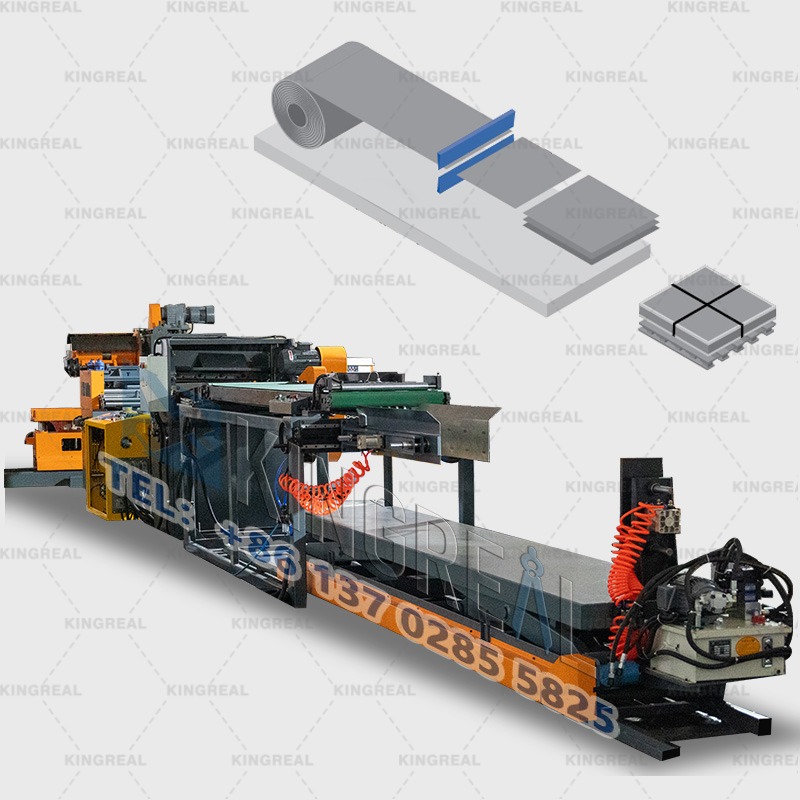

Light gauge cut to length line and medium gauge cut to length line are highly sought-after coil processing equipment in the modern metalworking industry, effectively handling the coil thicknesses required by most industries. In metalworking, high-quality light gauge cut to length line and medium gauge cut to length line not only improve the efficiency of metal processors and manufacturers but also ensure processing precision. This article will delve into the solutions for these two types of cut to length lines, exploring how leading metal processors utilize this technology and why choosing KINGREAL SLITTING metal cut to length lines can meet the production needs of specific sheet metal specifications.

『What is the Function of Metal Cut to Length Line?』

The primary function of a metal cut to length line is to unwind, flatten, and cut large coils of metal into the required lengths for subsequent processing or direct use. Such metal cut to length lines are crucial for manufacturers requiring precision cutting of metal parts, especially in industries such as automotive, construction, and home appliances. The efficiency and precision of the metal cut to length line directly impact the quality of the final product and overall production costs. Therefore, choosing the right metal metal cut to length line is of paramount importance.

『Light Gauge Cut to Length Line』

(1)Specifications of light gauge cut to length line

Light gauge cut to length lines are primarily designed for processing thin metal materials, typically ranging in thickness from 0.008 inches (approximately 0.2 mm) to 0.118 inches (approximately 3 mm). These materials include steel, stainless steel, galvanized steel, and aluminum. The design of the light gauge cut to length line meets the processing needs of multiple industries for thin steel sheets. The length and width tolerances of the metal sheets produced by this light gauge cut to length line are within ±0.005 inches (approximately 0.127 mm), ensuring high-quality processing standards.

(2)Application of light gauge cut to length line

Light gauge cut to length lines are widely used in various industries. The automotive industry relies on light gauge cut to length lines to manufacture body panels and other related components; the construction industry uses them to produce roofing and wall panel materials; and the home appliance industry requires light gauge cut to length lines to manufacture key components for home appliances such as refrigerators and ovens.

(3)Light gauge cut to length line solutions

●Solution 1: KINGREAL SLITTING light gauge cut to length lines provide high-quality billet processing for the construction, mining, and RV industries. This light gauge cut to length line excels in processing sensitive materials, ensuring seamless processing. Simultaneously, the fully automated system from the decoiler to the stacker significantly reduces labor costs and improves work efficiency.

●Solution 2: For suppliers in the steel and HVAC equipment industries, the KINGREAL SLITTING light gauge cut to length line offers a real-time monitoring system that improves production accuracy and efficiency. Production speed can be flexibly adjusted according to specific project needs, preventing material slippage, and the light gauge cut to length line is also equipped with multiple safety features.

●Solution 3: In the roofing and signage industry, the introduction of a light gauge cut to length line can significantly improve productivity and profitability. Regardless of material width or thickness, the light gauge cut to length line achieves precise length cuts and effectively helps companies achieve higher precision in metal flattening and stacking.

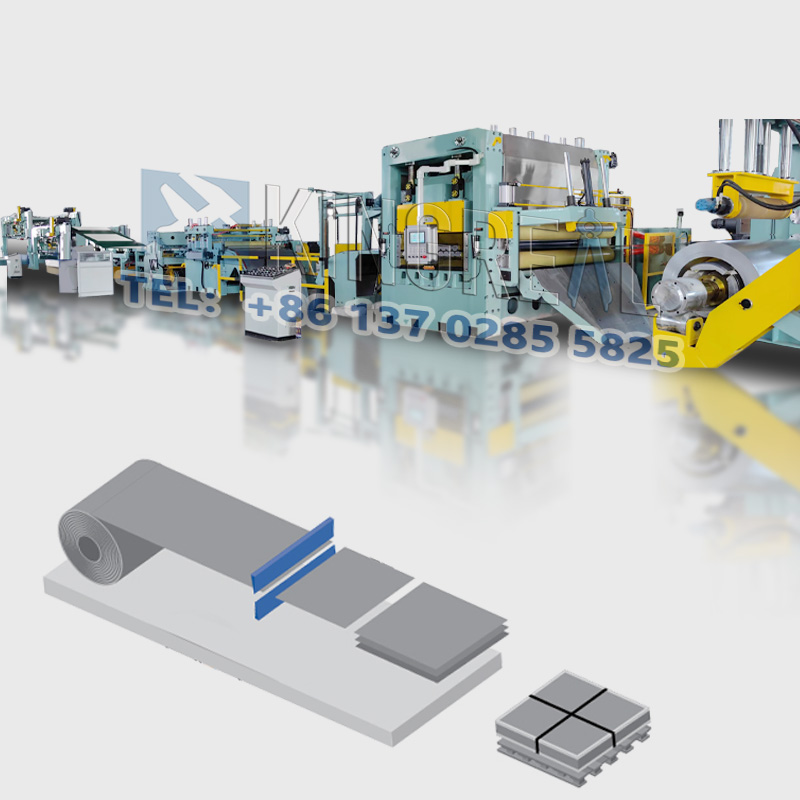

『Medium Gauge Cut to Length Line』

(1) Specifications of medium gauge cut to length line

The medium gauge cut to length line is designed to handle a wider range of industry needs, and its design is suitable for materials with thicknesses ranging from 0.118 inches (approximately 3 mm) to 0.236 inches (approximately 6 mm). This machine can process hot-rolled steel, pickled steel, oiled steel, galvanized steel, pre-coated steel, high-strength steel, and various metal materials (including aluminum, copper, brass, and alloys). Compared to light gauge cut to length lines, medium gauge cut to length lines can handle thicker materials, making them suitable for applications requiring robust and durable metal blanks.

(2) Application of medium gauge cut to length line

Medium gauge cut to length lines are widely used in industries requiring thicker, heavier metal components. For example, the automotive industry uses this equipment to manufacture structural components and chassis parts, the construction industry relies on it to produce beams, columns, and other structural components.

(3)Medium gauge cut to length line solutions:

●Solution 1: Medium gauge cut to length lines offer significant advantages to metal processing companies, helping them gain a competitive edge in the market with high-quality sheet metal. KINGREAL SLITTING medium gauge cut to length lines offer high precision and rapid production capabilities, with innovative safety features and stacker crane designs reducing manual labor and improving overall safety and production efficiency.

●Solution 2: Stainless steel suppliers can also benefit from gauge cut to length lines. KINGREAL SLITTING gauge cut to length lines offer superior length and width tolerances. Its servo-hydraulic clamping and servo-roller feeding system enable deep circulation when processing thick materials, significantly increasing production line speed.

『Why Choose KINGREAL SLITTING Light & Medium Gauge Cut to Length Line?』

Choosing KINGREAL SLITTING light gauge cut to length line and medium gauge cut to length line offers several key advantages:

-Personalized Customization: KINGREAL SLITTING has a professional technical team capable of designing, manufacturing, and assembling metal cut to length lines to meet the unique needs of its clients, providing customized solutions.

-Advanced Technology: KINGREAL SLITTING metal cut to length lines incorporate advanced technologies in their design to achieve unprecedented efficiency, precision, and productivity. These technologies ensure the stability and reliability of the equipment under high-intensity operation.

-Outstanding Performance: KINGREAL SLITTING has accumulated over 20 years of experience in the design and manufacture of metal cut to length line, possessing extensive technical knowledge and expertise to provide customers with high-quality equipment tailored to their specific needs.

-24/7 Service: KINGREAL SLITTING not only strives for excellence in metal cut to length line manufacturing but also prioritizes after-sales service. A professional team is always on standby to provide technical support for equipment operation and maintenance, ensuring users can operate the equipment efficiently and conveniently.

Are you ready to stand out from the competition and achieve greater efficiency and profitability? Contact KINGREAL SLITTING today for a quote.

Are you ready to stand out from the competition and achieve greater efficiency and profitability? Contact KINGREAL SLITTING today for a quote.