| Last week, KINGREAL SLITTING warmly welcomed customers from Algeria. Their purpose of coming this time was to visit the KINGREAL SLITTING factory and gain a deeper understanding of the technology of the silicon coil slitting line. They hoped to have a deeper understanding of KINGREAL SLITTING CRGO slitting machine through this meeting. |  |

Arrival and Warm Reception

The KINGREAL SLITTING team picked them up from the customer's hotel and went to the factory. On the way, the two sides communicated very easily and talked about some topics in life, such as sleep conditions, adaptation to Chinese food, and flight experience.

Then, KINGREAL SLITTING staff briefly introduced the factory to the Algerian customers and discussed different workshops, including raw material workshops, sheet metal processing workshops, welding workshops, assembly workshops, and quality inspection workshops. At the same time, they also emphasized the professionalism of KINGREAL SLITTING employees. When asking the Algerian customers which workshop they were interested in, the Algerian customers expressed their desire to visit each workshop in order to fully understand the production process of the silicon coil slitting line.

Safety First: Entering the Factory

After arriving at the KINGREAL SLITTING factory, both parties strictly followed the safety protocol and wore helmets, because KINGREAL SLITTING has strict requirements for production safety and must wear helmets when entering the factory.

Manufacturing Workshop Visit

First, KINGREAL SLITTING staff took the Algerian customer to visit the manufacturing workshop to let the customer witness the production process of the CRGO slitting machine with their own eyes. KINGREAL SLITTING staff detailed that KINGREAL SLITTING has a professional inspection team responsible for strictly monitoring the manufacturing process to ensure that each silicon coil slitting line meets strict quality standards. Through regular inspections and evaluations, KINGREAL SLITTING is able to effectively control the production schedule and machine quality.

The Algerian customer was impressed by this rigorous production process. They learned that each CRGO slitting machine can be customized according to the customer's specific needs, allowing for flexible adjustments in design and functions. This customized approach emphasizes KINGREAL SLITTING commitment to providing customers with solutions to improve production efficiency.

Assembly Workshop Visit

Next, the Algerian customer was taken to the assembly workshop to visit the various components of the silicon coil slitting line that had not yet been assembled. KINGREAL SLITTING staff explained in detail the functions and parameters of each component, and pointed out that these parameters are not fixed, but can be adjusted according to the customer's actual needs and technical drawings.

This flexibility is a significant advantage for Algerian customers who want to improve production efficiency. For example, KINGREAL SLITTING can integrate more automation components for the customer's CRGO slitting machine to meet the customer's optimization needs. The Algerian customer expressed great interest and considered how to apply these customized options to their production line.

Visit to Quality Inspection Workshop

Finally, the Algerian customers came to the quality inspection workshop. Here, they visited several silicon coil slitting lines in operation, including Heavy Duty Slitting Machine,Light Gauge Slitting Machine,Mini Metal Coil Slitting Machine,Dual Slitter Head Slitting Machine,Belt Tension Coil Slitting Machine,etc.

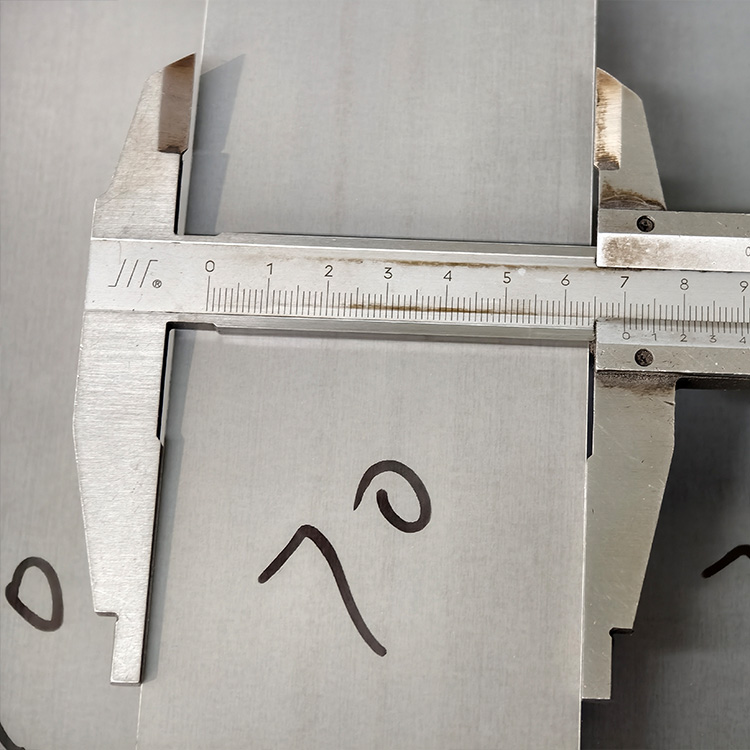

KINGREAL SLITTING staff asked the customer about the expected slitting size and demonstrated how to enter the parameters on the control panel for production. The Algerian customer was invited to test the produced narrow strips. The results were satisfactory, with an error within ±0.1mm, a smooth surface and consistent quality. The Algerian customer showed a high degree of satisfaction.

Establishing a Cooperative Future

During the visit, the Algerian customer not only learned the technical details of the CRGO slitting machine, but also established a good relationship with the KINGREAL SLITTING team. At the end of the visit, the Algerian customer expressed his intention to cooperate with KINGREAL SLITTING initially and shared their specific production needs.

The Algerian customer submitted a list of requirements and hoped that KINGREAL SLITTING engineers could quickly develop a customized silicon coil slitting line manufacturing solution suitable for them. This move marked the beginning of a cooperative relationship between the two parties, and both parties were eager to align their respective goals and capabilities.

About KINGREAL SLITTING

| KINGREAL SLITTING is a CRGO slitting machine manufacturer with more than 20 years of rich experience. So far, various types of KINGREAL SLITTING silicon coil slitting lines have been sold to the Netherlands, Russia, Indonesia, India, Canada, the United States and other countries, and have reached cooperation with many well-known brands. In addition to providing high-quality CRGO slitting machines, KINGREAL SLITTING also provides customers with detailed after-sales service. After the silicon coil slitting line arrives at the customer's factory, KINGREAL SLITTING will send professional engineers to the customer's factory to install the CRGO slitting machine and teach the workers how to use the machine correctly. And they will also inform the customer of the possible situations and solutions during the use of the machine in advance to escort the customer's production. If the machine fails, don't worry. KINGREAL SLITTING will find out the problem and solve the problem of the silicon coil slitting line failure for the customer in the shortest time through online video conferencing or offline field inspections. The CRGO slitting machine failure will not affect the customer's production progress. |  |