Video About Medium Gauge Cut To Length Line

High Precision Medium Gauge Cut To Length Line

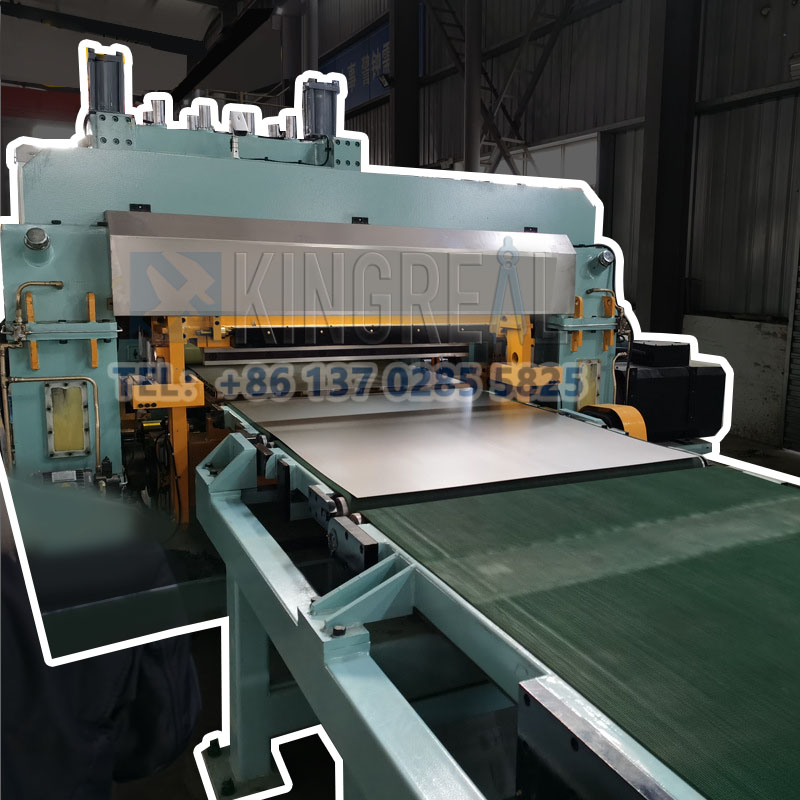

KINGREAL SLITTING Medium Gauge Cut To Length Line is the intermediate between the Light Gauge Cut To Length Line and the Heavy Duty Cut To Length Line, and is designed for uncoiling, leveling, shearing, and stacking of metal coils with a thickness of 4-10MM. The Medium Gauge Cut To Length Line is designed to handle the cutting of medium-sized metal coils, usually with carbide cutting tools for higher hardness and wear resistance, and a drive system using high-powered hydraulics or servo motors to ensure precision and stability of the cut.

Medium Gauge Cut To Length Line is equipped with advanced automation control system, which usually includes numerical control (CNC) and PLC control, to realize high precision cutting and complex machining process. The operation interface is friendly and easy to use, improving productivity and quality control. The Medium Gauge Cut To Length Line straightens and cuts medium gauge coils into sheets for the next process in the metalworking industry.

About Cut To Length Line

◇Application: Suitable for cutting metal coils into sheets/plates.

◇Advantages: easy to operate, the cut-to-length quality is high, excellent material utilization, step-less shear speed adjustment, etc.

◇Structure: It consists of uncoiler‘s, feeding and positioning, cutting unit, heap, etc.

◇Applicable materials: Tinplate, silicon steel, aluminum, copper, stainless steel and galvanized steel, etc.

◇Higher positioning: We focus on the top 30% of our industry‘s mid to high end customers, providing them with higher quality and higher production efficiency

◇Higher cost performance: We have been doing our best to design and manufacture higher cost performance machine lines for our customers, because we understand that this is one of the key factors for them to gain a leading position in the market competition

Medium Gauge Cut To Length Machine Specification

| 1 | Raw material | Stainless Steel Coil,200 series, 300 series, 400 series |

| 2 | Sheet thickness | 4.0~10.0mm |

| 3 | Sheet width | 500~1650mm |

| 4 | Machine input net width | 1650mm |

| 5 | Maximum coil weight | 25T |

| 6 | Operating speed | 0~30m/min (Stepless) |

| 7 | Loading speed | 0~8m/min |

| 8 | Total power | ~350KW |

| 9 | Input Voltage | 3 Phases 415V 50HZ |

Medium Gauge CTL Line Components List

| No. | Name | Qty |

| 1 | Coil Storage Station | 1 Set |

| 2 | Trolley (Hydraulic power | 1 Set |

| 3 | Uncoiler | 1 Set |

| 4 | Hydraulic Pilot Machine | 1 Set |

| 5 | Hydraulic feeding & leveling machine | 1 Set |

| 6 | Roller Conveyor | 1 Set |

| 7 | Materials guide machine | 1 Set |

| 8 | Eleven-rollers Main leveling machine | 1 Set |

| 9 | Pneumatic sizing device | 1 Set |

| 10 | Tailboard feeder | 1 Set |

| 11 | Hydraulic Shearing machine | 1 Set |

| 12 | Conveyor | 1 Set |

| 13 | Products thrower | 1 Set |

| 14 | Auto Stacker | 1 Set |

Coil Cut To Length Machine Component Details

◇Loading Trolley

The Loading Trolley is a critical component of the medium and heavy gauge cut to length line. It is responsible for moving steel coils from the storage area to the hydraulic decoiler. With its ability to move both horizontally and vertically, the trolley ensures precise positioning of the coils onto the uncoiler, thus enhancing production efficiency.

◇Hydraulic Decoiler

The Hydraulic Decoiler supports and uncoils the steel coils in the cut to length machine. It features a hydraulic cylinder that adjusts to accommodate the inner diameter of the coils, ensuring they remain stable during the uncoiling process. The hydraulic decoiler primary function is to provide a continuous and uniform material feed for subsequent processing steps.

◇Main Leveling Machine

The Main Leveling Machine is the core equipment in the cut to length line, used to level the steel plates and ensure a smooth surface. Comprising multiple leveling rollers, this machine repeatedly bends and straightens the steel plates to eliminate internal stresses and surface defects. The precision and efficiency of the main leveling machine directly affect the final product quality.

◇Hydraulic Shearing Machine

The Hydraulic Shearing Machine is responsible for the precise cutting of leveled steel plates. Driven by a powerful hydraulic system, this machine uses high-precision shearing blades to cut the plates to the required dimensions and shapes. The hydraulic shearing machine is characterized by its strong shearing force and high cutting precision, making it suitable for processing medium and heavy plates.

◇Auto Stack

The Auto Stack is the final key component of the cut to length line, used for automatically stacking the sheared steel plates. This device organizes the plates into neat stacks according to preset programs, reducing the need for manual intervention and increasing the automation level and efficiency of the production line.

About KINGREAL SLITTING

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil