Introduction to Precision Cut to Length Line

KINGREAL SLITTING precision cut to length line is designed specifically for the metalworking industry, providing high-precision plate cutting solutions. Whether processing steel, stainless steel, aluminum, or other metals, this precision cut to length machine efficiently produces at speeds of up to 80 m/min, ensuring each product achieves precise length control, smooth edges, and minimal burrs. KINGREAL SLITTING precision cut to length line not only meets the stringent quality standards of various manufacturing industries but also plays a significant role in improving production efficiency and reducing costs.

This precision cut to length machine utilizes advanced automation technology and a user-friendly interface, allowing operators to monitor and adjust the system in real time. This design not only optimizes productivity, but also effectively reduces material waste and improves production consistency. With this precision cut to length line, customers can automate the entire process from uncoiling, straightening, deburring, cutting to length, and stacking, significantly enhancing production flexibility and efficiency.

KINGREAL SLITTING offers customized precision cut to length machine manufacturing solutions tailored to individual customer needs, ensuring each precision cut to length line is customizable to their specific dimensions and production requirements. The efficiency and precision of KINGREAL SLITTING precision cut to length machines significantly reduce overall processing time and minimize material waste. This not only brings significant economic benefits to customers but also enhances their market competitiveness. By using KINGREAL SLITTING precision cut to length lines, customers can better meet market demands, optimize production processes, and achieve efficient and stable production.

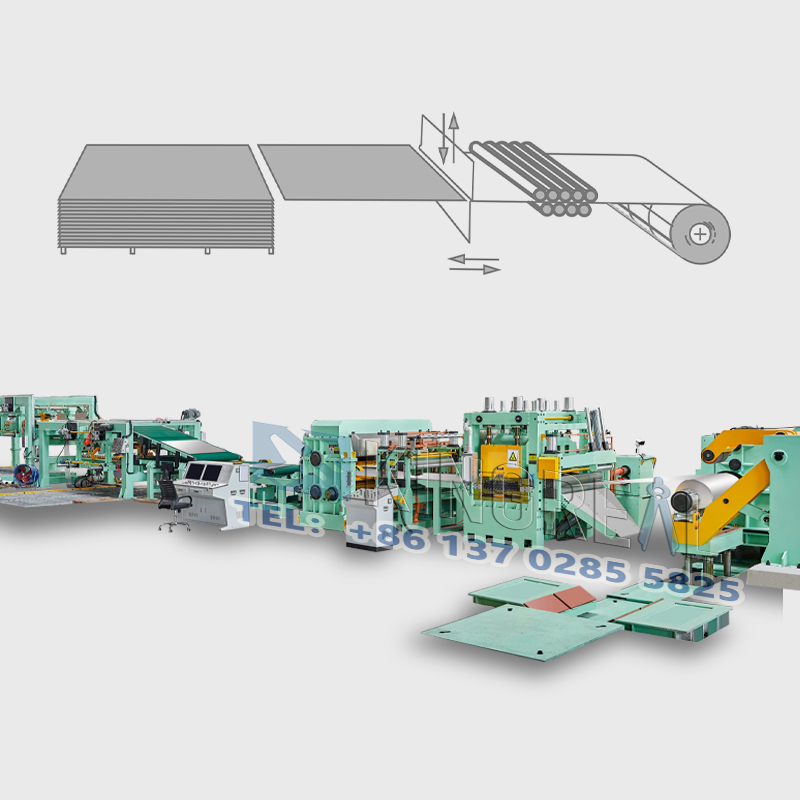

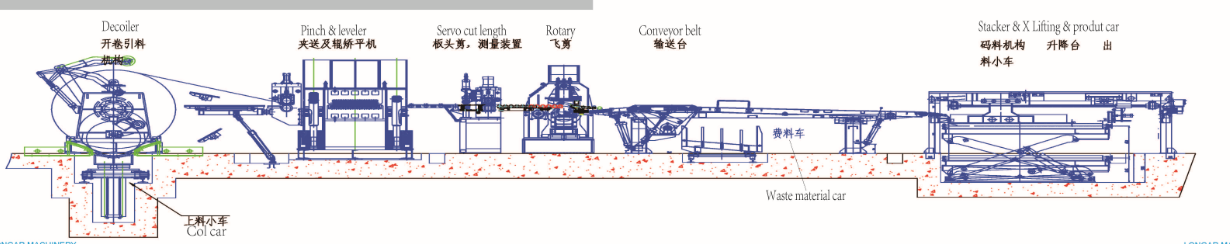

Working Process of Precision Cut to Length Machine

Trolley to load the coil -- Decoiler to feed the coil -- 2-roller pinch feeder to feed the coils forward -- 6-layer leveling machine for precision leveling -- High-precision cut-to-length machine -- Belt conveyor to convey sheets -- Auto stacking

Parameters of Precision Cut to Length Line

Material | steel, stainless steel, cold rolled, hot rolled, carbon steel, galvanized steel, etc |

Material width | 300-1600 mm |

Material thickness | 0.3-3mm |

| Speed of feeding | 0-80 m/min |

| Coil. I.D | 508-610 MM |

Coil. O.D | 1500 MM |

AIR SUPPLY | 5 kg/cm² |

Power | AC 380V |

"The data in this table is for reference only. KINGREAL SLITTING always designs and manufactures each precision cut to length machine according to each customer's specific requirements, ensuring that every customer can purchase a precision cut to length line that suits their needs."

Precision Cut to Length Line Design Concept

KINGREAL SLITTING precision cut to length machine design concept stems from a deep understanding of the metalworking industry and meticulous insight into customer needs. As a manufacturer specializing in high-precision precision cut to length lines, KINGREAL SLITTING engineers have incorporated several key elements into the design of this precision cut to length machine to ensure exceptional performance, efficiency, and flexibility.

1. Precision cutting for precision cut to length line

KINGREAL SLITTING precision cut to length machine utilizes an advanced servo-driven cutting system, enabling extremely precise cut-to-length cutting. This servo system allows the cutting length to be programmed according to the customer's specific needs, ensuring consistent and precise results for every cut. This high-precision cutting capability allows KINGREAL SLITTING precision cut to length line to meet stringent manufacturing standards while providing customers with greater flexibility to accommodate a wide range of specifications and materials.

KINGREAL SLITTING precision cut to length machine helps customers reduce material waste, lower production costs, and enhance the overall market competitiveness of their products through precise cutting.

2. Stable and reliable performance for precision cut to length line

The KINGREAL SLITTING precision cut to length machine is designed with a sturdy frame and high-quality components to ensure stability throughout operation. Even at high speeds, the machine minimizes vibration and noise. This stability not only improves processing smoothness but also extends the life of the precision cut to length line.

3. Customizable options for precision cut to length line

The KINGREAL SLITTING precision cut to length machine presents a range of selectable features to fulfill the particular production demands of various customers. Customers may choose a shearing technique depending on their processing needs, including fixed shearing, swing shearing, fly shearing, or rotary shearing. Furthermore, the precision cut to length line can be equipped with additional tools such as a laminating device, dual stackers, and dual leveling machines, providing maximum flexibility.

4. High-speed precision cut to length machine

The KINGREAL SLITTING precision cut to length line has been optimized by our engineers to deliver high-speed production capabilities, making it suitable for customers with large-scale production needs. The machine can quickly complete feeding, leveling, and cutting processes, ensuring excellent cutting accuracy while maintaining an efficient production pace.

5. Automatic stacking for precision cut to length machine

To further enhance production efficiency, the KINGREAL SLITTING precision cut to length line is equipped with an integrated automatic stacking system. This system automatically collects and organizes cut parts, reducing manual intervention and improving work efficiency. Customers can customize the stacking method based on size, quantity, or other requirements, flexibly meeting diverse production needs.

Main Components of Precision Cut to Length Machine

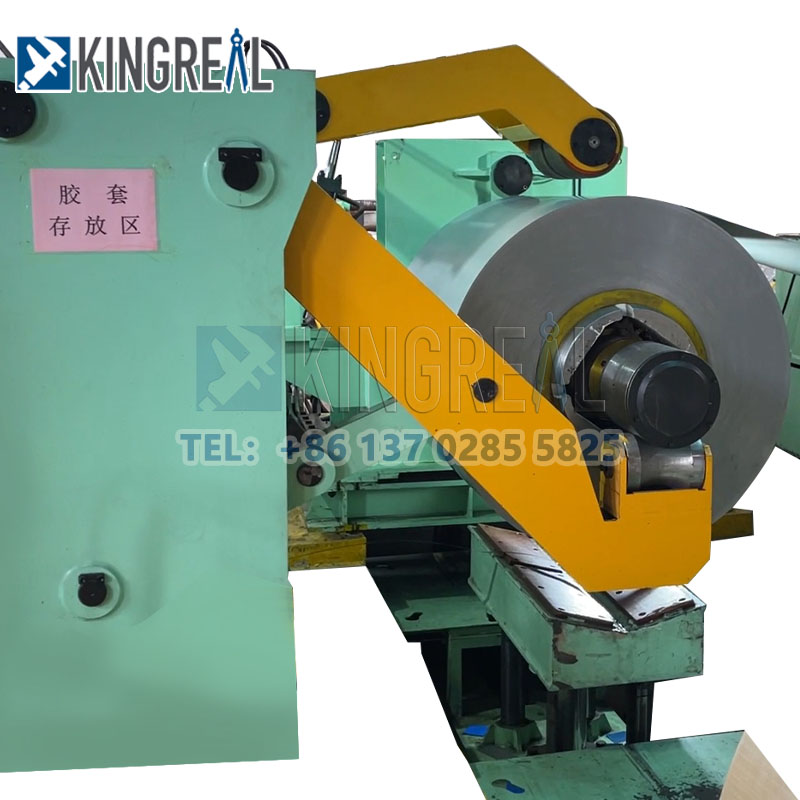

●Decoiler for precision cut to length line

The decoiler is a crucial component of a precision cut to length machine, ensuring the smooth feeding of metal coils into subsequent processing steps. The decoiler design includes several key components, including a material preparation table, a hydraulic lift trolley, a tension decoiler, and a shovel head retractable mechanism. These components are designed to improve operational efficiency and ensure material stability before shearing, laying a solid foundation for subsequent processing.

●Six-roller leveling machine for precision cut to length line

The six-roller leveling machine is the core equipment in a precision cut to length machine, responsible for leveling and straightening the sheet metal. Its primary functions include relieving internal stress and improving straightening accuracy. This leveling machine is suitable for a variety of metal materials, including steel and aluminum, to meet the processing needs of diverse customers. The precise performance of the leveling machine enables subsequent shearing with greater precision, thereby improving overall processing quality.

●Flying shear head for precision cut to length line

The flying shear head is a key cutting component in precision cut to length machines, responsible for fast and precise sheet metal shearing. Its key feature is its high-speed dual-crank rotation. This dual-crank design enables the flying shear head to continuously track and shear the sheet metal at high speed, significantly improving production efficiency. Advanced German servo control technology also enables high-precision control of the shearing process, ensuring that each cut meets standard length and quality.

●Pinch feed speed meter for precision cut to length line

The pinch feed speed meter is a crucial component for ensuring a stable material supply and precise cutting throughout the entire processing process. Its functions include synchronized tension generation and touchscreen control. The pinch feed speed meter design significantly enhances the operational convenience and reliability of the entire precision cut to length machine.

●Stacker for precision cut to length line

The stacker is a crucial post-processing device in precision cut to length machines, responsible for stacking and packaging processed sheets. With a maximum load capacity of 10 tons, this stacker is capable of handling large quantities of cut material. During the stacking process, the stacking machine design specifically considers the spacing between materials to avoid collisions between sheets and ensure the integrity and quality of the finished product.

Why Choose KINGREAL SLITTING?

KINGREAL SLITTING offers professional precision cut to length line manufacturing solutions, factory visits and machine inspections, machine installation, machine repairs, operator training, and spare parts provision, ensuring KINGREAL SLITTING provide customers with high-quality precision cut to length machines and comprehensive service.

√ Superior quality and exquisite craftsmanship

√ A genuine focus on customer satisfaction

√ Focus on precision cut to length machine quality and value

√ Complete precision cut to length line manufacturing on time and on budget

2025 Precision Cut to Length Line Project

In July 2025, KINGREAL SLITTING successfully completed a precision cut to length line project with an Indonesian customer. This project covered the entire process, from manufacturing, commissioning, to installation.

After the precision cut to length machine launch, KINGREAL SLITTING engineering team quickly engaged in precision cut to length line manufacturing and testing. After rigorous quality control and multiple commissioning sessions, the precision cut to length machine was successfully completed. KINGREAL SLITTING engineers then traveled to the Indonesian customer's factory to install the precision cut to length line. During the installation process, KINGREAL SLITTING engineers worked closely with the Indonesian workers to ensure that every step was carried out according to plan and that the precision cut to length machine could be put into production smoothly.

After the precision cut to length line was installed, KINGREAL SLITTING engineers conducted meticulous commissioning to ensure that the precision cut to length machine fully met the Indonesian customer's production requirements. During the commissioning process, KINGREAL SLITTING engineers carefully observed the precision cut to length line's operating status and adjusted parameters to optimize its performance, ensuring optimal performance in actual production.

KINGREAL SLITTING also gave Indonesian staff thorough operator training so that they could expertly run and maintain the precision cut to length machine. Machine startup and shutdown processes, production parameter changes, and basic maintenance techniques were all addressed in this course. By means of this training, Indonesian employees developed their overall skills by acquiring not only essential equipment operating abilities but also the ability to solve problems and carry out straightforward repairs.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil