In modern manufacturing, the demand for medium gauge cut to length machines as an efficient metal processing equipment is growing. Shearing lines play an indispensable role in the automotive, aerospace, construction, electronics and other fields.

With the advancement of automation technology, the use of medium gauge cut to length equipment not only improves production efficiency, but also greatly reduces labor costs. Therefore, it is particularly important to understand how to choose a suitable medium gauge cut to length line. This article will explore in detail the key factors and steps for selecting medium gauge cut to length equipment to help companies make wise decisions.

1. Market demand for medium gauge cut to length machines

Medium gauge cut to length lines are used in various countries and fields. With the transformation and upgrading of the global manufacturing industry, the demand for this medium gauge cut to length equipment continues to rise. Especially in the context of increasing automation, companies are increasingly inclined to invest in efficient and flexible medium gauge cut to length machines to meet production needs. Medium gauge cut to length lines can not only improve productivity, but also reduce the waste of raw materials and improve product consistency and quality. In this case, choosing a suitable medium gauge cut to length machine becomes crucial.

2. Considerations for selecting medium gauge cut to length lines

● Clarify the shearing method

When choosing a medium gauge cut to length equipment, you first need to clarify the required shearing method. Different shearing methods are suitable for different production needs, mainly including:

(1) Flying shear medium gauge cut to length machine

The flying shear medium gauge cut to length line uses high-speed scissors for shearing, which is suitable for production scenarios that require fast shearing. Its advantage is that it can achieve high-speed and high-precision shearing, and the shearing process does not stop, which is suitable for mass production.

(2) Fixed shear medium gauge cut to length equipment

The characteristics of the fixed shear medium gauge cut to length machine are that the coil is stationary during shearing, and the production speed is relatively slow. It is suitable for customers with small production scale or no high production requirements.

(3) Rotary shear medium gauge cut to length line

The rotary shear medium gauge cut to length equipment uses a rotating tool for shearing, which is suitable for processing large-sized coils. Its flexibility enables it to perform well in a variety of processing environments.

When choosing a shearing method, enterprises should choose the most suitable shearing method based on their own production needs and product characteristics.

● Clarify the thickness of the coil to be processed

The thickness of the coil is one of the important factors affecting the selection of medium gauge cut to length machines. According to different thicknesses, medium gauge cut to length lines can be divided into the following categories:

(1) Light gauge cut to length line

Light gauge cut to length lines are usually used to process metal sheets with a thickness between 0.3 - 3mm, suitable for light metal processing applications such as home appliances, electronic products, etc.

(2) Medium gauge cut to length machine

Medium gauge cut to length machines are suitable for processing metal sheets with a thickness between 0.3 - 6mm, and are widely used in machinery, automobile and other industries.

(3) Heavy gauge cut to length equipment

Heavy gauge cut to length equipment specialize in processing heavy metal sheets with a thickness of 6-20mm, suitable for heavy industrial fields such as shipbuilding and construction.

When choosing a metal cut to length machine, enterprises must determine the type of equipment according to the thickness of the coil to be processed to ensure production efficiency and product quality.

● Clarify the metal raw materials

Different metal raw materials have different requirements for medium gauge cut to length lines. Common metal materials include:

(1) Stainless steel medium gauge cut to length equipment

Stainless steel has good corrosion resistance, but its hardness is high. When shearing, you need to choose a specially designed medium gauge cut to length machine to ensure the shearing quality and durability of the tool.

(2) Copper medium gauge cut to length machine

Copper is soft and relatively easy to shear, but in the case of high production, you still need to choose a medium gauge cut to length equipment with high efficiency.

(3) Hot-rolled medium gauge cut to length machine

Hot-rolled medium gauge cut to length line is mainly used to process metal coils produced by hot rolling process. Hot-rolled materials are usually more ductile and are processed by heating the metal to above the recrystallization temperature. When selecting a medium gauge cut to length equipment, the characteristics of the material should be considered to select the appropriate shearing method and tool.

(4) Cold-rolled medium gauge cut to length line

Cold-rolled medium gauge cut to length equipment is mainly used to process metal coils produced by cold rolling process. Cold-rolled materials are more brittle and are processed at room temperature.

● Customized needs

In today's market, customized medium gauge cut to length equipment are increasingly favored by enterprises. Enterprises can communicate with professional engineers according to their actual needs and formulate personalized medium gauge cut to length equipment solutions. Here are some customized options:

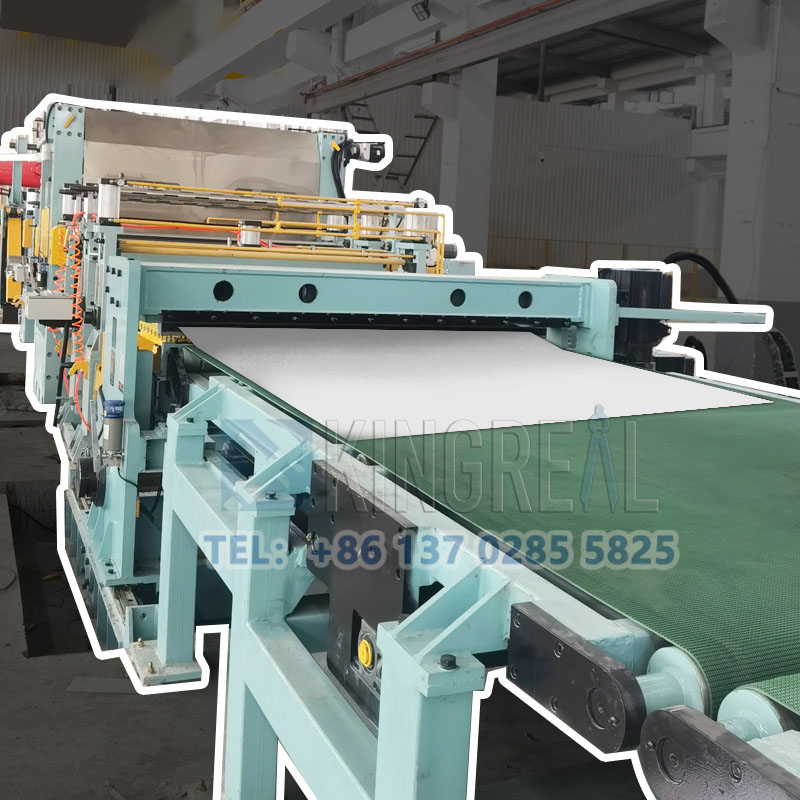

(1) Medium gauge cut to length machine with lamination

Before the metal sheet is fed into the medium gauge cut to length equipment, in order to effectively protect the metal surface and prevent scratches and corrosion, a layer of film is applied to the surface of the metal sheet through the laminating device before it is fed into the medium gauge cut to length machine.

(2) Medium gauge cut to length line with double leveller

KINGREAL SLITTING can provide two levelers for the medium gauge cut to length equipment. The medium gauge cut to length line with double levelers is suitable for products that require high flatness. It can level the metal coil twice before shearing, greatly improving the shearing quality.

(3) Medium gauge cut to length line with double stacker

In order to maximize customer production efficiency, KINGREAL SLITTING is equipped with two stacking tables for customers. The fully automated stacking table stacks the medium gauge cut to length machine that is sheared out, reducing manual operation time.