Video About Simple Coil Slitting Line

Description of Simple Coil Slitting Machine

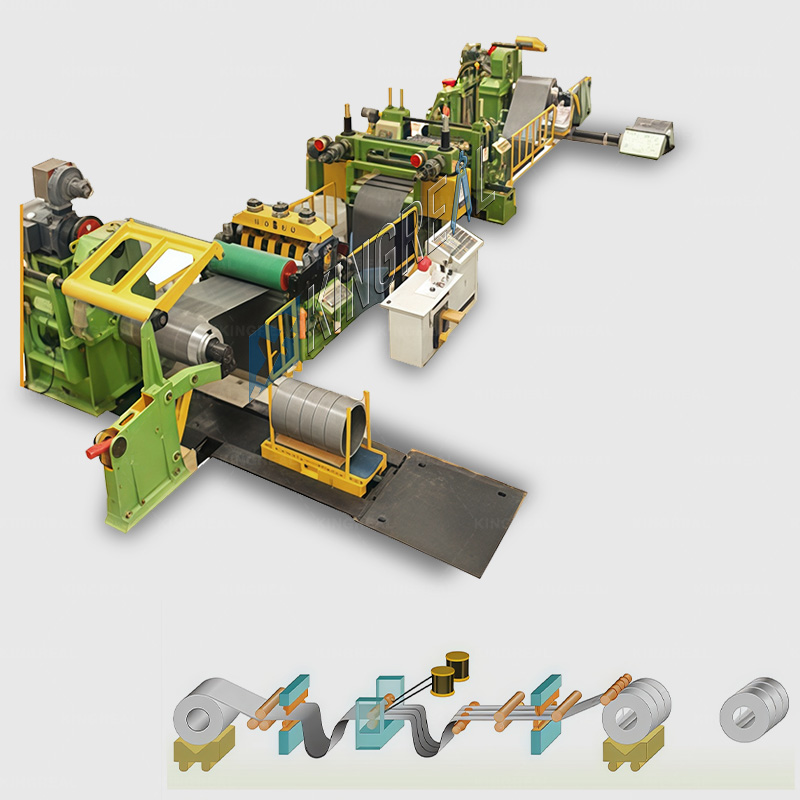

KINGREAL SLITTING simple coil slitting machine is designed specifically to meet the slitting needs of a variety of metal materials. It can process various types of metal coils, including cold-rolled, hot-rolled, carbon steel, silicon steel, tinplate, stainless steel, etc, efficiently slitting them into strips of desired specifications. This simple coil slitting line differs significantly in the width, thickness, strength, and weight of the coils it can process. Designed by KINGREAL SLITTING for customers with lower budgets and less demanding precision requirements, it streamlines the operation process while ensuring production reliability. This simple coil slitting machine is easy to operate and maintain, making it suitable for customers producing small batches. |  |

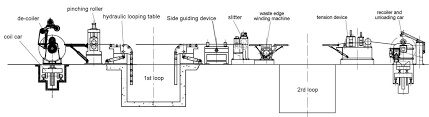

Working Process of Simple Coil Slitting Machine

Loading coils → decoiling → pinching and shearing → looping → guiding → slitting → rewinding scraps → looping → tensioning → recoiling → unloading baby coils → packing

Parameters of Simple Coil Slitting Line

| Coil Material | Hot Strip Steel |

| Raw Material Weight | 4t |

| Raw Material Outer Diameter | 1200mm |

| Raw Material Inner Diameter | 508mm |

| Raw Material Width | 350mm |

| Raw Material Thickness | 0.8-2.0mm |

| Slitting Width | 30mm |

| Slitting Capacity | 5-10 Strips |

| Slitting Accuracy | 0.03mm |

| Single-Side Slitter | 0.1mm |

| Finished Coil Outer Diameter | 1200mm |

| Finished Coil Inner Diameter | 508mm |

| Production Speed | 0-80m/min |

| Total Machine Capacity | 50kW |

Key Components of Simple Coil Slitting Line

(1)Decoiler for simple coil slitting machine

The decoiler is responsible for unwinding the metal coils. Its design features an expandable mandrel that clamps according to the coil's inner diameter, ensuring coil stability during processing. The coil rotates off the mandrel and smoothly feeds into the simple coil slitting line's edge guides, preparing it for further processing.

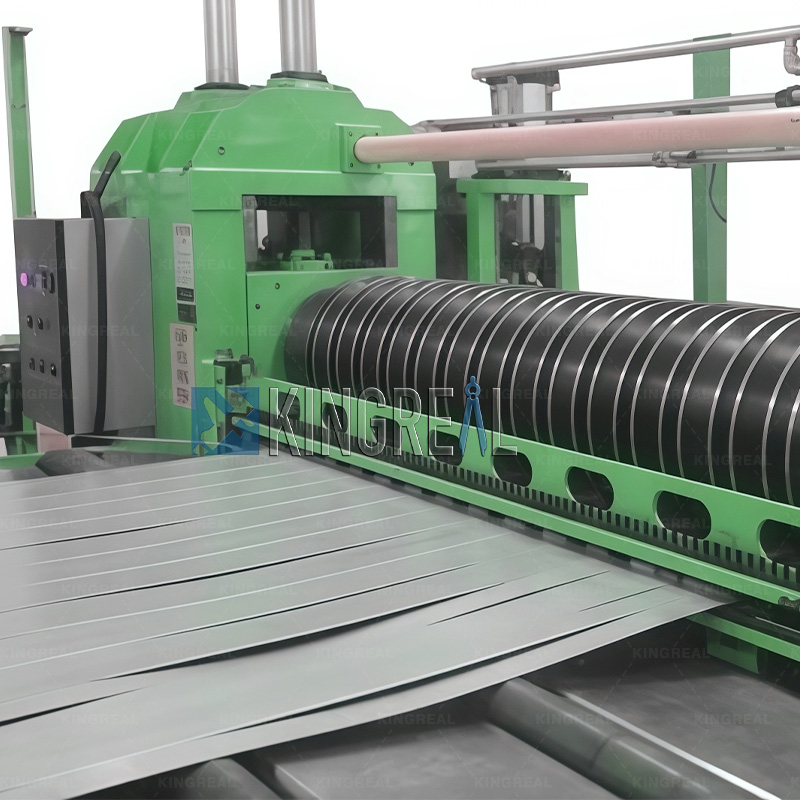

(2)Main slitter for simple coil slitting line

The simple coil slitting machine is responsible for cutting metal material lengthwise into strips of the desired width. The slitting head consists of two parallel mandrels, equipped with custom-designed rotating slitting knives and a rubber stripper ring. The knives precisely penetrate the steel, breaking or cracking the material, ensuring the quality of each slit strip. KINGREAL SLITTING uses precision tooling and cutting tools to ensure optimal slit edges, while a computerized automation system precisely controls the spacing and knife clearance.

(3)Waste collection device for simple coil slitting line

During the slitting process, coil scrap requires proper handling. The waste collection device, constructed from a welded steel plate frame, features a self-contained design. Its primary function is to recover scrap generated after slitting, reducing environmental pollution during production and facilitating recycling. The hydraulically controlled unloading system is easy to operate and ensures efficient waste disposal.

(4)Recoiler for simple coil slitting line

The recoiler's primary function is to rewind the slit coils into a shape suitable for packaging and shipping. Its design ensures tight and neat rewinding, paving the way for subsequent logistics and transportation.

Features of Simple Coil Slitting Machine

PLC system for simple coil slitting line: The simple coil slitting machine utilizes an advanced PLC numerical control system, enabling efficient and precise automated control. An encoder measures cut lengths, and on the touchscreen users can input data including cut speed, quantity, and length. The simple coil slitting line stops automatically once the set cut amount is achieved, hence boosting manufacturing efficiency considerably. The speed of the simple coil slitting machine can be changed as needed to satisfy various production needs.

High measurement accuracy for simple coil slitting line:A sophisticated control system ensures a precision of 0.03mm for each cut, meeting high-standard production requirements.

Fully automated operation for simple coil slitting line: The simple coil slitting machine's fully automated design significantly reduces manual intervention and operational errors, ensuring stable production.

Small footprint for simple coil slitting line: Compared to standard metal slitting machines, simple coil slitting machines have a lower installed capacity and occupy less floor space, making them particularly suitable for small-batch production operations.

Material compatibility for simple coil slitting line: Simple coil slitting machines can process a variety of metal materials, offering a wide range of adaptability to meet the needs of diverse customers.

Economical and practical: For customers with a tight budget, simple coil slitting machines offer a cost-effective option while maintaining performance while minimizing equipment costs.

Benefits of Using a Simple Coil Slitting Machine

(1)Product Consistency

To guarantee that the dimensions and thickness of every strip stay inside the required parameters, the simple coil slitting machine employs sophisticated slitting technology and a precise control system. Particularly in sectors needing great accuracy like car manufacturing and electronics assembly, this consistency is critical for future processing.

Moreover, the exactness of the simple coil slitting machine simplifies product storage and transit. Uniform strips are simpler to pack and stack, therefore lowering damage risk during transportation. By utilizing simple coil slitting lines, businesses may cut travel expenses dramatically and increase transportation efficiency. supervision and upkeep let them concentrate more on essential manufacturing operations.

(2)Reducing Waste and Improving Product Quality

Simple coil slitting machine let buyers choose the ideal slitting width for the finished product, thereby drastically lowering material waste. Conventional slitting techniques generate a lot of scrap or waste, which not only lowers manufacturing efficiency but also raises operating expenses. Simple coil slitting lines, on the other hand, enable businesses to accurately cut as per real needs, therefore reducing the material destined as trash. Reducing waste helps businesses not only lower material costs but also raise general product quality.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil