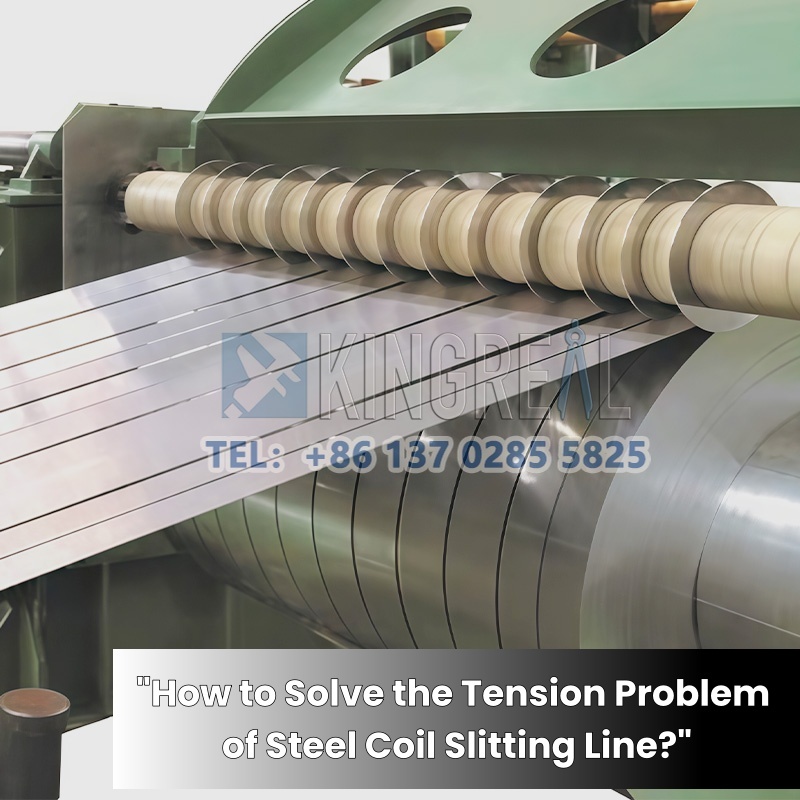

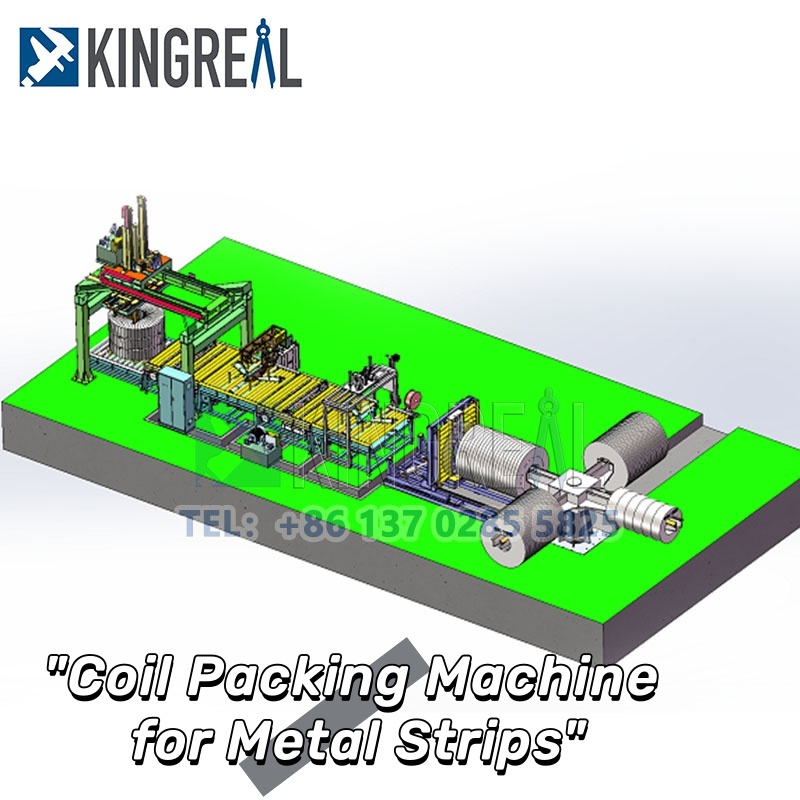

The steel slitting machine production line is generally divided into four main parts: decoiler, precision disc knife holder, (belt, plate tension generating station), winder, etc., Of course, there are also auxiliary devices such as material transport, clamping machine, plate head shearing machine, buffer, guide, winding waste edge, roll shearing machine, and material discharge, all these configurations and designs are based on the customer's processing needs, factory floor space and output requirements. KINGREAL SLITTING customizes and designs suitable metal slitting line.

The core advantage of metal slitting machine equipment lies in the accuracy of slitting. The repeatability of shearing accuracy of high-precision shearing equipment is very important. It represents the overall processing accuracy of the metal slitting machine production line. Its influencing factors are not only the processing accuracy of the shearing tool but also whether the basic parameters are reasonable when selecting the equipment.

Common steel slitting machine classifications include:

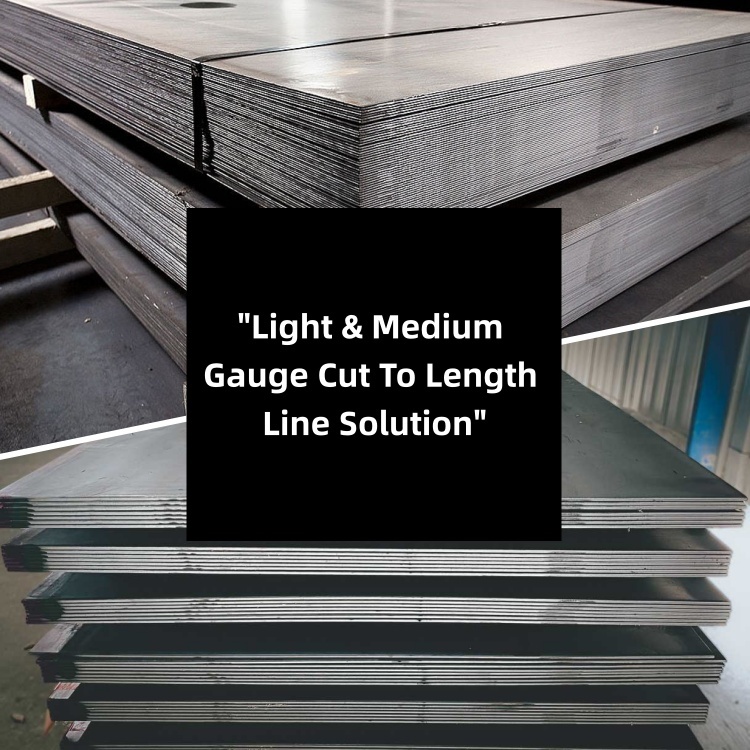

According to the thickness of the coil that can be slitting, it can be divided into light gauge slitting line (processing thickness 0.2-3.0mm) and heavy gauge slitting line (processing thickness 6.0-16.0mm). According to the slitting metal material, it can be divided into copper coil slitting line, stainless steel slitting line, cold roller slitting line, silicon steel slitting line, and tinplate slitting line. According to the degree of automation, it can be divided into fully automatic metal slitting line and semi-automatic steel slitting line.