Brass coil slitting machine is an industrial equipment used to slit large rolls of brass metal coils into high-precision narrow strips. It cuts according to the parameters set by the customer, ensuring that the surface of the slit product is smooth and burr-free.

Brass coil slitting lines are widely used in many countries around the world, such as India, Indonesia, Malaysia, the Philippines and the United States. This article will explore the construction, working principle, main components and application of brass coil slitting machines in various industries.

1. What is a Brass Coil Slitting Machine?

Brass coil slitting line is a special equipment used to cut large rolls of brass metal coils into precise widths. It not only provides efficient production capacity, but also ensures excellent edge quality after cutting. The importance of brass coil slitting machines is reflected in the following aspects:

Why is Copper Coil Slitting Line so Important?

1) High-precision cutting

Copper coil slitting machines can accurately cut brass narrow strips of the required size according to the specific needs of customers. This precision is essential for subsequent processing to ensure that the parts meet strict industry standards.

2) Improve production efficiency

By automating the cutting process, the brass coil slitting line greatly improves production efficiency and reduces labor costs. The copper coil slitting machine can run continuously to ensure fast delivery.

3) Reduce material waste

Precise settings and efficient cutting processes can minimize material waste and save costs for enterprises.

4) Wide application

Brass coil slitting lines play an important role in multiple industries, including electronics, automobiles, and construction. This makes it an indispensable part of modern manufacturing.

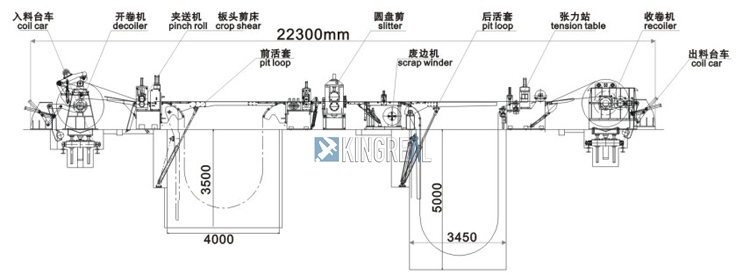

2. Main Components of Brass Coil Slitting Lines

Brass coil slitting machines are composed of several key components, each of which plays an important role in the entire cutting process:

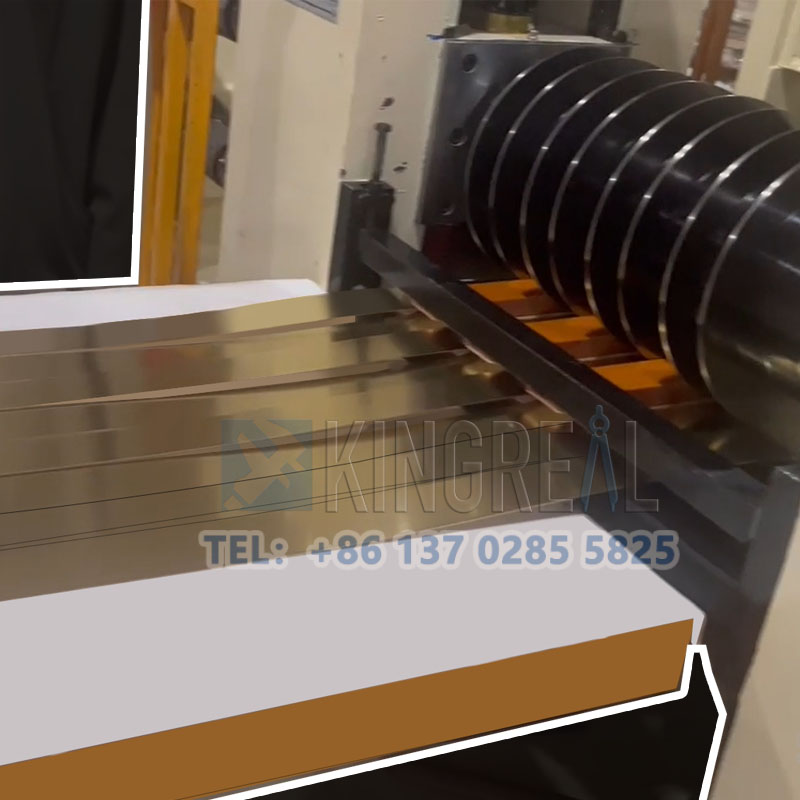

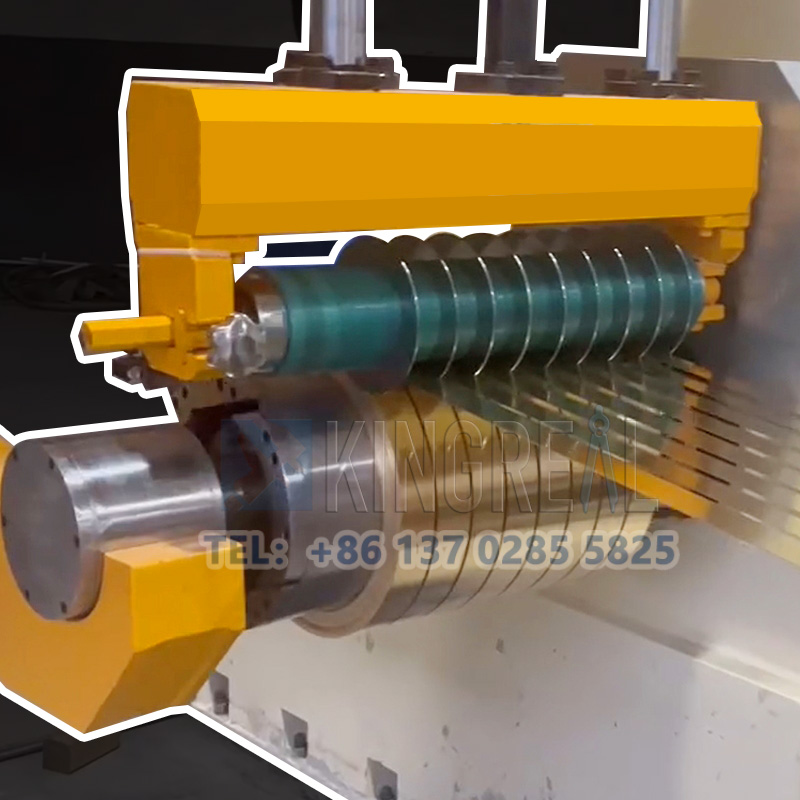

(1) Cutter (slitting blade) for brass coil slitting line

The hardened and precision-ground rotary cutter is the key to achieving clean and accurate cuts. The material, sharpness, and alignment of the blade directly affect the quality and dimensional consistency of the slitting edge. Choosing a high-quality cutter can ensure stable cutting performance over a long period of time.

(2) Mandrel for brass coil slitting machine

The mandrel is used to fix and rotate the cutter. Precise alignment is essential, and any vibration or imbalance can result in poor edge condition or dimensional deviation. Therefore, the quality and design of the mandrel directly affect the cutting effect.

(3) Shims for brass coil slitting line

Shims are used to position the knives and maintain precise gaps between the knives. Proper spacing is essential to achieve tight width tolerances and avoid material waste due to improper gaps.

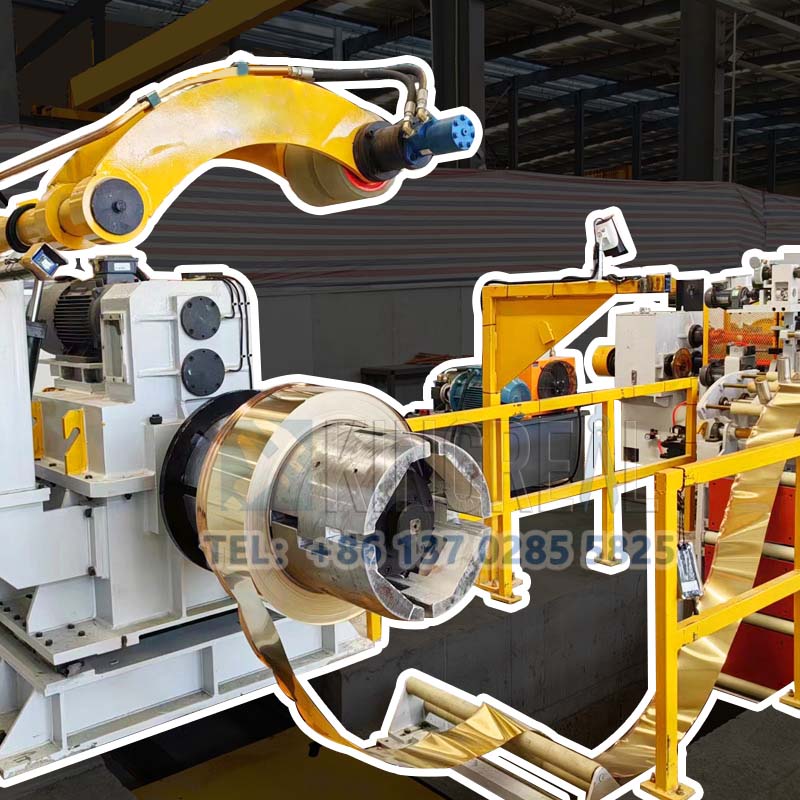

(4) Recoilers for brass coil slitting machine

The recoilers wind the slit strip into coils. A reliable winder can maintain proper tension to ensure neat winding and avoid damaging the edges. The stability of the winding directly affects the quality of the final product.

(5) Tension system for brass coil slitting line

Proper tension is essential to prevent telescoping, burrs or edge waves. The tension system ensures a smooth and uniform winding process and guarantees the quality of the slit product.

3. Working Principle of Brass Coil Slitting Machine

The working process of the brass coil slitting line can be divided into several steps:

(1) Metal coil loading

The metal coil is installed on the decoiler and prepared for processing. This step requires the operator to confirm the specifications and position of the coil to ensure the smooth progress of subsequent operations.

(2) Setting up and calibrating the brass coil slitting machine

According to the required slitting width, the knives and shims are precisely arranged on the knife shaft. Precise settings minimize scrap and achieve consistent slitting results.

(3) Slitting

The coil is fed through the slitter and accurately cut into narrower strips at high speed. The operator monitors the slitting process throughout to ensure that the calibration and performance of the cutter remain optimal.

(4) Rewinding

The slit strip is rewound onto a separate recoiler. Appropriate tension is applied to form an even, tightly wound coil. A good rewinding process prevents damage to the material during transportation or storage.

(5) Inspection and Packaging

Each slit coil is rigorously inspected for dimensional accuracy and edge quality. Qualified products are then securely packaged to prevent damage during transportation. This step is critical to ensure that the product received by the customer meets quality standards.

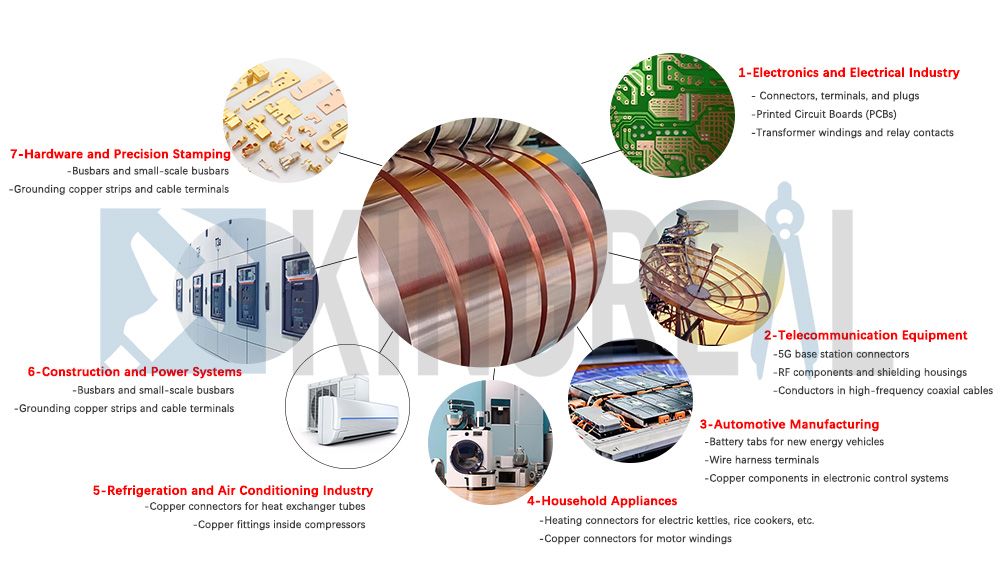

4. Industries and Applications that Depend on Brass Coil Slitting Line

Copper coil slitting machines have a wide range of applications in multiple industries. Here are three major industries and their specific applications:

(1) Electronics industry

In the electronics industry, brass is often used to manufacture connectors, circuit board brackets, and other electronic components. Brass' excellent conductivity and corrosion resistance make it an indispensable material in electronic products. Copper coil slitting machines meet the strict requirements of electronic components for size and quality by providing high-precision narrow strips.

(2) Automotive industry

A large number of brass parts, such as radiators, valves and connectors, are required in automobile manufacturing. These parts require good mechanical properties and corrosion resistance. The efficient cutting ability of brass coil slitting lines can quickly produce high-quality parts that meet automotive industry standards, ensuring the safety and performance of automobiles.

(3) Construction industry

In the construction industry, brass is used for door locks, hinges and other hardware accessories. The beauty and durability of brass make it an ideal choice for high-end architectural decoration. Brass coil slitting machines can accurately cut materials of the required shape and size according to design requirements, meeting the dual needs of functionality and beauty in the construction industry.

Brass coil slitting lines are indispensable equipment in modern manufacturing, and they support multiple industries with their efficient and precise cutting capabilities. By understanding the structure, working principle and importance of brass coil slitting machines, companies can better utilize this equipment, improve production efficiency and reduce costs. Regular maintenance and standardized operation are the key to ensure the long-term and stable operation of the brass coil slitting line. Through reasonable management, enterprises can not only improve product quality, but also gain an advantage in the fierce market competition. I hope this article can provide you with a comprehensive understanding and help you achieve greater success in the field of brass processing.