Metal slitting line is an important part of steel slitting, a steel manufacturing process that slits steel coils into lengths and widths specified by the final application. The process requires a metal slitting machine equipped with decoilers, slitters and recoilers to produce the final product.

Process of Metal Slitting Line

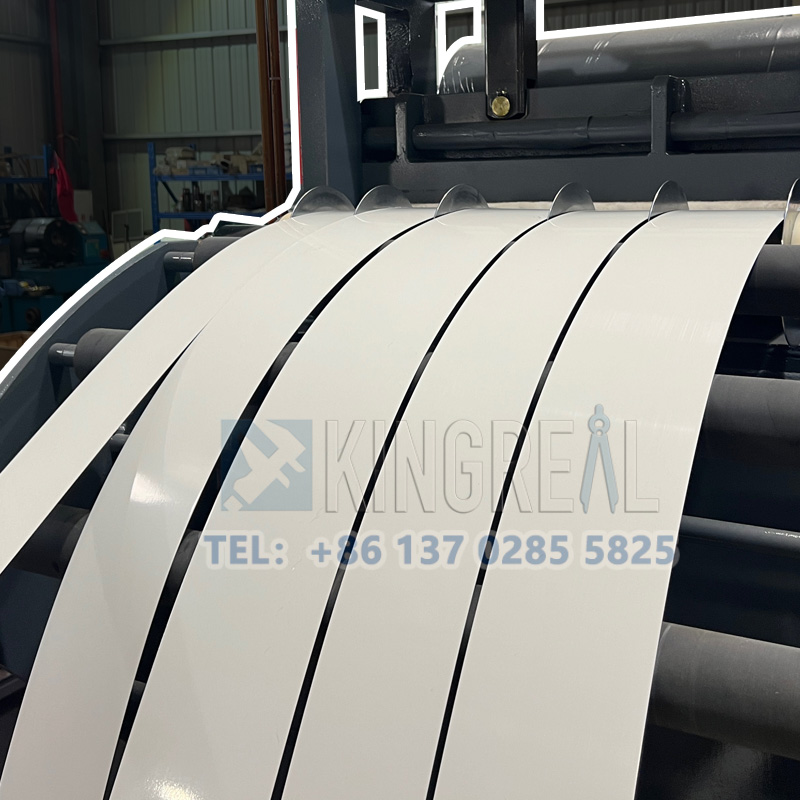

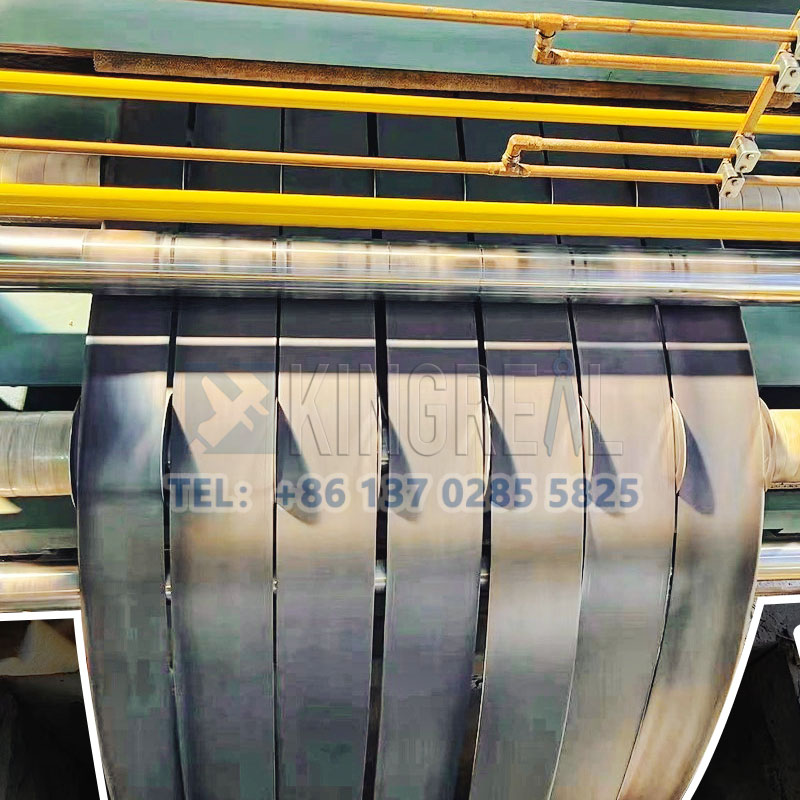

The operation of a metal slitting machine mainly starts with an unprocessed steel coil, passes through the slitting process, and finally enters the recoiler, which cuts the original large coil into three perfectly slit steel coils.

The operator feeds the steel coil into the drum of the decoiler. The decoiler unwinds the main coil and feeds it into the slitting head, where the steel is slit into narrow strips (multi-strands) by a rotating knife. The operator then checks each multi-strand to ensure that its thickness and edge condition meet the specifications. After that, the multi-strand will pass through an annular groove to ensure that the slit material is stress-free and bend-free. After that, each multi-strand is bundled and packaged according to the specific requirements of the customer.

This process requires precise processing. KINGREAL SLITTING uses rugged precision metal slitting machines equipped with advanced software, tooling and hardware technology. This helps provide customers with streamlined production processes and shortened delivery times. After the metal slitting machine is manufactured, the KINGREAL SLITTING team will thoroughly check the calibration of the metal slitting line to reduce scrap and lower total costs.

Parameters of Metal Slitting Machine

KINGREAL SLITTING metal slitting lines are personalized metal slitting machine manufacturing solutions designed by staff for customers based on actual production needs of customers and combined with drawings. Therefore, the metal slitting line parameters provided by KINGREAL SLITTING to customers are different. The following metal slitting line parameters are for reference only. If you have special requirements for the parameters of the metal slitting line, please come to consult KINGREAL SLITTING!

| Light gauge coil slitting line | Medium gauge coil slitting line | Heavy gauge coil slitting line | |

| Cutting System | Loop-Double Loop | Pull Assist-Loop | Pull Through-Slitter Assist |

| Max Thickness | 0.150‘’ | 0.312‘’ | 0.750‘’ |

| Max Width | 72‘’ | 84‘’ | 96‘’ |

| Max Weight | 35T | 40T | 50T |

| Max Speed | 2000 ft/min | 1000 ft/min | 300 ft/min |

Different Metal Slitting Line Manufacturing Solutions

In the metal processing industry, metal slitting lines are important equipment for cutting large coils of metal materials into the required width. KINGREAL SLITTING has designed three efficient metal slitting machines based on the different needs of customers in processing metal coil thickness, namely light duty coil slitting machines, medium duty coil slitting machines and heavy duty coil slitting machines. These metal slitting lines not only meet the cutting needs of materials of different thicknesses, but also have the characteristics of high production efficiency and flexibility.

Light duty coil slitting machine The light duty coil slitting machine is designed for processing metal coils with a thickness of 0.2-3 mm. This type of light duty coil slitting machine is very suitable for processing thin metal materials such as aluminum, galvanized steel and stainless steel. The main features of the light duty coil slitting machine include: High cutting precision guarantees the quality of the finished product by using an advanced blade design and accurate control system the light duty coil slitting machine may reach up to ±0.1 mm. Quick switching: The light duty coil slitting machine has a basic tool replacement mechanism that lets the operator finish blade replacement in little time, hence much reducing the production preparation time. The modular design of the light duty coil slitting machine lets clients tailor the configuration to fit their specific needs, including the addition of more knife groups or automated systems to increase production flexibility. For the demands of the automotive, home appliance, and building sectors, light duty coil slitting machines are especially well suited. Its use potential is wide since demand for light materials is growing. |  |

Medium duty coil slitting machine Suitable for medium-thickness metal processing requirements, the Medium duty coil slitting machine is designed for processing metal coils with a thickness of 36 mm. This kind of Medium duty coil slitting machine is used in the production of mid-sized structural components and mechanical parts. Among its primary characteristics are: Increased cutting capacity: The Medium duty coil slitting machine has a more strong motor and knife that can readily process heavier metal items to guarantee output quality and efficiency. Modern automated control system: To boost production efficiency, the Medium duty coil slitting machine incorporates a modern automated control system that may automatically change cutting speed and tension according to various manufacturing requirements. Strength and longevity: The Medium duty coil slitting machine is built with strength and durability in mind and employs high-strength materials and constructions to let it sustain stable operation under heavy weights. Medium duty coil slitting machines are rather used in building materials, heavy equipment, and other industrial sectors and can satisfy consumers' varied need for medium-thickness metallic materials. |  |

Heavy duty coil slitting machines Heavy duty coil slitting machines are meant to handle metal coils ranging in thickness between 6-16 mm and are appropriate for intensive metal processing. Mostly represented in: Heavy duty blades and strong motors enable the Heavy Duty Coil Slitting Machine to effectively process thick and heavy materials, hence guaranteeing stability during the cutting operation. The heat produced cutting thick plates might impact the cutting accuracy if the cooling system is optimized. To guarantee that the blade has a proper temperature under heavy stress and hence lengthens the lifespan of the knife, the Heavy duty coil slitting machine includes an effective cooling system. Modular architecture is also used in the Heavy duty coil slitting machine. To increase the adaptability and production efficiency of the apparatus, consumers may install several cutting modules as necessary. Meeting the demands of high-strength and high-precision metal processing, heavy-duty coil slitting machines are extensively used in sectors including shipbuilding, steel manufacture and heavy machinery. |  |

Advantages of KINGREAL SLITTING Metal Slitting Line

KINGREAL SLITTING metal slitting machine not only excels in processing metal coils of different thicknesses, but also has the following advantages:

1.More production capacity

With effective production capacity, KINGREAL SLITTING metal slitting line is meant to handle enormous numbers of materials in superior quality finished product silos. Its sophisticated electrical system automates tasks typically carried out only by operators, therefore improving general performance. This automation not only lowers labor expenses but also raises output efficiency, enabling businesses to swiftly satisfy market demands and shorten production cycles.

2.Improved flexibility

Flexibility is essential in contemporary manufacturing. The modular design of KINGREAL SLITTING metal slitting machine allows it to be modified mechanically and electronically, hence improving its company by becoming a brand-new factory fit to process various coil diameters and material kinds. This flexibility allows businesses to swiftly adapt metal slitting lines depending on market developments and satisfy consumer variety.

3. Dependability and longevity

Designed for strength and durability, KINGREAL SLITTING metal slitting line uses high-strength materials and a dependable structural design to guarantee steady performance even under heavy loads. The low maintenance demands of the metal slitting machine let businesses cut operating expenses and minimize downtime. Furthermore, KINGREAL SLITTING metal slitting machines use common market parts, therefore easing future maintenance and replacement