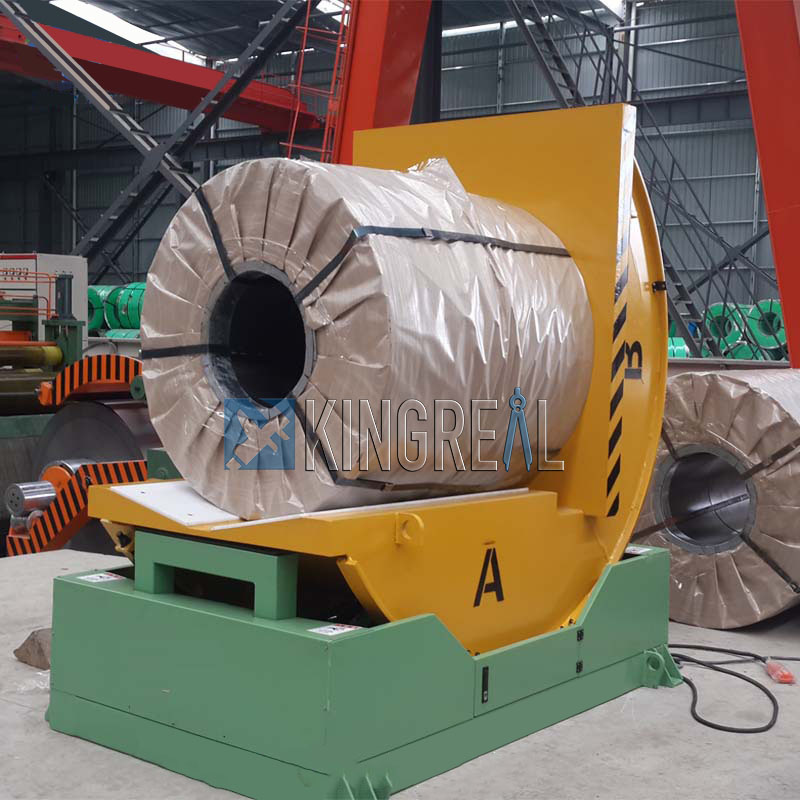

Description of coil tilter station

The coil tilter station, also known as coil upenders, is a device used to safely and efficiently tilt heavy coils. It can tilt the coil to 90°or 180°, ensuring a smooth transition of the coil to the metal coil slitter for subsequent slitting operations. The coil turnover machine is designed to be rugged and high-precision, designed to minimize manual operation, improve operational safety, optimize workflow in industries such as steel processing and manufacturing, ensure reliable performance and reduce downtime.

Main components of coil upenders

The main components of the coil turnover machine include:

- Adjustable narrow coil support arm: used to support coils of different sizes and ensure their stability during the tilting process.

- Sturdy V-shaped bracket: provides support for the coil to prevent it from sliding during operation.

- 180 degree rotating base: allows the machine to flexibly flip the coil to the desired angle.

- Guide roller support: helps the coil move smoothly, reducing friction and wear.

- Powered sliding V-shaped bracket: used to easily remove the tilted coil.

- Heavy steel structure: ensures the durability and stability of the equipment.

Advantages of coil turnover machine

1. Using with metal slitting machine

One of the major advantages of coil upenders is that it can be used with metal slitting machine to achieve high automation of the slitting process. After ensuring the smooth transition of the coil through the coil upenders, it can be smoothly fed into the coil slitting machine for slitting operation. The automation of this process not only improves production efficiency, but also reduces the errors and risks caused by human operation. Through the effective combination with the silicone steel slitting machine, the coil upenders not only optimizes the workflow, but also provides strong support for the sustainable development of the enterprise.

KINGREAL SLITTING can provide customers with coil turnover machines and different types of metal slitting machines, such as aluminum slitting machines,copper slitting machines, hot-rolled slitting machines, cold-rolled slitting machines, etc. And according to the actual production needs of customers, mini slitting machines, belt tension coil slitting machines, light gauge slitting machines, and dual slitter head slitting machines can also be customized for customers.

2. Improve material handling efficiency

Automatic coil upenders greatly improves the efficiency of material handling. Traditional coil handling methods often rely on forklifts or manual handling, which can lead to delays and inconsistent performance. Automatic coil upenders, on the other hand, can flip heavy coils in seconds through precise mechanical operations while maintaining the structural integrity of the coil.

This efficiency improvement translates directly into increased productivity. Manufacturing plants equipped with automatic coil turnover machine report a 35% reduction in operational delays. According to a recent industry study, this improvement is particularly important in fast-paced industries such as automotive and construction, where timely delivery of materials is key to ensuring a smooth production process.

3. Reduced safety hazards

Manual coil handling presents a high safety risk. Workers are often faced with sharp edges and unstable equipment when handling heavy loads. Automatic coil turnover machine eliminate many safety hazards by replacing manual intervention with a fully controlled mechanical system. According to statistics, the use of these coil upenders has reduced workplace injury rates by an average of 40%, so they are considered an important investment in employee safety.

4. High automation

The heart of the automatic coil upenders lies in its advanced control system. These coil turnover machines are able to perform precise operations through the synergy of sensors and hydraulic mechanisms. Not only can these systems handle heavy coils up to several tons, they can also significantly reduce energy consumption and reduce the carbon footprint of the manufacturing process. For example, a 5-ton coil can be dumped in 30 seconds, fully demonstrating the power and efficiency of these machines.

5. Cost-Benefit Analysis

Although automatic coil upenders require a higher upfront investment, the cost savings in the long run often outweigh the initial expenditure. These coil turnover machines will significantly improve the return on investment by reducing labor costs, reducing workplace accidents, and improving productivity. Many companies have found that although the initial investment is higher, the efficient operation and low failure rate of the coil upenders make it very cost-effective in long-term operations.

6. Monitoring and Safety Mechanisms

Modern coil upenders are usually equipped with a series of monitoring systems, including weight sensors, motion detectors and emergency stop functions. These safety mechanisms ensure smooth operation while providing real-time feedback to the operator. With an emergency stop function, the coil upenders can immediately stop operation when an abnormal situation occurs, effectively preventing accidents. In addition, load balancing sensors ensure even weight distribution during the tipping process, reducing the risk of coil damage. Proximity detectors are used to detect people or obstacles near the operating area, further improving worker safety.

These features make the automaticcoil turnover machine a reliable and safe device for industrial environments.

KINGREAL SLITTING is a professional manufacturer ofcoil upenders and coil slitting machines, striving to provide customers with complete coil solutions. If you are interested in these machines, welcome to consult KINGREAL, we will send the most professional staff to serve you throughout the process!