Video About How To Choose Cut To Length Line

Blanking Line For Cut To Length Machine

Cut to length machine is one of the most common uses of blanking line.Cut to length machine is mainly used to cut metal coils into flat sheets or sheets of a certain length.Large rolls of metal material are unrolled, straightened by a leveling machine, and then cut into sheets at a preset length.Cut to length line is capable of Handle metal coils of various thicknesses and widths, including steel, aluminum, stainless steel, etc. It features a high degree of automation and is equipped with an advanced control system for efficient and precise cutting. Ideal for metal sheets that require standard sizes, such as in the construction, manufacturing and appliance industries.

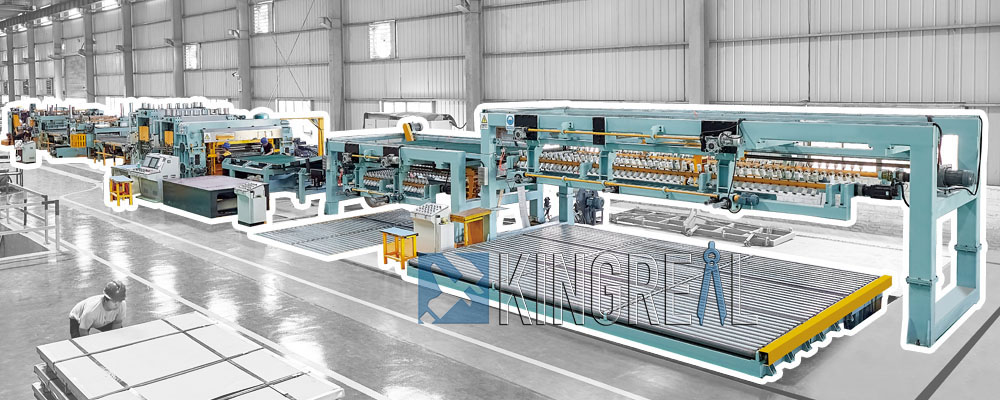

KINGREAL SLITTING designs and manufactures Cut To Length Machine with the features of high production speed, good leveling effect, high quality cutting and stacking accuracy, etc. High precision production and processing effect is realized through the design of high-precision leveling, flying shear device and gantry stacking and other devices.

Main Components For Cut To Length Line

·Uncoiler For Cut To Length line: Unrolls and transports the metal coil into the production line. The Uncoiler maintains a continuous supply of coils so that the line can work without interruption.

·Leveler For Coil Cut To Length:Used to straighten metal coils so that they are flat and free of ripples. This step ensures a high surface quality and good flatness of the cut sheet.

·Feeder: Precise transportation of the leveled sheet metal to the shearing unit. The feeder is usually equipped with a precise positioning and measuring system to ensure that each piece is cut to the same length.

·Shear Or Cutting Unit: cuts sheet metal to a preset length. The shear unit can be mechanical or laser cutting, depending on the design of the machine and the application requirements.

·Conveyor Belt: Conveys the cut sheet metal to the stacking area. The conveyor belt ensures the stability and smoothness of the sheet during transport.

·Stacker For Cut To Length Machine: Automatically collects and stacks cut sheets for subsequent handling and transportation. Stackers can usually be adjusted in height and arrangement to suit different production requirements.

Working Process Of Cut To Length Line

Raw material coil lifted to Material Storage Table → Material Upload → Automatic vertical Laser Centering → Pressing down material coil → Remove strap → Uncoiler feeding material → Pinch Rollers to enter the 6 layers precision Leveling Machine → Short Looper Station → Side Guide mechanism → Feeding-to-length → Fly Shearing Machine → Belt Conveying Device → Products Stacking → Discharging Trolley

Technical Specification Of Cut To Length Machine

NO. | NAME | SPECIFICATION |

| 1 | Raw Material | CRC STEEL |

| 2 | Thickness | 0.4-3.0mm |

| 3 | Width | ≤1500mm |

| 4 | Coil outer diameter | ≤Φ1800mm |

| 5 | Coil inner diameter | Φ508mm、Φ610mm(With rubber sleeve) |

| 6 | Coil weight | ≤ 20T |

| 7 | Speed | 0~80m/min (Stepless speed regulation) |

| 8 | Strip through speed | 0~15m/min |

| 9 | Contro | AC frequency conversion control |

Whole Solution Of Cut To Length Machine

"KINGREAL SLITTING Cut To Length Machine can deal with the thickness range of 0.3-20MM, width range of 500-2000MM of different metal materials coil, cut to length into the specified size, and finally stacked material production process. Depending on the production requirements, KINGREAL SLITTING can offer the following solutions"

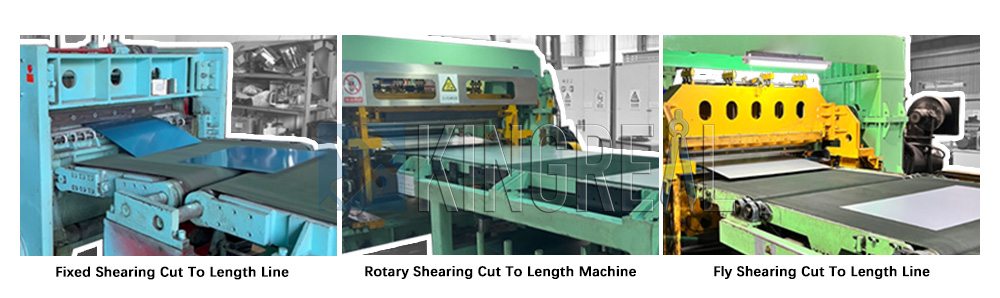

·Different Shearing System Cut To Length Machine

“In order to help our customers to solve the needs of customized shearing lines in terms of production speed and shear shape, KINGREAL SLITTING offers cut to length lines with different shear types.”

1. Fly Shearing Cut To Length Line

Fly Shearing Cut to Length Machine is a highly efficient metal processing machine used to accurately cut metal coils to specified lengths without stopping the feed, with a production speed of up to 80M/min, which can effectively improve production efficiency and meet the production needs of large-scale coil processing.

This cut to length machine is used to cut metal plates to a specified length, as measured by the NC feeder. The machine operates with a double crankshaft that drives the blade for precise rotation and cutting. Both the upper and lower knife holders are moved by the crankshaft, ensuring accurate positioning. The system consists of a movable knife holder, a gear box, and a servo power supply device. It features an adjustable cross-cutter clearance, which can be conveniently and quickly modified from the outside to accommodate different plate thicknesses. Additionally, the machine is equipped with an automatic forced lubrication system that supplies oil continuously, ensuring long-term mechanical lubrication of the unit.

This advanced cut to length line design enhances efficiency and maintains the quality of metal plates during the cutting process.

2. Stop To Shearing Cut To Length Line

The Stop To Shearing Cut To Length Line is a machine used to cut metal coils to a fixed length, the coils are cut to a preset length after passing through the leveler and the feed must be paused at each cut to ensure the exact length. The production speed of this cut to length line is about 20M/min, it can handle 0.3-3MM metal coils, which can meet most of the metal processing production needs.

Compared with the fly shearing cut to length line, the stop to shearing cut to length line

Lower production costs, reduced circulation pit design, smaller factory footprint. This is definitely a better solution for customers who have limited available factory space and do not have a high production output requirement.

3. Rotary Shear Cut To Length Machine

The Rotary Shear Cut To Length Machine utilizes rotating blades to quickly and accurately cut metal coils as they run, the Rotary Shear cuts with high precision to ensure consistent length and quality from sheet to sheet.

Adopt CNC servo system control, PLC control length measurement, length, shear times, speed and other information can be input into the PLC system, automatic stop after reaching the required number of shear times, adjustable line speed, equipped with high-precision encoder, the whole line is automated, easy to operate, and cut out the plate is flat and smooth.

·Different Production Configurations Are Available: Cut To Length Line

1. Double Leveler For Cut To Length Line

The cut to length line can be equipped with two leveling machines to improve the flatness and cut quality of the sheet metal and to ensure that the final product meets the high standards required.

The first leveler is primarily used for preliminary leveling, unrolling the coil and removing most of the corrugations and unevenness. This step ensures that the material has a basic flatness when it enters the subsequent process and reduces the difficulty of subsequent processing.

A second leveler is used for fine leveling, further straightening the material to ensure it meets higher flatness requirements. This is especially important for applications that require high precision cutting and surface quality, such as automotive manufacturing and appliance industries.

2. Double Stack For Coil Cutting Machine

The Cut To Length Line improves productivity and product quality by equipping it with Double Stack. While one stacking table is stacking cut sheets, the other stacking table is ready for the next stack. This reduces downtime, keeps the line running continuously and increases overall productivity. Equipped with two stacking tables can be flexibly adjusted according to different production needs, such as handling different sizes and quantities of plates, increasing the adaptability of the production line.

Final Product Display:

Want a customized Cut To Length Line solution?

1.Coil Material

2.Coil Width

3.Coil Thickness

4.Coil Weight

5.Cutting Length

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil