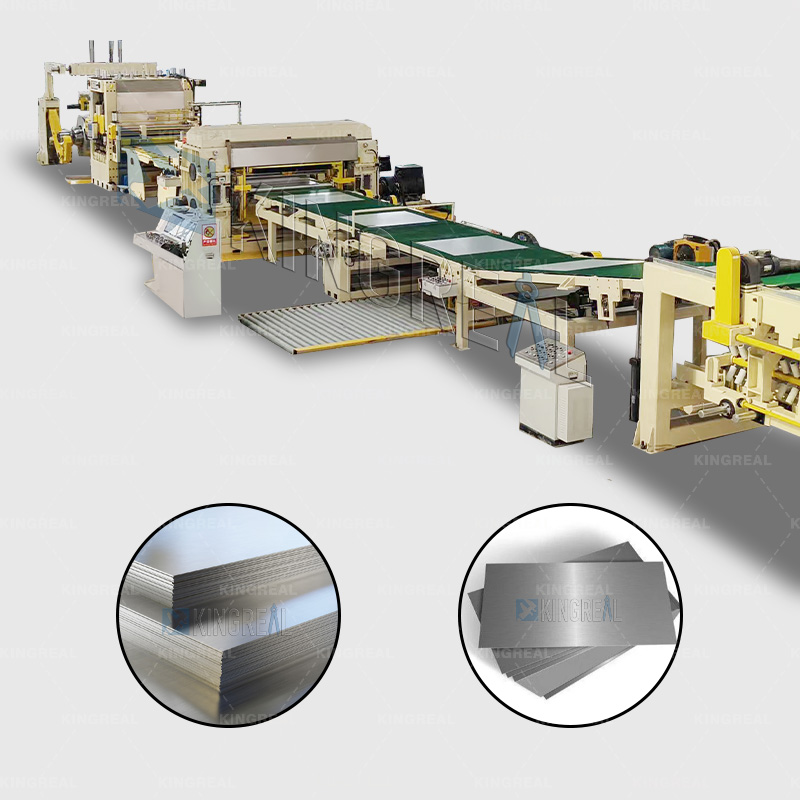

What are Coil Cut to Length Lines?

Coil cut to length lines are used to process coiled metal materials into precisely cut sheets. These coil cut to length machines typically consist of multiple components, including a feeding machine, straightening machine, shearing machine, and stacking solution. Whether for resale or further processing, coil cut to length lines offer high precision and improved production efficiency.

KINGREAL SLITTING coil cut to length machines can handle materials with thicknesses ranging from 0.2mm to 25mm, suitable for general processors, original equipment manufacturers, and stamping manufacturers. KINGREAL SLITTING coil cut to length lines can be customized to meet specific customer needs. Furthermore, KINGREAL SLITTING coil cut to length machines meet multiple industry standard length tolerances, such as ASTM, ANSI, AISI, EN, JIS, and API, ensuring customers receive the best product quality and service.

Coil Cut to Length Lines Parameters

Model | Processing Plate Thickness (mm) | Processing Plate Width (mm) | Cutting Accuracy (mm) | Maximum Cutting Speed (m/min) | Maximum Cutting Frequency (spm) | Uncoiling Weight (ton) | Remarks |

Model 1 | 0.3-2.0 | 100-800 | ±0.3 | 70 | 100 | 7 | Cutting speed and accuracy are based on a 2m cut length; cutting frequency is based on a 300mm cut length. Technical parameters and equipment configuration can be determined according to customer needs. |

Model 2 | 0.2-2.0 | 900-1800 | ±0.3 | 50 | 40 | 20 | |

Model 3 | 0.5-3 | 900-2000 | ±0.3 | 45 | 40 | 30 | |

Model 4 | 1-6 | 900-2000 | ±1 | 25 | 20 | 30 | |

Model 5 | 2-8 | 900-2000 | ±1 | 20 | 20 | 30 | |

Model 6 | 3-12 | 900-2000 | ±1.5 | 20 | 10 | 30 | |

Model 7 | 4-16 | 900-2000 | ±2 | 15 | 8 | 30 |

Coil Cut to Length Machine Solutions

Based on customers' required metal cutting capabilities, types of raw materials processed, and budget differences, KINGREAL SLITTING is committed to providing customers with different coil cut to length lines solutions. These solutions are designed to meet the specific needs of customers' actual projects, ensuring efficient and smooth production processes.

Types of coil cut to length machine by application

KINGREAL SLITTING coil cut to length lines adapt to various market demands, with working thickness ranges from 0.2mm to 25mm. Different speed ranges of coil cut to length machines ensure optimal performance for specific industries or applications. For example, high-speed coil cut to length lines use rotary shearing or fly shearing for faster production efficiency, while lower-speed coil cut to length machines use hydraulic shears or eccentric shears to meet the needs of different customers.

-Light gauge cut to length machine

Light gauge cut to length lines are designed for processing materials with thicknesses from 0.2mm to 3mm. Due to their low power consumption, they are more economical than other medium duty cut to length machines for processing thin materials. They are particularly suitable for small-scale processing enterprises, effectively reducing production costs.

-Medium gauge cut to length line

For coils with thicknesses between 0.3mm and 6mm, medium duty cut to length lines are an ideal choice. This coil cut to length line can handle common sheet metal thicknesses on the market and is widely used in various industries, such as automotive manufacturing and construction engineering. Through optimized design and efficient operating modes, medium duty cut to length lines can significantly improve production efficiency.

-Heavy gauge cut to length line

Designed specifically for processing sheet metal thicker than 6mm, heavy gauge cut to length lines offer cutting capabilities up to 25mm. These coil cut to length machines are suitable for demanding applications in heavy industry, shipbuilding, and construction. KINGREAL SLITTING heavy gauge cut to length lines not only possess powerful cutting capabilities but also achieve high-precision cutting, ensuring the excellent quality of the final product.

-Compact cut to length line

For production facilities with limited space, KINGREAL SLITTING compact cut to length line solution is undoubtedly the best choice. It is not only cost-effective but also suitable for small-batch production. Despite its small footprint, the compact cut to length line is equipped with all the necessary functions of a standard coil cut to length machine, allowing it to flexibly meet the production needs of different customers.

-Rotary shearing cut to length line

With the help of rotary shearing or fly shearing technology, KINGREAL SLITTING rotary shearing cut to length lines achieve excellent production capacity. This

coil cut to length lines not only ensures high precision during the cutting process but also reaches an operating speed of 80m/min. Combined with the advantages of a high-precision leveling machine, this coil cut to length machine has excellent leveling capabilities for the processed material surface, providing strong assurance for subsequent cutting accuracy.

Advantages of Coil Cut to Length Lines

Easy operation

KINGREAL SLITTING coil cut to length machines are equipped with advanced PLC control panels, making operation very convenient. The operator only needs to input production parameters on the panel, including output, speed, and sheet specifications, and the coil cut to length lines will operate automatically. Even with only one operator, the entire coil cut to length machine can be easily operated, significantly reducing the complexity of production management.

Flexible coil cut to length lines solutions

KINGREAL SLITTING designs a variety of coil cut to length machine solutions based on customers' specific production needs, covering different cutting lengths, working ranges, and price ranges. KINGREAL SLITTING can provide various cutting methods, including fly shearing, rotary shearing, swing shearing, and fixed shearing. In addition, customers can customize coil cut to length lines components according to their actual needs, such as adding a leveling machine, laminating device, or stacking table, to ensure a fast and accurate production process.

Multiple speed options for coil cut to length lines

KINGREAL SLITTING can provide customers with coil cut to length machine solutions with different cutting speeds. Coil cut to length lines with different speeds are equipped with different component parameters and performance specifications, designed to meet customers' different requirements for speed and efficiency.

FAQ About Coil Cut to Length Lines

Q1: What is coil cut to length machine in manufacturing?

A1: Coil cut to length lines are used to cut metal coils to specific lengths. The resulting metal sheets are often used to manufacture structural components or casings for industrial transformers, panels, brackets, and other applications.

Q2: How does a coil cut to length machine work in metal processing?

A2: A coil cut to length machine completes the entire process from uncoiling and leveling metal coils to cutting them to specific lengths and stacking the sheets, using four core components: a decoiler, a leveler, a shear, and a stacker. This systematic process ensures efficient production and high quality of metal sheets.

Q3: What is the difference between cutting and slitting?

A3: Slitting refers to dividing a wide coil into narrower strips along its length, usually done by a coil slitting machine. Cutting, on the other hand, involves dividing the material into separate pieces, which is done by coil cut to length lines.

Q4: What materials can coil cut to length lines cut?

A4: KINGREAL SLITTING coil cut to length lines can process various metal materials, including aluminum, iron, steel, stainless steel, copper, and cold-rolled and hot-rolled materials, meeting the processing needs of different industries.

Coil Cut to Length Lines Services

As an experienced supplier of coil cut to length lines, KINGREAL SLITTING not only provides high-quality products but also offers one-stop services:

-Factory visit assistance: KINGREAL SLITTING encourages customers from around the world to visit the factory in person to gain a better understanding of KINGREAL SLITTING coil cut to length machine. A professional team will accompany you throughout the visit and provide detailed explanations of the coil cut to length lines.

-Customized coil cut to length machine solutions: Through multiple online and offline communications with customers, KINGREAL SLITTING can tailor personalized coil cut to length lines solutions to ensure that the coil cut to length lines perfectly matches their project needs. Every machine sold by KINGREAL SLITTING is designed to meet the unique needs of customers.

-On-site coil cut to length machine installation: After the coil cut to length lines arrive at the customer's factory, KINGREAL SLITTING professional engineers will travel to perform installation services and ensure that the coil cut to length machine runs smoothly under every design parameter. Installation is completed only after ensuring that the accuracy meets the standards.

-Spare parts supply: If parts wear out after long-term operation, KINGREAL SLITTING will quickly provide the necessary spare parts to ensure that the customer's production is not affected.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil