What Is Tinplate Cut To Length Line?

Cut to length line, also called blanking line shearing type cut to length machine, specially designed for the uncoiling, leveling, cut to length and stacking of metal coils of various raw materials. It can produce metal plates of different widths according to the processing needs of customers and put them into the market as secondary processing raw materials.

According to the characteristics of the raw materials, the cut to length line will be different in production design, component configuration and knife holder production. The tinplate cut to length line is a cut to length line manufactured by KINGREAL SLITTING specifically to help factories process tinplate coils. Tinplate cut to length machine main function is to unroll the rolled tinplate material, cut it to the length set by the user through precise control, and stack it into neat plates. This equipment is particularly suitable for scenarios where fixed-size plates need to be mass-produced, such as packaging industries such as food cans and electronic component housings.

Generally speaking, the production process of tinplate cut-to-length line is that the tinplate metal coil is fed into the unwinding machine through the feeding trolley, and the material is gradually unwound. After the leveling machine eliminates the material stress, the feeding speed is adjusted to match the subsequent process through the buffer pit. The servo system drives the feeding mechanism to accurately feed the material according to the preset length, and the cut to length machine completes the cutting when the material stops. Finally, the sheared plates are automatically stacked by the conveying device and finally transported out by the hydraulic lifting trolley.

Main Components Of Tinplate Cut To Length Line

·Cut To Length Line Decoiler

The decoiler is responsible for unwinding the rolled tinplate coils and ensuring smooth material delivery by adjusting the tension.The hydraulic or pneumatic expansion shaft design is adopted, and the inner hole of the coil is clamped by a three-petal or four-petal support block to prevent the coil from sliding. Equipped with brakes and automatic centering system (CPC), the position of the coil is automatically adjusted during feeding to avoid deviation. It supports single-sided or double-sided support structure to adapt to coils of different weights (such as single-sided support below 10 tons and double-sided support above 15 tons).

According to the customer's cut-to-length plate processing needs, KINGREAL SLITTING can integrate a feed guide device, which can automatically untie the straps and guide the sheet into the subsequent process

·Cut To Length Line Leveler

The leveling machine is a core component in the tinplate coil processing technology. It helps eliminate the wavy deformation of the coil caused by curling or transportation, ensures the flatness of the plate, and can improve the quality and precision of the finished product.

KINGREAL SLITTING precision leveling machine usually adopts multi-roller leveling technology to eliminate internal stress through repeated bending. The more rollers, the better the leveling effect on the thin plate. And it is equipped with a buffer pit to adjust the synchronization of material conveying speed and subsequent processes to avoid damage to the surface tin coating due to uneven tension.

In response to the need to protect the surface coating of tinplate, the surface of the leveling roller is often covered with nylon or rubber material to reduce friction scratches.

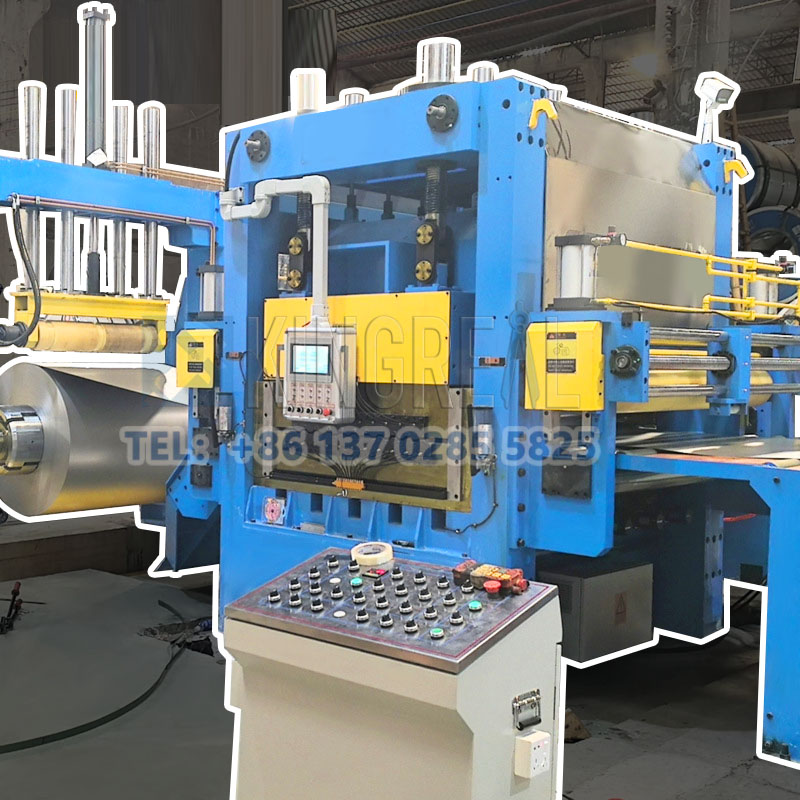

·Cut To Length Machine

The cut-to-length shearing machine accurately shears the plate according to the set length and is the core execution unit of the cut-to-length shearing production line.

KINGREAL SLITTING cut to length machine adopts a hydraulic drive system (provides stable shearing force, and the blade material is Cr12MoV or cemented carbide. The hardness reaches HRC53-58 after heat treatment, taking into account both wear resistance and sharpness. The full closed-loop control mode compensates for the slippage of the traction roller or the mechanical gap error to ensure that the shearing action is synchronized with the feeding.

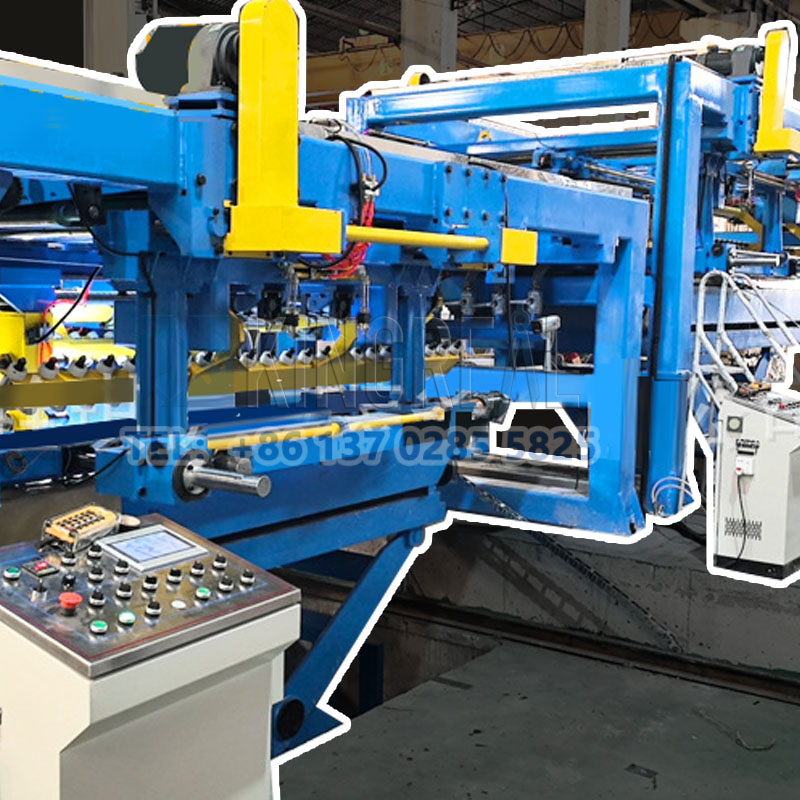

·Auto Stack

The stacking device of the cut-to-length shearing line is used to neatly stack the sheared plates for subsequent transportation or stamping.

Gantry-type stacking: equipped with a pneumatic blowing system and a roller device to prevent the plates from being scratched, suitable for high-precision stacking.

Open stacking: The left and right blocking devices are combined with a pneumatic flapping mechanism to quickly sort the plates and transport them to the hydraulic lifting trolley, suitable for large-sized plates. The automated stacking speed can reach 50-80 sheets/minute, and the stacking error is ≤0.15mm

Different Between Tinplate And Stainless Steel Cut To Length Line

Cut To Length Line | Raw Material | Design Feature | Application |

Tinplate Cut To Length Line | Tinplate (tin-plated thin steel plate) is a low-carbon steel with a thickness of usually 0.1-0.5mm, mainly thin plates, with good ductility and easy damage to the surface coating. | The tinplate cut-to-length shearing line uses a multi-roller leveler to eliminate the wave deformation of the coil, and adjusts the tension through a buffer pit to avoid scratching the tinned layer. The pinch roller driven by the servo motor cooperates with a full closed-loop encoder to control the shear length error within ±0.1mm, which meets the precision stamping requirements of food cans. The threaded rod and the T-type slider are linked to adjust the spacing of the moving plates to adapt to tinplates of different widths and avoid shear offset. | Tinplate cut-to-length lines are mainly used for thin-wall packaging such as food cans and electronic component housings. They need to adapt to large-scale, high-tempo production. The equipment emphasizes automated stacking and fast mold change. |

Stainless Steel Cut To Length Line | Stainless steel (such as 304 and 316 series) has high hardness, strong tendency to work hardening, and a thickness range of 0.5-6mm covering thin plates to medium and thick plates. | The stainless steel cut-to-length shearing line adopts a high-power hydraulic system or a mechanical crank structure. The blade material must be high-speed steel or carbide to resist wear. At the same time, tungsten carbide guide wheels and pressure plates are set to reduce friction damage on the stainless steel surface. | The stainless steel cut to length line is used for thick plate fields such as building structural parts and automobile fuel tanks. The equipment needs to be compatible with multiple processes such as flame cutting and laser cutting, and support remote parameter setting. |

About KINGREAL SLITTING

KINGREAL SLITTING is a professional coil processing equipment manufacturer from China, we can supply the whole solution for the coil slitting machine and cut to length line.In the field of cut-to-length shearing line design and manufacturing, KINGREAL SLITTING has helped customers in more than 30 countries complete hundreds of projects. KINGREAL SLITTING welcomes customers from all over the world to visit the coil processing equipment manufacturing plant, and let KINGREAL SLITTING help customers obtain long-term production benefits in various industries and markets.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil