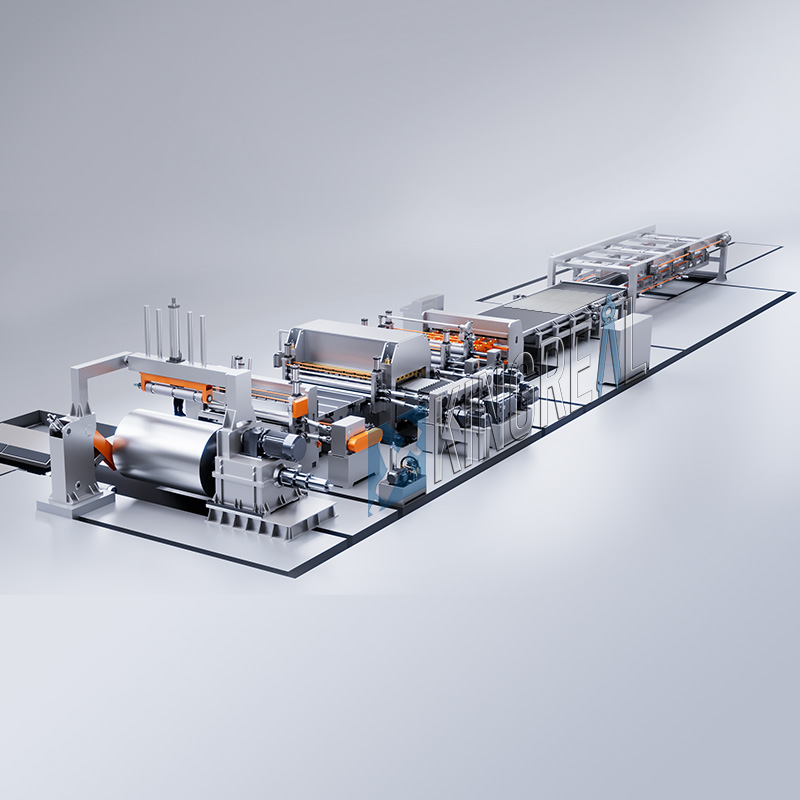

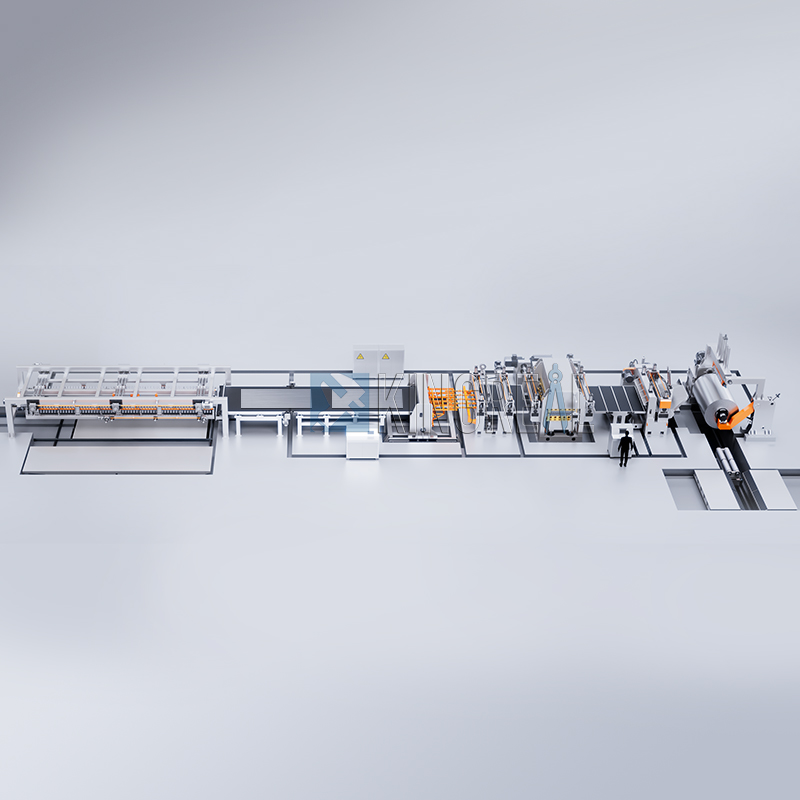

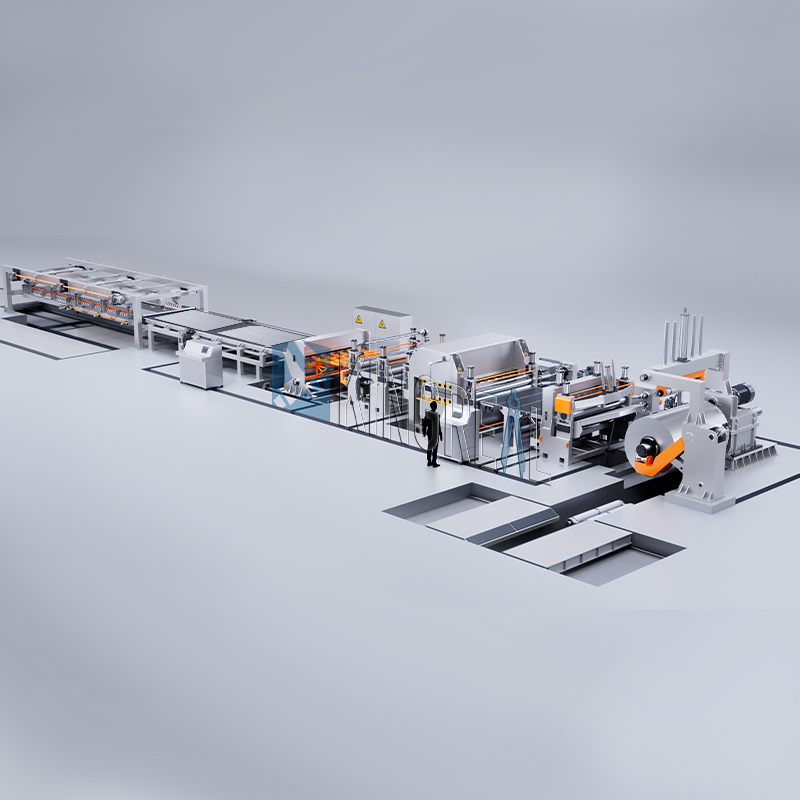

Automatic Cut To Length Machine Description

Automatic cut to length machine (also known as: wide metal straightening and sizing line/high-speed precision leveling and shearing system) is a fully automatic sheet finishing system designed specifically for the steel processing industry, which adopts a dynamic shearing tool system to realize accurate cut to length of the strip material on the move. KINGREAL SLITTING automatic cut to length machine innovatively adopts closed-loop servo control system to adjust cutting parameters (including cutting length ±0.25mm and feed rate) in real time during continuous feeding process, effectively breaking the efficiency bottleneck of traditional downtime shearing and improving the efficiency of aluminum/steel sheet processing by up to 300%.

Meanwhile, the six-roller leveling machine is equipped with 21-roller composite straightening technology for stress relief treatment of coils within 1600mm width, ensuring that the straightness of the finished panels meets the international standards (thickness error per square meter ≤ 0.25mm), and completely eliminating the wavy deformation defects generated by the traditional process. Thanks to the synergistic control of German Siemens PLC and Omron sensing system, the maximum running speed of automatic cut to length line exceeds 100m/min, which, together with the pneumatic lifting arm and high-pressure air blowing and slowing down device, forms a full-process intelligent production system from decoiler, leveling, cut to length machine, edge cutting to stacking.

Feature Of Automatic Cut To Length Machine

1. Intelligent control system integration advantage.KINGREAL SLITTING automatic cut to length line adopts imported high-performance PLC system from Germany Siemens/Japan Mitsubishi, etc., and realizes the whole process automation control of metal cut to length line from unwinding, leveling to shearing through modular programming. Metal cut to length machine is equipped with five-axis linkage CNC numerical control system, combined with laser range finder real-time feedback sheet deformation data, automatic correction of blade gap, to meet the needs of a variety of material cutting.

2. KINGREAL SLITTING automatic cut to length machine integrates rare earth permanent magnet servo motor (such as YASKAWA Σ-7 series) and planetary reducer, with torque control accuracy of ±1% and response speed of ≤0.1ms. The Steel cut to length line adopts Rexroth A10VO axial piston pump set, equipped with double closed-loop control of pressure and flow rate, realizing stable output under shear force of 16000KN.

3. Intelligent production management features. Automatic cut to length line is equipped with high-resolution CCD vision system (detection accuracy 0.02mm/m²) and laser encoder, realizing real-time board length measurement (±0.25mm) and defect identification. 200 groups of process parameters are preset in Steel cut to length machine through human-machine interface, supporting 0.2-25mm thickness, 650-25mm thickness, and 650-25mm thickness. 25mm thickness and 650-2500mm width.

Technical Specification Of Automatic Cut To Length Line

Model | Raw Material | Thickness (mm) | Width(mm) | ID(mm) | OD(mm) | Weight(T) | Cutting Weight | Length Accuracy(mm) | Speed(m/min) | Main Power(kw) |

2.0×500 | 1.Stainless steel 2.Cold rolled steel 3.Galvanized steel | 0.2-2.0 | 200-500 | Φ508 | ≤Φ1200 | ≤6 | 300-1500 | ≤±0.5 | 15~50 | ~75 |

2.0×650 | 0.2-2.0 | 200-650 | Φ508 | ≤Φ1200 | ≤6 | 300-1500 | ≤±0.5 | 15~50 | ~75 | |

2.0×1300 | 0.3-2.0 | 500-1300 | Φ508/610 | ≤Φ1500 | ≤15 | 500-3500 | ≤±0.5 | ≤50 | ~95 | |

2.0×1600 | 0.3-2.0 | 500-1600 | Φ508/610 | ≤Φ1600 | ≤15 | 500-4000 | ≤±0.5 | ≤60 | ~122 | |

2.6×1850 | 0.5-2.6 | 400-1850 | Φ508/610 | ≤Φ1500 | ≤20 | 400-4000 | ≤±0.5 | 8~80 | ~180 | |

3.0×1600 | 0.3-3.0 | 500-1600 | Φ508 | ≤Φ1500 | ≤20 | 500-4000 | ≤±0.5 | ≤40 | ~90 | |

4.0×1600 | 1. hot rolled steel 2. Q235,Q345,B510 3.hot rolled stainless steel | 0.6-4.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤20 | 1000-12000 | ≤±1.0 | ≤50 | ~100 |

6.0×1600 | 1.0-6.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤30 | 1000-12000 | ≤±1.0 | ≤30 | ~155 | |

8.0×1600 | 2.0-8.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤35 | 1000-12000 | ≤±1.0 | ≤20 | ~180 | |

9.0×1600 | 2.0-9.0 | 600-1600 | Φ508/610 | ≤Φ2000 | ≤20 | 1000-12000 | ≤±1.0 | ≤20 | ~170 | |

10×1600 | 2.0-10 | 800-1600 | Φ508-Φ760 | ≤Φ2000 | ≤35 | 1000-12000 | ≤±1.0 | ≤30 | ~240 | |

12×2000 | 3.0-12 | 1000-2000 | Φ508-Φ760 | ≤Φ2000 | ≤35 | 1000-12000 | ≤±1.0 | ≤16 | ~255 | |

12×1800 | 3.0-12 | 800-1800 | Φ508-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±1.0 | ≤16 | ~255 | |

16×2000 | 4.0-16 | 1000-2000 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | ≤12 | ~275 | |

20×2200 | 5.0-20 | 900-2200 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | 10~16 | ~220 | |

22×2200 | 5.0-20 | 900-2200 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | 10~16 | ~220 | |

25×2200 | 5.0-20 | 900-2200 | Φ610-Φ760 | ≤Φ2200 | ≤35 | 1000-12000 | ≤±2.0 | 10~16 | ~220 |

Main Component Detail For Auto Cut to Length Line

1.Cut To Length Line Pilot Unit, Clamping Unit, Five Roller Leveling Unit

Cut To Length Line Pilot Unit is the first process when the sheet material enters the production line, and it assumes the functions of uncoiling guidance and tape threading assistance. It adopts double-roller counterpressure structure, and the electromagnetic speed-regulating motor drives the rotation of the counter-roller to pull the head of the coil to the subsequent workstation.

Cut To Length Line clamping device adopts AC servo motor (such as Yaskawa Σ-7 series) and planetary gearbox combination, torque control accuracy of ±1%. The upper and lower nipping rollers (hard chrome plated surface, hardness HRC58-62) apply 20-50kN clamping force through hydraulic cylinders to ensure non-sliding rolling feeding under the working condition of 0.1-3.0mm plate thickness.

Cut to length coil line five-roller leveling machine adopts “2 upper and 3 lower” asymmetric roller system layout, the upper roller group is fixed on the rigid slide, the lower roller configuration hydraulic lifting mechanism. The material of leveling roller is 45# steel with high frequency quenching treatment, through the harmonic attenuation straightening principle to eliminate the wave deformation of the plate, and the straightness can reach ≤0.25mm/m².

2. Cut To Length Machine Cut to length machine, waste edge material take-up machine

Split cutting machine adopts modular design of adjustable width spacer assembly (thickness tolerance ±0.05mm), through the hydraulic locking mechanism to realize quick changeover with precision grinding guide rail to achieve longitudinal shear width stepless adjustment.

The waste edge take-up machine of the cut-to-length line is the key auxiliary equipment of the sheet metal processing line, mainly used for automatic take-up of the metal waste edge after shearing and slitting. In the longitudinal shearing or transverse shearing process, the cut-to-length edge (usually 3-50mm in width) on both sides of the sheet is wound into a compact coil for subsequent transportation and recycling, which can increase the value of the waste material by 15%-20% compared with that of the shredding process.

3. Cut-to-length line six-roller leveling machine

Automatic cut-to-length line adopts a six-roller 21-roll sheet leveling machine, which passes through the leveling machine to achieve the effect of leveling the rolled metal sheet. It consists of feed haul-off rollers, upper and lower leveling rollers, upper and lower support rollers, machine frame, upper rollers press down adjusting device, transmission system ......, etc. It eliminates the residual stress and deformation of the coil through the structure of multi-layer rolls to make sure that the sheet material achieves the high-precision flatness.

4. Cut To Length Machine

The cutting machine of cut to length line is the core equipment of the sheet metal processing line, responsible for cutting the continuous sheet material according to the preset length with high precision. The steel strip is output by the CNC computer-controlled cut-to-length device according to its set length, and the signal is transmitted to the machine for receiving, which is the equipment that automatically cuts the steel strip horizontally.

Advantage Of KINGREAL SLITTING Cut To Length Line

"As a manufacturer of coil processing equipment, KINGREAL STEEL SITTING is committed to designing and manufacturing the best Cut To Length Line solutions for our customers, taking into account the customer's raw material parameters, secondary processing applications, plant inputs, local market positioning and other factors to customize the design and help our customers to obtain long-term production benefits."

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil