"KINGREAL SLITTING is a professional automatic cut to length machine manufacturer, specializing in the design, development, and manufacture of automatic cut to length lines, providing customers with comprehensive automatic cut to length machine manufacturing solutions. KINGREAL SLITTING automatic cut to length lines meet the standards and requirements of markets worldwide, offering customers high-speed, high-precision automatic cut to length machines."

Support for Automatic Cut to Length Line

KINGREAL SLITTING offers automatic cut to length machine maintenance and parts replacement services. If a customer's automatic cut to length line experiences problems such as blade wear, simply contact KINGREAL SLITTING. Based on the customer's particular automatic cut to length machine model, KINGREAL SLITTING will immediately issue a spare part order, therefore guaranteeing continuous manufacturing.

Furthermore, KINGREAL SLITTING can send qualified experts to install the recently purchased automatic cut to length line upon arrival at the customer’s location. Along with teaching customers how to run the automatic cut to length machine correctly, these engineers offer regular maintenance training to guarantee long-term, consistent performance. If an automatic cut to length line malfunctions during use, customers can contact KINGREAL SLITTING service team immediately.

KINGREAL SLITTING engineers will conduct online or offline troubleshooting and provide specific solutions to maintain customer production efficiency. To ensure timely answers to customer questions regarding the automatic cut to length machine, KINGREAL SLITTING offers a 24-hour online customer service team ready to provide professional and detailed answers, ensuring smooth and efficient production for every customer.

●Technological Innovations in Automatic Cut to Length Lines

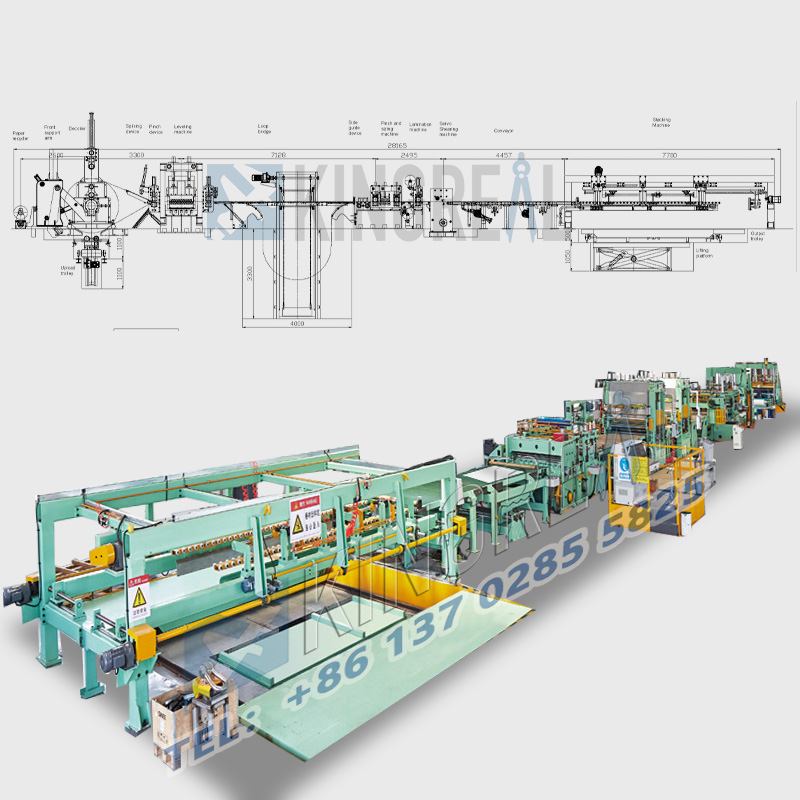

In terms of technological innovation, KINGREAL SLITTING offers a variety of automatic cut to length machines with varying parameters and performance. Whether in cutting capacity, production efficiency, or automation, KINGREAL SLITTING automatic cut to length lines are sure to satisfy customers. KINGREAL SLITTING fully automatic cut to length machine design significantly improves production efficiency. KINGREAL SLITTING customizes each automatic cut to length line based on customer drawings and actual production requirements, including material width, thickness, weight, metal material, precision requirements, and speed requirements. This customized service ensures that KINGREAL SLITTING automatic cut to length machines are perfectly suited to the processing needs of various metal materials.

What Kind of Automatic Cut to Length Lines Does KINGREAL SLITTING Offer?

1. Light Gauge Cut To Length Line

Light Gauge Cut To Length Lines are designed specifically for processing thin, lightweight metal materials. Light Gauge Cut To Length Line are suitable for processing a variety of metals with thicknesses ranging from 0.2-3mm, including pre-coated, galvanized, and hot-rolled materials. Built with user comfort in mind, these Light Gauge Cut To Length Lines have a simple control system that enables operators to rapidly master and effectively finish cutting tasks. The high-precision cutting features of the Light Gauge Cut To Length Line guarantee the quality of every sheet metal cut during operation. For sectors with strict standards for material look and measurements, this is especially crucial. Moreover, the Light Gauge Cut To Length Line's adaptability lets it meet various material processing demands, so enabling customers to easily modify based on their particular requirements, the cutting parameters.

The high-precision cutting features of the Light Gauge Cut To Length Line guarantee the quality of every sheet metal cut during operation. This is especially crucial for sectors with exacting standards for material surface and dimensions. Moreover, the flexibility of the Light Gauge Cut To Length Line enables it to meet the processing demands of many materials, therefore enabling consumers to readily change their settings. the particular needs they have.

2. Heavy Gauge Cut To Length Line

Designed for processing metal materials with thicknesses varying from 6 to 25mm, Heavy Gauge Cut To Length Lines guarantee exact cutting. Designed with the difficulties thick materials present in mind, this Heavy Gauge Cut To Length Line uses high-hardness blades, so guaranteeing consistent cutting performance even under heavy loading. Commonly found in heavy industry, construction, shipbuilding, and other sectors where material strength and cutting accuracy are very high demanded, Heavy Gauge Cut To Length Lines.

Users can change the shearing speed and pressure depending on the material characteristics during operation to guarantee best cutting results. KINGREAL SLITTING has added modern automation technology into the Heavy Gauge Cut To Length Line to boost manufacturing efficiency, hence enabling consumers to simply control the whole shearing undergo via a computer control system.

3. Medium Gauge Cut To Length Line

The Medium Gauge Cut To Length Line, launched by KINGREAL SLITTING in response to market demand, is specifically designed to process coils with thicknesses ranging from 0.3 to 6 mm. This Medium Gauge Cut To Length Line fills the gap between Light Gauge Cut To Length Line and Heavy Gauge Cut To Length Lines and is widely used in industries such as automotive, home appliances, and electronics. The flexibility of the Medium Gauge Cut To Length Line enables it to adapt to a wide range of material processing needs, efficiently processing different types of metal materials to meet the diverse needs of customers. The Medium Gauge Cut To Length Line is designed with meticulous attention to cutting precision and efficiency. Its highly efficient shearing system enables rapid completion of high-volume production while ensuring high-quality cuts for every piece of material. Furthermore, the Medium Gauge Cut To Length Line is user-friendly, allowing users to quickly adjust cutting parameters through simple settings.

4. High Speed Cut to Length Line

KINGREAL SLITTING high speed cut to length machine is specifically designed to meet the demands of high-efficiency production, with a maximum speed of 80 m/min. This high speed cut to length machine can quickly process a wide range of plate sizes and is widely used in industrial production requiring high output. KINGREAL SLITTING engineers will configure the high speed cut to length machine with a variety of shearing systems, including fly shearing, rotary shearing, and swing shearing, based on the customer's specific needs to achieve optimal production results.

During operation, the high speed cut to length machine's efficient cutting capacity and precise control system ensure the highest possible cut accuracy for every piece of material. This is particularly important for industries requiring high precision and efficiency, such as automotive and aerospace. KINGREAL SLITTING also offers a comprehensive range of automation options, allowing users to select the appropriate automation configuration to optimize their production processes. High speed cut to length machines are designed with operational safety and easy maintenance in mind, and can be equipped with protective devices to ensure operator safety. Regarding automatic cut to length line maintenance, users can easily perform daily inspections and maintenance to ensure long-term stable operation.

5. Stacker for Automatic Cut to Length Line

To improve the efficiency of fully automatic cut to length lines, KINGREAL SLITTING equips them with a stacker. This stacker automatically stacks metal sheets, completely replacing traditional manual sorting methods and significantly improving production efficiency. The stacker design not only improves efficiency but also reduces operator workload and enhances production safety.

KINGREAL SLITTING also offers dual stackers configurations to ensure efficient production throughout the entire process, further increasing overall production capacity.

6. Dual Levelers for Automatic Cut to Length Machine

KINGREAL SLITTING typically equips automatic cut to length lines with one leveler to ensure material flatness before cutting. For customers with higher requirements for sheet flatness, KINGREAL SLITTING can also equip the automatic cut to length machine with two levelers, achieving a two-step leveling process to further enhance material flatness. The double-leveler design allows for more thorough leveling of the material after uncoiling, ensuring it reaches optimal flatness before shearing. This is particularly important for industries such as automotive and aerospace, where material flatness is paramount.

Are You Ready for a New Automatic Cut to Length Line?

In today's highly competitive market, selecting a high-performance automatic cut to length machine is crucial for improving production efficiency and product quality. KINGREAL SLITTING, with its high-quality automatic cut to length machines and first-class customer service, offers comprehensive support to ensure you have the best metalworking experience.

From setup to operation, from ordering to delivery, KINGREAL SLITTING will assist you enhance throughout the automatic cut to length machine procedure. With your new automatic cut to length line, efficiency and production are improved. KINGREAL SLITTING knows that the performance of an automatic cut to length machine directly affects your output. Commits to offering the best automatic cut to length line solutions for efficiency and profitability.

Contact KINGREAL SLITTING today for a detailed quote and more information about automatic cut to length machines. Whether you need a Light Gauge Cut To Length Line, a Heavy Gauge Cut To Length Line, a High Speed Cut to Length Line or other automatic cut to length machines, KINGREAL SLITTING can provide you with a satisfactory solution.