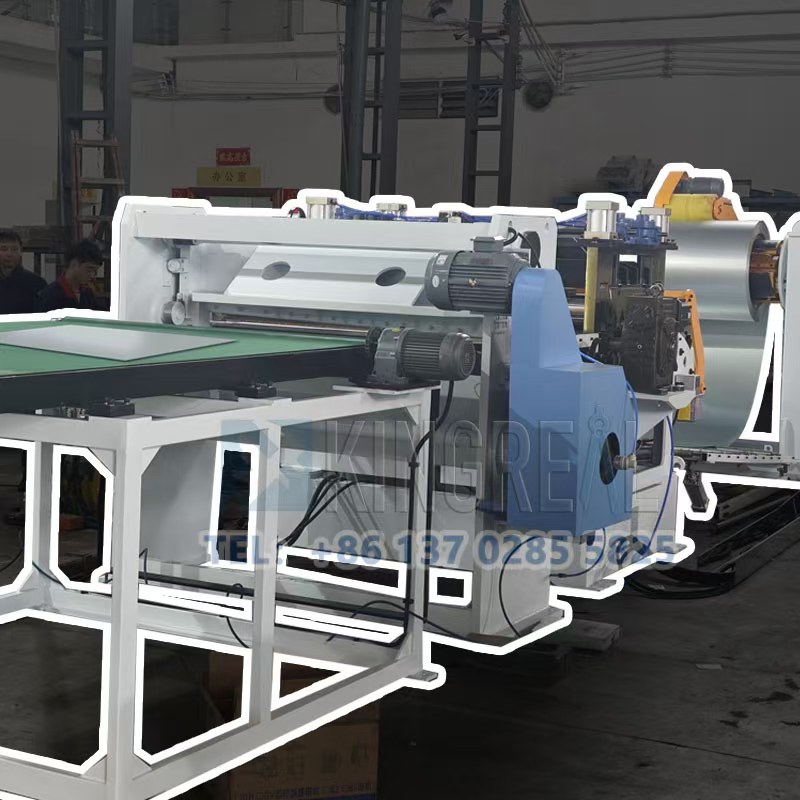

Video About Light Gauge Cut To Length Machine

Light Gauge Cut To Length Line : Standard Blanking Line Cutting System

KINGREAL SLITTING manufacturing the light gauge cut to length line is the standard blanking line cutting system, can cutting the 0.3-3mm thickness different material coil, such as aluminum, stainless steel, copper, rolled sheets, galvanized sheets, tinplate, etc, which can meet most of the metal processing. The light gauge cut to length line is high speed and precise metal coil cutting processing, which process of uncoiling, straightening, measuring, cross-cutting length setting and stacking workstations. The CTL lines consists of coil car, auxiliary stand, uncoiler, peeling device, leveler, coil guide, encoder scale, shear, conveying table, stack, output trolley, hydraulic system, etc.

The whole cut to length line is controlled by PLC with computer display, has a high degree of automation, good straightening effect, accurate cutting, high production efficiency, reliable performance and easy operation and maintenance. KINGREAL SLITTING offers a wide range of cut-to-length solutions, whether it's the basic parameters of the coil or the speed and quality of the product, KINGREAL SLITTING can re-engineer a light gauge cut to length line, to help our customers realize their cost-effective sourcing needs.

List Of Light Gauge Cut To Length Line Components

1. Hydraulic coil car

2. Hydraulic decoiler

3. Hydraulic entrance guide

4. Four / six high leveling machine

5. Ring bridge

6. Side guide pulley

7. CNC servo feeding straightening machine

8. Measuring system

9. Shearing machine

10. Conveyor table

11. Pneumatic unloading device

12. Hydraulic lifting table

13. Unstacking car

14. Hydraulic system

15. Pneumatic system

16. Electrical system PLC control

Working Process Of Cut To Length Line

Feeding trolley → Deoiler → Traction head, pinch feed roller feeding → High precision leveling device → Cut to length shearing → Unloading table / automatic stacking table

Light Gauge Cut To Length Line Specification

| Processing Thickness | 0.3~3mm |

| Processing Width | 600-2000mm |

| Cut to length Accuracy | ±1.5 mm |

Cutting Speed | 10-70m/min |

Coil Inner Diameter | 500/610 mm |

Coil Outer Diameter | ≤2000 mm |

Cut to Length Range | 500~4000mm |

Sheet Leveling Flatness | ≤±1.5mm/m² |

Length tolerance | ≤±1.5mm /2m |

Diagonal tolerance | ≤±1.2mm/2m |

Levelling precision | ≤2mm/m2 |

Cut length | 500~3000m |

Main Component Details

1. Decoiler Unit

The cut to length machine decoiler our sizing unit allows multiple strands of coils to be pre-positioned on the loading station. It is available with a single or double head to suit different requirements.

2. Straightener

Cut-to-length line leveler can have different designs from 2H, 4H or 6H. It can be flexibly controlled for good leveling of the sheet. Its leveling rolls are made of roll steel with chrome plated surface. It has good wear resistance and long service life.

3. Feeder and shear

Cut-to-length lines use one or two pairs of feeding rollers, driven by AC servo motors, to feed the strip to the set length precisely. They ensure fast positioning with minimal errors. These feed rollers are compatible with hydraulic shears or pneumatic clutch shears for fast cutting and easy gap adjustment. They can be equipped with roller or belt conveyors.

4.Stacking unit

CTL Line can be equipped with pneumatic or electromagnetic stacking units. It is equipped with a blower to protect the surface from scratching. Both longitudinal and transverse stacking are available.

Feature Of Light Gauge Cut To Length Machine

1. Cut to length line has 7-inch large Mitsubishi touch screen control, with buttons and touch screen dual control mode. The screen instructions are clear and simple to operate.

2. Cut to length machine use the PLC operation panel in an independent electrical box, completely avoiding the negative impact of punch vibration on feeding accuracy, ensuring high precision feeding.

3. Serrated CNC feeding machine has memory function. When the feeder suddenly loses power or needs to interrupt production due to special circumstances, there is no need to re-measure the program when restarting production. Simply press the reset button and it will run again. Simplify the operation procedure.

4. There are two types of relaxation: two ends relaxation and one by one relaxation. One machine can be used for different stamping processes.

5. Advanced automatic diagnosis system, when the operation is faulty, the system can self-diagnose and display the error information in detail.

6. CTL line has two feeding methods, pointing and continuous feeding. It can be mixed operation, X-axis (single axis) can work independently, or X-axis and Y-axis can be linked, or both axes can be fed alternately. Save material cost.

7. High precision: In the process of continuous feeding, the minimum distance between the edge and the side can be set within 0.4mm, and the error of each movement can be guaranteed within ±0.05mm.

FAQ: How many coil sizes can CTL process?

Thickness(mm) | Width (mm) | Width (mm) | Max sheet length (mm) |

0.2-2 | 100 - 750/1250/1600 | 10 | 1000/ 2500/3000 |

0.3-3 | 500 - 1250/1600 | 15 | 500-4000 |

0.5-4 | 500 - 1250/1600 | 15 | 500-4000 |

1-6 | 600 - 1250/1600 | 20 | 500-6000 |

2-8 | 600-1250/1600/2000 | 25 | 500-8000 |

3-10 | 600-1250/1600/2000 | 25 | 1000-12000 |

4-12 | 600-1250/1600/2000 | 25 | 1000-12000 |

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil