Silicon steel is an important electrical material, widely used in power equipment, transformers, motors and other fields, and is favored for its excellent magnetic permeability and low loss characteristics. In the production process of silicon steel, the transformer core cutting machine plays a key role, responsible for longitudinally cutting large rolls of silicon steel strips into narrow strips of the required width to meet the needs of different equipment.

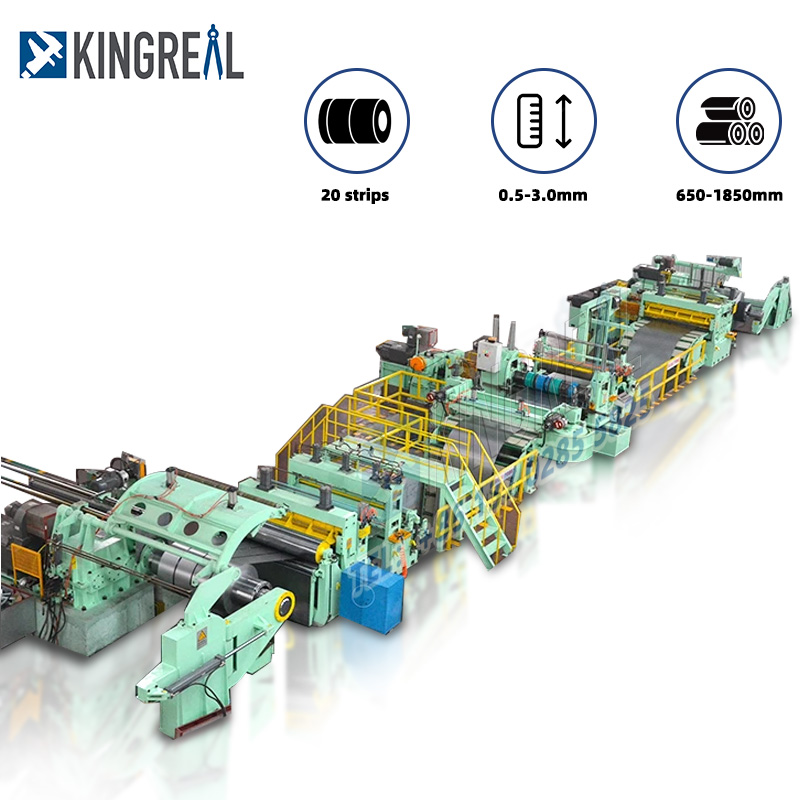

Compared with aluminum slitter, steel coil slitting machine, hot rolled slitter, cold rolled slitter machine and stainless steel slitting machine, silicon steel coil slitting lines face greater challenges in manufacturing and operation. These challenges not only affect the quality and performance of the products, but also determine production efficiency and cost. Therefore, in-depth exploration of the challenges faced by transformer core cutting machines is of great significance to improving production processes and product quality.

Challenges Faced by Silicon Steel Coil Slitting Lines

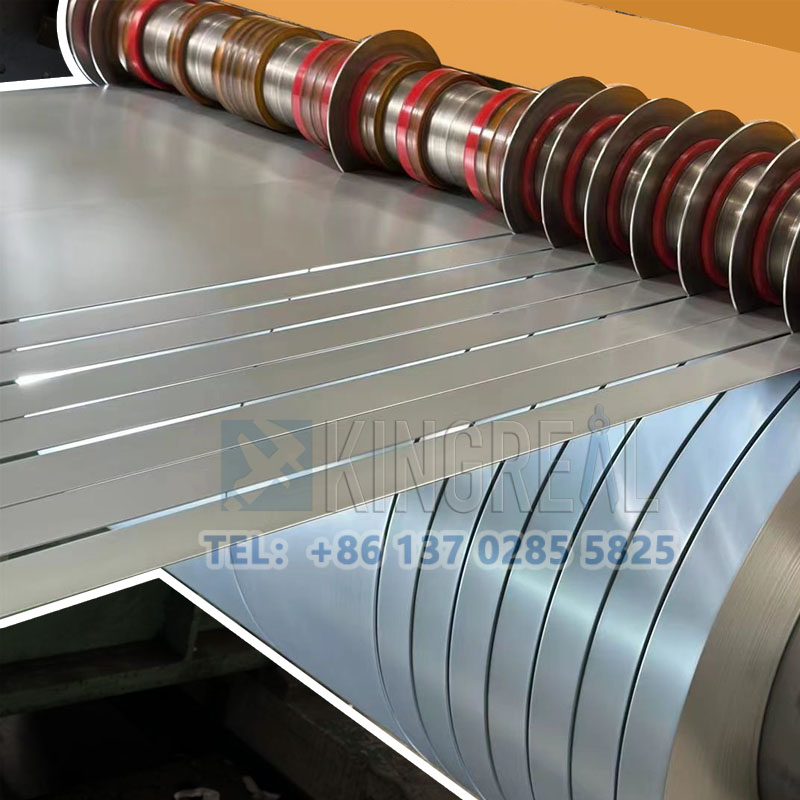

1. Control of surface quality

The surface quality of silicon steel strips directly affects their magnetic permeability and loss characteristics. During the processing process, the surface of the silicon steel strip must be flat and smooth, without defects such as scratches, dents, oxidation and oil stains. Surface defects not only lead to increased energy loss, but may also affect the overall performance of transformers and motors. In order to ensure surface quality, the transformer core cutting machine needs to use high-precision tools in design and manufacturing, and control the cutting speed and pressure.

2. Maintaining edge straightness

The edges of silicon steel strips should be kept straight, and any obvious curling, burrs and cracks may cause subsequent processing and forming problems. Edge straightness has an important influence on the processing and forming of silicon steel strips, especially during welding and lamination. Therefore, the silicon steel coil slitting line must have a high-precision guiding and cutting system to ensure that the straightness of the edges is effectively controlled during the longitudinal shearing process.

3. Dimensional accuracy requirements

The silicon steel strip after transformer core cutting machine must meet the dimensional accuracy required by the customer, including requirements in width, thickness and length. The dimensional deviation should be controlled within a reasonable range to ensure that the product can meet the design requirements. Compared with metal slitting machines of other materials, silicon steel coil slitting lines have more stringent requirements in terms of dimensional accuracy, which requires the equipment to have higher processing accuracy and automatic control capabilities.

4. The particularity of material properties

The physical and chemical properties of silicon steel make it more complicated during processing. Silicon steel is usually thin and fragile, and it is easy to deform or break during the cutting process. This requires that the transformer core cutting machine must adopt appropriate processing parameters and cutting methods when operating to reduce damage to the material.

Advantages of Transformer Core Cutting Machines

Although silicon steel coil slitting lines face many challenges, their advantages in modern production cannot be ignored:

1. High efficiency

Modern transformer core cutting machines can achieve high-speed slitting and longitudinal shearing to improve production efficiency. Compared with traditional equipment, its production capacity has increased by 30%, effectively shortening the production cycle and reducing production costs. This highly efficient production method not only meets market demand, but also enhances the competitiveness of enterprises.

2. Intelligent control

The silicon steel coil slitting line is equipped with an advanced intelligent control system that can monitor and adjust various parameters in the production process in real time. This intelligent operation method ensures stable operation and efficient production of the transformer core cutting machine. The operation is simple and convenient, which reduces the tediousness of manual operation and improves work efficiency.

3. Energy saving and environmental protection

Modern silicon steel coil slitting line adopts advanced energy-saving technology, which can effectively reduce energy consumption and emissions and meet environmental protection requirements. In the production process, the generation of waste and exhaust gas is reduced, the impact on the environment is reduced, and the concept of sustainable development is reflected. This energy-saving and environmentally friendly feature enables the silicon steel coil slitting line to meet production needs while also meeting the sustainable development goals of society.

4. Reliable and stable

Transformer core cutting machines use high-quality materials and components, and undergo strict quality control and testing to ensure the reliability and stability of the silicon steel coil slitting line. During long-term operation, the transformer core cutting machine can maintain an efficient working state, reduce failures and downtime, and further improve production efficiency. This reliability is especially important for large-scale production because it is directly related to the continuity and economic benefits of the production line.

Strategies to cope with challenges

Facing the challenges of silicon steel coil slitting lines, enterprises can adopt the following strategies to improve the performance and production efficiency of transformer core cutting machine:

1. Use high-end materials and technologies

In order to improve the stability and precision of transformer core cutting machines, KINGREAL SLITTING chooses high-end materials and advanced technologies to manufacture equipment. For example, the use of high-strength alloy steel cutters can reduce wear and ensure that the cutters maintain good cutting performance after long-term use.

2. Strengthen equipment maintenance and care

KINGREAL SLITTING recommends that customers regularly maintain and care for silicon steel coil slitting lines, which can effectively extend the service life of the equipment and maintain its efficient working state. Customers should also establish a complete transformer core cutting machine maintenance system, regularly check the operation of the tool, transmission system and control system, and promptly discover and solve potential problems.

3. Continuous technological innovation

Continuous technological innovation is the key to improving the performance of silicon steel coil slitting lines. KINGREAL SLITTING has been encouraging the R&D team to innovate technology and explore more efficient cutting methods and intelligent control algorithms to adapt to changes in market demand.

4. Strengthen employee training

The skill level of operators directly affects the operating efficiency and product quality of transformer core cutting machines. KINGREAL SLITTING recommends that customers regularly train their employees to improve their operating skills and ability to deal with problems to ensure efficient operation of the silicon steel coil slitting line.