What Is Steel Coil Slitting Line?

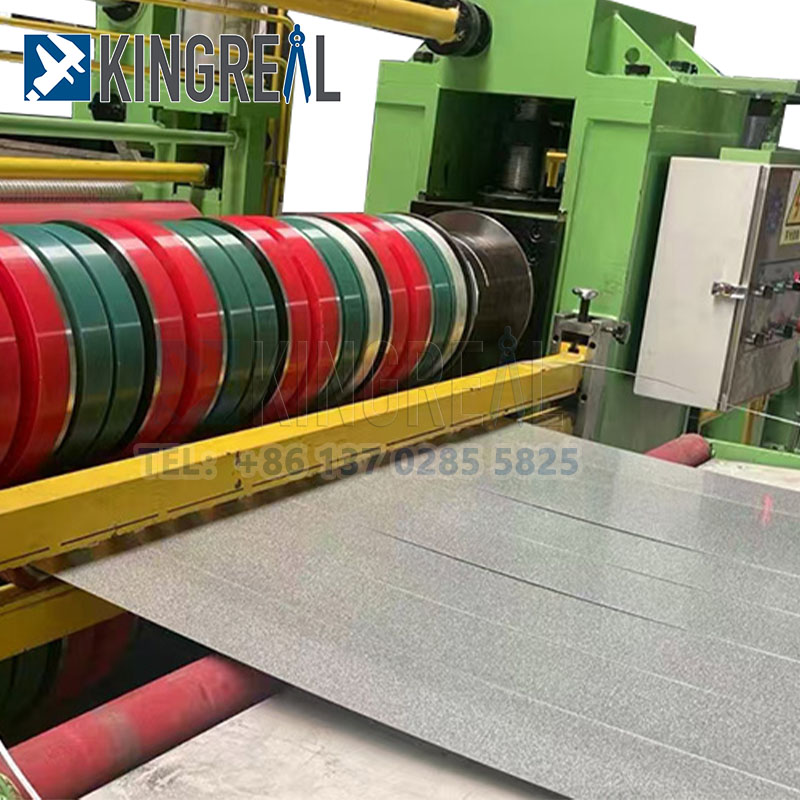

As the core equipment in the field of modern metal processing, Steel Coil Slitting Line cuts metal coils into strips of predetermined width with millimeter-level precision. The steel slitting machine is a production line system consisting of an unwinder, a leveling device, a precision disc shear, a scrap edge winder and a finished product coiler. Through hydraulic servo and CNC technology, it realizes the automatic strip processing of metal sheets and produces metal strips of customer-specified width. Steel Coil Slitting Line is widely used in many industries such as transformers, motors, home appliances, automobiles, building materials and packaging. It is suitable for shearing tinplate, silicon steel sheets, aluminum strips, copper, stainless steel plates and galvanized plates.

The blade shaft structure of Steel coil slitting line is forged with chromium-molybdenum alloy steel. After vacuum heat treatment, the hardness can reach HRC62-63, which is sharp and durable. The high-precision photoelectric correction system of Steel slitting line monitors the deviation of the strip in real time and strictly controls the shearing tolerance within the range of ±0.1mm.

Steel coil slitting machine is an intelligent equipment integrating mechanical, electrical and hydraulic functions. It not only meets the stringent demands of the automotive, home appliance, construction and other industries for precision metal strips, but its modular design also enables flexible production of the production line, making the metal coil processing process harmonious and smooth.

What Is High Speed Steel Slitting Line?

"High Speed Steel Slitting Line is designed for rapid processing of metal coils of different raw materials with a thickness of 0.3-3MM. The slitting speed of the coils can reach up to 200M/Min. With its high slitting speed and precise metal coil surface processing technology, it has become one of the must-have processing equipment for many metal processing factories."

How was the High Speed Steel Slitting Line designed?

1/Fully automatic coil unwinding system for metal slitting machine

The metal slitting machine is equipped with a fully automatic coil unwinding system. The hydraulic unwinding machine consists of a frame, a main shaft, an expansion and contraction reel, an unwinding and pressing device, a brake device, a clutch device, and a power part. At the same time, the metal slitting machine is equipped with an automatic loading trolley and an auxiliary support arm to adapt to the production speed of rapid unwinding of metal coils.

2/Upgrade of the slitting knife seat of the metal slitting machine

The slitting knife seat of High Speed Steel Slitting Line consists of a frame, a knife shaft, a knife shaft arch, a synchronous lifting device, and a power system. The slitting blade is 2CrMo alloy steel, with a specification of Ф240mm×2000mm, with a key-way, and has undergone 8 processes including rough processing, tempering treatment, medium frequency treatment, grinding, hard chrome plating, and re-grinding; to ensure that the knife shaft does not deform under temperature changes, fatigue, and load changes, thereby ensuring the longitudinal shearing accuracy.

High Speed Steel Slitting Line is equipped with air cooling + minimal lubrication (MQL) as standard, which can control the cutting area temperature to ≤80℃ in real time to avoid thermal deformation.

3/Steel Coil Slitting Line bridge design synchronizes production speed

The main structure of the High Speed Steel Slitting Line bridge consists of two sets of front and rear parts: profiles, steel plates, steel rods, curved feed plates, etc. There is also a curved feed plate and steel plates connected, and the roller moves with the bridge. The Steel Coil Slitting Line bridge is designed to smoothly transition the material into the longitudinal shearing main machine when it is raised, and to make the material fall into the buffer zone to match the production speed when it is lowered.

4/High Speed Steel Slitting Line separator

The High Speed Steel Slitting Line separator consists of a frame, a main shaft, a retractable reel with a jaw, a winding separator, a brake device, a deceleration device, an auxiliary support, a pusher, and a power part. The Steel Slitting Line separator supports the steel strip and provides sufficient winding force. After the material separation is completed, the pusher helps the unloading trolley to move the steel strip from the rewinder;

5/High Speed Steel Slitting Line transmission system upgrade

High Speed Steel Slitting Line uses digital servo motors, with a response speed of milliseconds and a torque control accuracy improvement of more than 30%. 200M/Min High Speed Steel Slitting Line is equipped with preloaded ball screws and low-friction linear guides to reduce vibrations in high-speed reciprocating motion and support stable operation at 180-200M/Min

(0.3-3)×1600MM High Speed Steel Slitting Line Specification

Steel Coil Parameters | Material | HR CR PO |

Thickness | 0.3-4.0mm | |

Material width | 800-2000mm | |

Coil outer diameter | ≤Φ2000mm | |

Coil inner diameter | Input:Φ460~Φ520 Φ560~Φ620 Output: Hydraulic recoilΦ508 | |

Max weight of coil | 15T | |

Steel Slitting Line Parameters | Inner diameter | Φ508mm |

Outer diameter | ≤Φ1800mm | |

Product Max capacity | Max:20T | |

Slitted strips | 0.3-3.0mm thickness max 30 strips 3.0-4.0mm thickness max 15 strips | |

Min Strip width | 25mm | |

Width Tolerance | ≤±0.1mm | |

Width range of waste edge | 2-10mm | |

Slitting Speed | 0-120m/min |

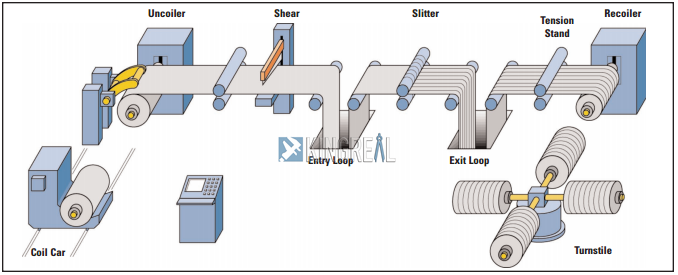

Working Processing Of High Speed Steel Slitting Line

Upload material - Decoiler - Clip feed leveler/shearer - First Loop bridge - Guide and Slitting - Scrap collection - Second Loop bridge - Recoiler - Unload Coils

Feature Of High Speed Steel Coil Slitting Line

The main components of the hydraulic system of High Speed Steel Coil Slitting Line are made of high-precision components, and the electrical control uses imported PLC program controller and touch screen for full-line function control. It has the characteristics of high degree of automation, good leveling quality, high shearing accuracy, stable and reliable performance, and convenient operation and maintenance. The coil material in the Metal Slitting Machine can be loaded once to achieve the smooth completion of each process, effectively reducing the labor intensity of workers. It has a high cost-effectiveness and is a high-performance product integrating machinery, electricity and hydraulics.

◆ The whole machine has a reasonable design structure, compact shape, high precision, high efficiency, and flexible and convenient adjustment

◆ The frame is welded with steel plates, annealed, and formed in one go using a CNC floor-standing boring and milling machine, ensuring high strength and high precision

◆ The manufacturing process of the whole machine is strictly produced in accordance with the design specifications of the machine, and the leveling roller material is alloy steel 60CrMoV

◆ The working shaft support of the whole machine adopts heavy-duty bearings, with advanced lubrication system, and long service life

◆ It has more professional slitting line technology and has a number of slitting line application technology patents, which fully meet user requirements

◆ The whole line is PLC controlled, with touch screen display and operation, and a high degree of automation

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil