After KINGREAL SLITTING's coil slitting machine was sent to the Saudi Arabian customer's factory, it won high praise from the customer after several months of use. The customer gave feedback: "DURABLE AND EFFICIENT, BOOSTS BUSINESS".

It fully affirmed the excellent performance of KINGREAL SLITTING's coil slitting equipment in durability, efficiency and customer business improvement. Thank you for the recognition of Saudi Arabian customers, which is not only a high recognition of KINGREAL SLITTING's product quality, but also a great encouragement for our continued efforts.

Professional manufacturing of coil slitting machines, serving global customers

As a professional coil slitting equipment manufacturer with more than 20 years of experience, KINGREAL SLITTING has been committed to the research and development of high-quality and intelligent slitting equipment. KINGREAL SLITTING provides a variety of types of coil slitting machines, including:

- Belt tension coil slitting machine

- Dual-slitter head coil slitting machine

- Heavy duty coil slitting machine

These coil slitting equipment are not only popular, but also have been successfully exported to many countries and regions such as Russia, UAE, India, Bangladesh. KINGREAL SLITTING is customer-oriented and provides customized coil slitting machine solutions to ensure that the equipment can perfectly match the customer's production requirements. KINGREAL SLITTING’s team of engineers has a deep understanding of the parameter requirements of coil slitting machines in various markets, which makes our equipment more competitive.

Advantages of KINGREAL SLITTING coil slitting equipment

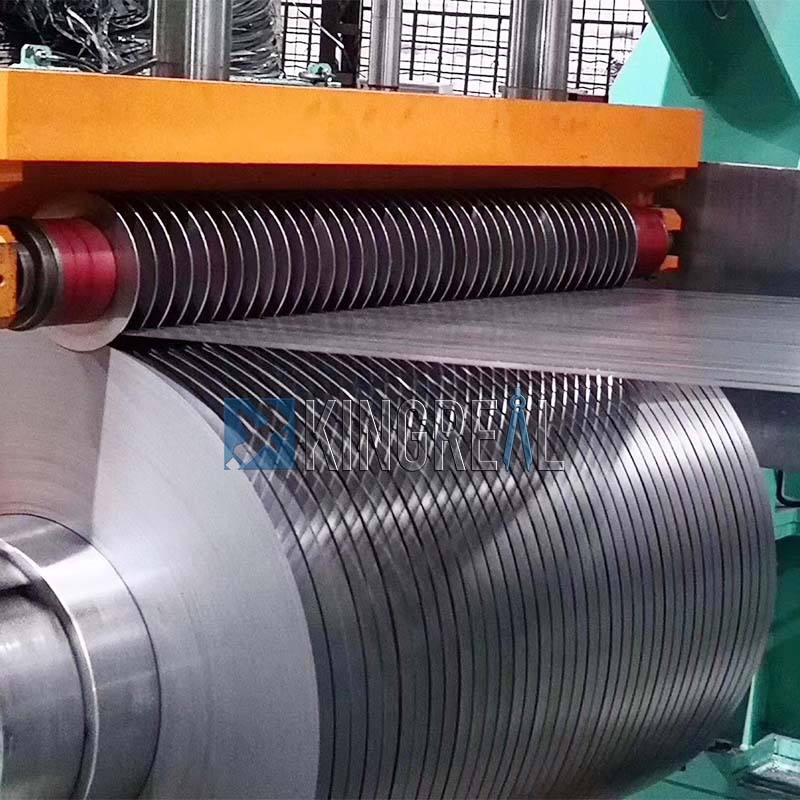

KINGREAL SLITTING coil slitting machines are characterized by high precision, flexibility and efficiency, which can help customers stand out in the fierce market competition. The following are the main advantages of KINGREAL SLITTING coil slitting equipment:

1. Meet the slitting needs of various metal materials

KINGREAL SLITTING has specially designed corresponding equipment for different metal raw materials, including:

- Silicon coil slitting machine

- Aluminum Steel coil slitting machine

- Copper coil slitting machine

These coil slitting equipment cover the needs of metal materials widely used in the market and can meet customers' production application scenarios in multiple industries.

2. Fully automated production line

KINGREAL SLITTING coil slitting machines use fully automated components to form a production line. From unwinding, slitting to rewinding, the equipment runs automatically throughout the process. Customers only need to set parameters on the control panel, and the coil slitting machine can complete the work efficiently, greatly reducing manual participation and reducing labor costs.

3. Fast production speed

In order to help customers improve production efficiency, KINGREAL SLITTING has developed a coil slitting machine that can run at a high speed of 230m/min. This high-efficiency production performance is especially suitable for customers with high production speed requirements.

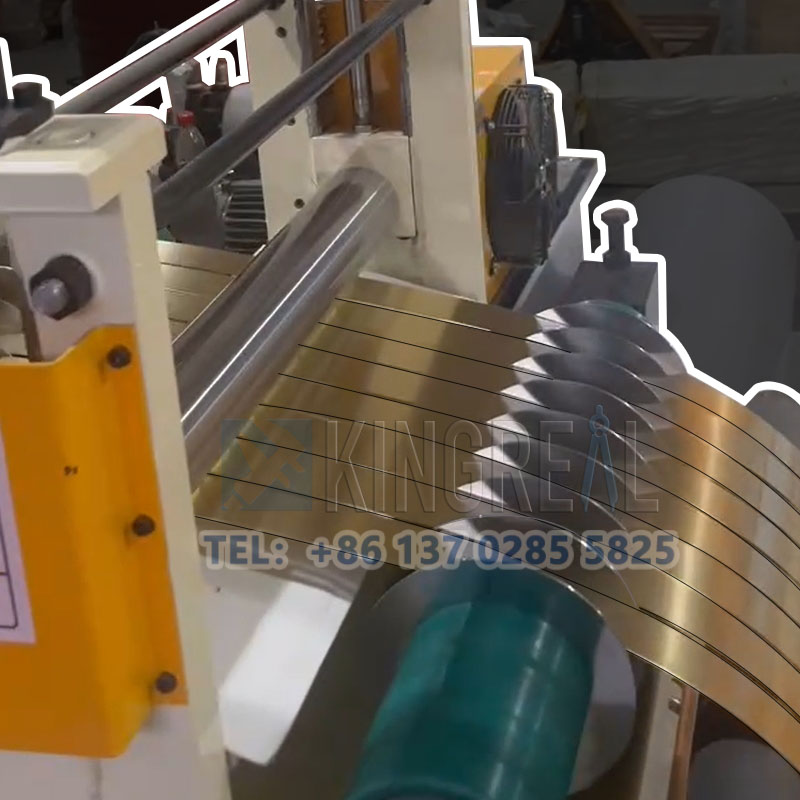

4. Automatic tool changing technology

KINGREAL SLITTING coil slitting equipment are equipped with an automatic tool changing system. Through the automatic tool changing capstan, the tool changing process can be completed in less than 5 minutes. This function effectively reduces the tool changing time and greatly improves the continuity and overall efficiency of the production line.