Video About Compact Cut To Length Line

Compact Cut-to-length Lines: Helping You Start New Projects Fastest

Compact cut-to-length line is specially used in the field of coil processing and production to produce metal sheets of specified width through the process of leveling, shearing and stacking of metal coils to be put into secondary production. The types of Cut-to-length lines are related to the thickness of the raw material, the method of cutting and the design of the cut to length line, and are usually categorized into:

Ø Different thicknesses:

1. Heavy Gauge Cut To Length Line: Used to cut metal coils with a thickness range of 6-25MM;

2. Light Gauge Cut To Length Line: for cutting metal coils with a thickness range of 0.3-3MM.

Ø Different cutting methods:

1. Fly Shearing Cut To Length Line: Flying shear cutting design, to realize the non-stop cutting, production speed can reach 80m/min.

2. Stop To Shearing Cut To Length Machine: Adopting fixed shear design, the shearing process needs to be stopped to cut, to realize the precision of the cutting effect

3. Rotating Shear Cut To Length Line: rotating shear blade cuts the metal strip into predetermined lengths1. The rotary shear allows for continuous cutting, meaning The rotary shear allows for continuous cutting, meaning the strip moves through the machine without stopping

Ø Different design categories:

1. Double leveling cut-to-length line: a cut-to-length line that realizes precision leveling effect to meet the production needs of products with high surface leveling requirements.

2. Double-stacking cut-to-length line: Equipped with double-stacking table, it realizes fully automatic cut-to-length production process and matches the production speed of high-speed shearing.

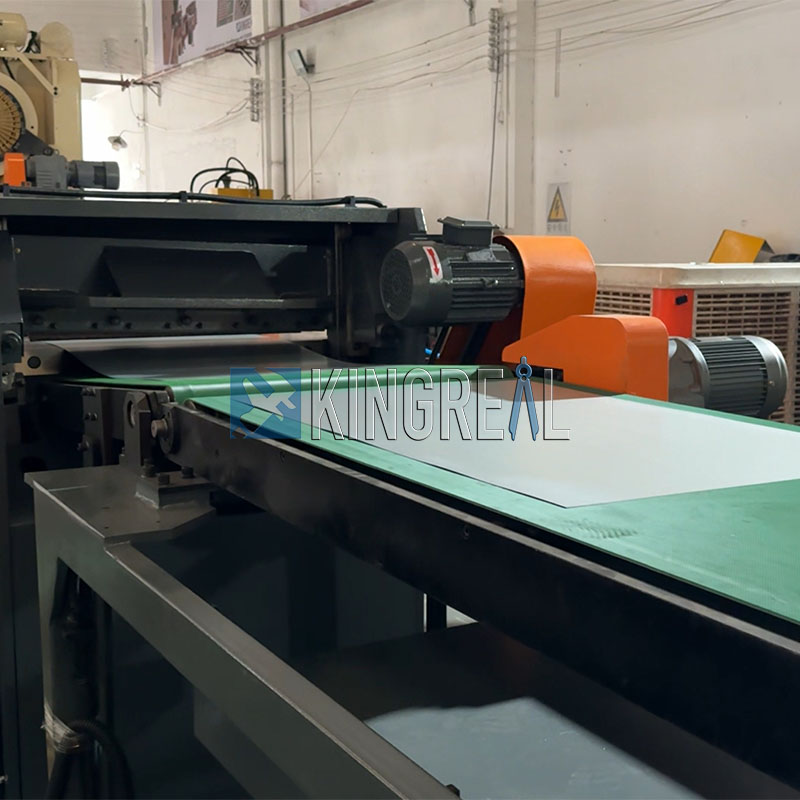

3. Compact cut-to-length lines. Efficient metal processing equipment designed for limited space, capable of cutting metal coils to the exact length required.

Cut To Length Line Technical Specification

·Coil Thickness: 0.3-2mm

·Coil Width: 700MM

·Coil I.D: 508mm

·Coil O.D: 1500mm

·Weight: 5T

·Total Weight Of Machines Around: 30T

·Production Line Power: 380V/50Hz/3Ph

·Line Speed: 0-20m/min

·Capacity Around: 75Kw

Main Component Detail Of Compact Cut To Length Machine

· Decoiler System For Cut To Length

Usually equipped with a hydraulic or electric decoiler to unroll and flatten the metal coil, ensuring that the metal strip remains smooth and undamaged during the unrolling process.

· Length Measuring System For Cut To Length Line

Accurately measures the length of the strip to ensure that each cut is made to the required length. High precision sensors and control systems are used to monitor and adjust the measurement data in real time.

·Cutting System For Cut To Length

Precise cutting of metal strips, continuous cutting process ensures high productivity and high cutting accuracy.

· Conveyor System For Cut To Length Line

Conveyor System transports the cut sheet metal to the stacking unit. Automated conveying increases the overall efficiency of the production line.

·Auto Stacker For Cut To Length

Automatically stacks the sheared metal sheets neatly for subsequent processing or packaging.

Advantage Of Compact Cut To Length Line

1. Space-saving: compact design makes the layout of the machine more compact and saves floor space.

2. High-efficiency production: Integration of multiple functions such as unwinding, leveling, cut-to-length shearing and stacking realizes integrated high-efficiency production.

3. Precision control: Advanced measuring and cut to length technology ensures precise dimensions of each sheet.

4. Versatility: suitable for handling various types of metal materials, including cold rolled steel, hot rolled steel, stainless steel, etc.

5. High degree of automation: Equipped with modern automatic control system to reduce manual operation and improve production efficiency.

Final Product Display

FAQ:Why don't compact cut-to-length lines need a leveler?

1. Compact cut-to-length lines are often used to handle thinner and uniform-quality metal coils, which have already been preliminarily leveled during the production process and have a good surface flatness. Therefore, additional leveling machines are not necessary.

2. Compact cut-to-length lines emphasize a small footprint and efficient equipment layout. Omitting the leveler reduces the overall size and complexity of the equipment, making the line more compact and efficient.

3. Omitting the leveler significantly reduces the initial investment and maintenance costs of the equipment, while reducing energy consumption. This is especially important for small plants or companies with limited production space that need to save on budgets.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil