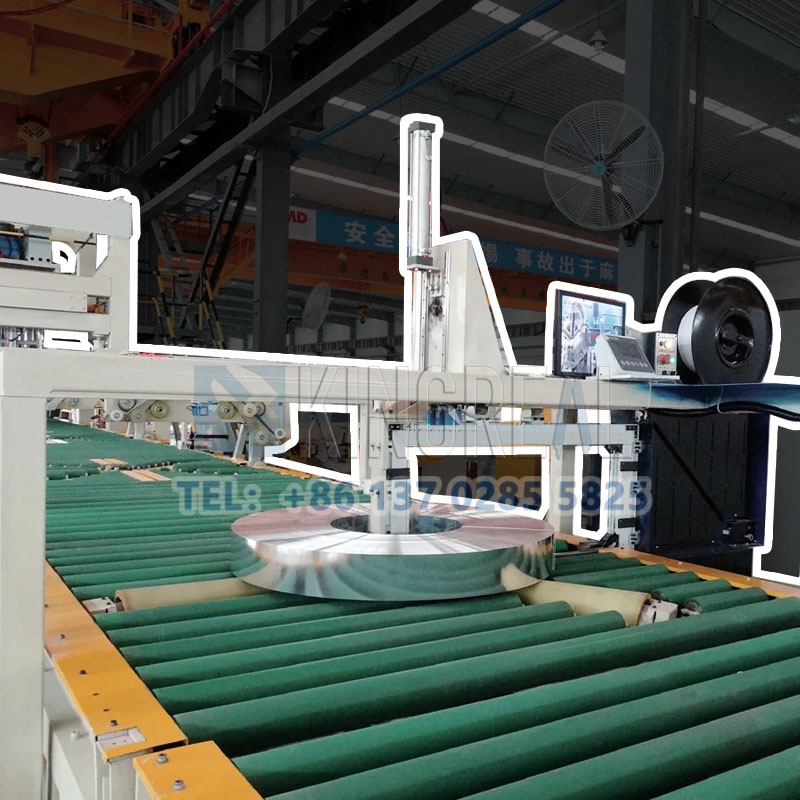

"To improve metal coil slitting line and enhance the automation level of the entire process, KINGREAL SLITTING specifically designed a coil packing machine. This automated coil packaging line can efficiently bundle and package cut narrow strips of metal.

This coil packing machine is actually a modular production line, consisting of automatic pick-up, bundling, and stacking components, primarily for handling each coil. Specifically, these conveyor-type coil packaging lines are responsible for radially bundling and stacking the coils to form neat bundles. These bundles are then placed on pallets for weighing and labeling, ready for subsequent production or transportation stages."

Material Requirements for Coil Packing Machine

Material adaptability is extremely important for the coil packing machine. KINGREAL SLITTING coil packaging line can handle strip weights up to 6000 kg and bundle weights up to 12000 kg. Its bundling strap length ranges from 500 to 2200 mm, and the stacking length ranges from 200 to 6000 kg. This coil packing machine can package all metal materials that metal coil slitting lines can process, including cold-rolled, hot-rolled, galvanized steel, pre-painted steel, stainless steel, aluminum, and other metals. This flexibility allows the coil packing machine to be widely used in various industrial sectors.

Complete Metal Slitting Solutions

To meet industrial needs for cutting steel and other ultra-high-strength material coils, KINGREAL SLITTING offers high-performance metal coil slitting lines. These metal coil slitting lines can longitudinally cut coils of various thicknesses, from the thinnest to the thickest, into narrow strips of the required width for the project. The cut metal strips undergo further processing on KINGREAL SLITTING coil packaging line, including radial bundling, circumferential bundling, weighing, packaging, and stacking. This integrated approach effectively protects the coils and standardizes processing, ensuring the safety and integrity of products during transportation and storage.

Furthermore, connecting a metal coil slitting line to an automated coil packing machine can replace 5-10 human operators, significantly reducing reliance on labor and lowering labor costs while increasing production efficiency.

Benefits of Coil Packaging Line for Metal Strips

Automated coil packing machines provide a one-stop service from roll material to packaging and stacking, improving the overall efficiency and safety of the production line. By minimizing manual operation, the baling system not only saves labor costs but also reduces losses caused by human error. The efficient operation of the coil packaging line is made possible by several precision components.

1)Cross-arm for coil packing machine

Coil packaging lines can be equipped with cross-arm components, featuring high load capacity and robust structural design. Their core function is to automate the loading, unloading, and transfer of roll materials (such as steel coils, copper coils, and aluminum coils). During full roll loading, the cross-arm directly connects to the vertical packaging line to complete the gripping and feeding of the entire coil of material, ensuring a supply of roll material for packaging to the coil packing machine.

During slitting and transfer, the cross-arm lifts the slitting-processed metal coil to the loading RGV (Automated Guided Vehicle) of the baling line in one go, achieving efficient transfer, reducing the burden of heavy manual labor on workers, and improving work efficiency.

2)Automatic coil tilter station for coil packaging line

Automatic coil tilter stations are used for automatically separating and extracting steel coils. Their hydraulic lifting heads, with varying widths, effectively protect the steel strips and reduce damage during handling. Coil tilter stations allow for easy handling of heavy materials, increasing operational safety and continuity.

3)Coil strapping machine for coil packing machine

Coil strapping machines can connect to conveyor workbenches to form complete production lines. The tension of the wrapping tape is adjustable, and the ring speed and roller speed can be adjusted via inverters and frequency converters to ensure the stability and uniformity of each package, guaranteeing that the packaging quality meets customer requirements.

4)Stacker for coil packaging line

Finally, stackers are specifically designed to move packaged steel strips one by one from a conveyor to pallets. As a mechanical lifting platform, stackers operate smoothly and quickly, primarily consisting of a gantry-type moving mechanism. This design makes stacking more efficient and faster. Furthermore, it reduces the inefficiency of traditional manual stacking, improving overall production efficiency.

Considerations for Choosing a Coil Packing Machine

Before selecting a coil packaging line, it's crucial to fully understand the product characteristics and production line parameters, as these directly impact packaging efficiency and quality.

1) Coil size range for coil packaging line

The size of the produced coils will affect the overall production line planning, including the inner diameter, outer diameter, width, and weight range. These parameters relate to equipment compatibility and the final packaging effect.

2) Capacity requirements for coil packaging line

Before selecting a suitable coil packing machine, the factory's daily capacity should also be considered. For example, the daily or hourly coil packaging volume required, including minimum and maximum output requirements, determines the specifications and functional configuration of the coil packing machine.

3) Product type for coil packaging line

Different types of coils, such as cold-rolled coils, hot-rolled coils, stainless steel coils, and copper coils, require different packaging technologies and equipment configurations. Therefore, understanding which types of coils the factory needs to package is particularly important.

4) Packaging material requirements for coil packaging line

Finally, the selection of the primary packaging materials is also critical. For example, different materials such as composite paper, woven fabric, plastic film, and PE film will affect the performance of the coil packing machine. Therefore, choosing the right packaging material is especially important when configuring a coil packaging line.

Contact KINGREAL SLITTING now to learn more about metal coil slitting line and coil packing machine solutions.