▍Description of Heavy Gauge Slitting Line

The KINGREAL SLITTING heavy gauge slitting line is designed specifically for processing metal coils with a thickness of 4-25mm, precisely slitting the coils into multiple narrow strips. After processing, these strips can be easily reeled, facilitating long-distance transportation or subsequent secondary processing.

KINGREAL SLITTING heavy gauge slitting machine is suitable for processing a variety of metal materials, including aluminum, stainless steel, hot-rolled steel, and cold-rolled steel, and is also capable of processing a variety of coated materials. Built with safety and productivity in mind, this heavy gauge slitting line provides consumers with a solution combining both. Minimizing manual effort, increasing consistency and accuracy in the manufacturing process, and lengthening the lifespan of molds all benefit from the fully automated heavy gauge slitting machine.

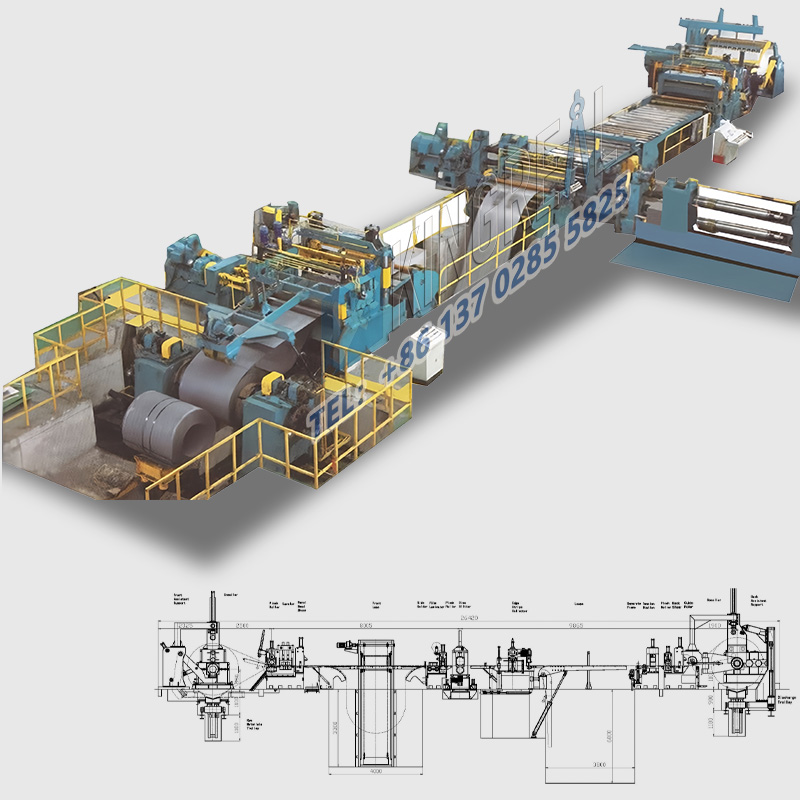

▍Workflow of Heavy Gauge Slitting Machine

Entry coil car → Decoiler → Press and pinch device → Hydraulic cutter → Looper 1 → Side guide device → Slitter → Scrap winder → Looper 2 → Tension stand → Recoiler → Exit coil car

▍Parameter of Heavy Gauge Slitting Machine

Parameter | Specification |

Material Thickness | 4mm – 25mm (customizable for thicker materials) |

Material Types | Carbon Steel, Stainless Steel, Aluminum, HSLA |

Coil Width | 500mm – 2000mm |

Coil Weight | Up to 40 tons (higher capacities available) |

Slitting Speed | 0 – 120 m/min |

Number of Slitting Strips | Up to 30+ (based on material and width) |

Blade Material | High-strength alloy steel or tungsten carbide |

Recoil Outer Diameter | Up to 1600mm |

Tensioning System | Hydraulic or Pneumatic |

Line Configuration | Fully automated with manual override options |

Control System | PLC-based with HMI touchscreen interface |

Power Supply | 380V/50Hz (or as per regional standards) |

Hydraulic Pressure | 15 – 25 MPa |

Uncoiler Capacity | Up to 40 tons |

Recoiler Capacity | Matches uncoiler specifications |

Slitting Blade Adjustment | Automatic or manual with quick-change features |

Scrap Handling | Scrap choppers or edge ballers included |

Flatness Control | Integrated leveling devices for tension control |

Lubrication System | Automatic centralized lubrication |

Safety Features | Emergency stop, overload protection, guarding |

Floor Space Requirement | Approx. 30m (L) x 8m (W) (varies by configuration) |

▍KINGREAL SLITTING Heavy Gauge Slitting Line Solution

KINGREAL SLITTING heavy gauge slitting line utilizes a set of rotating slitting blades to efficiently cut a single coil into multiple narrower coils. Designs for heavy gauge slitting machines from KINGREAL SLITTING consider particular customer needs including weight, width, raw material, plate thickness, coil outer diameter, coil inner diameter, and maximum coil weight. To guarantee top performance in their manufacturing process, every heavy gauge slitting line is customized for the customer's particular requirements.

1) Customized design for heavy gauge slitting machine

KINGREAL SLITTING heavy gauge slitting lines offer flexible designs to meet diverse customer needs. Since customer requirements and specifications may vary, KINGREAL SLITTING offers a range of customization options, including:

Raw Material Selection: Whether it's aluminum, stainless steel, or other metals, KINGREAL SLITTING heavy gauge slitting machines can easily handle them.

Sheet Thickness and Width: They accommodate coils ranging from 4 to 25mm, ensuring they meet customer requirements for various thicknesses and widths.

Coil Outer and Inner Diameter: We precisely design the coils based on the customer's specified outer and inner diameters.

Maximum Weight and Slitting Quantity: KINGREAL SLITTING designs the maximum weight and slitting quantity based on actual production requirements.

Finished Product Width Accuracy and Burr Control: KINGREAL SLITTING ensures that each finished product meets customer standards, minimizing the risk of burrs.

Through these customized designs, KINGREAL SLITTING heavy gauge slitting lines efficiently meet the diverse needs of our customers in slitting production.

2)Blade configuration for heavy gauge slitting line

Because KINGREAL SLITTING heavy gauge slitting machines can process coils up to 25mm thick, blade configuration was a top priority in their design. KINGREAL SLITTING engineers focused on ensuring blade strength while also ensuring cutting accuracy. Utilizing advanced cutting technology and control systems, the heavy gauge slitting lines ensure high cutting precision, minimizing errors during the production process. This blade design not only improves cutting efficiency but also extends blade life and reduces maintenance costs.

3)Efficient production for heavy gauge slitting line

KINGREAL SLITTING heavy gauge slitting machines excel in production efficiency. Their fully automated design significantly reduces labor requirements during the production process, improving production efficiency. While traditional metal slitting machines often require extensive manual intervention, KINGREAL SLITTING heavy gauge slitting lines utilize an intelligent control system to automate the production process. With simple setup, users can complete large-scale slitting operations in a short period of time.

Moreover, to guarantee consistent and stable cutting, the heavy gauge slitting machine monitors cutting condition in real time during operation. Should anything happen, the heavy gauge slitting line will automatically stop to guarantee safe production. This effective manufacturing approach improves consumers' market competitiveness by allowing them to get greater results more quickly.

4) Safety design for heavy gauge slitting machine

KINGREAL SLITTING heavy gauge slitting lines are equipped with multiple safety features to ensure operator safety during operation. Whether during startup, operation, or shutdown, the heavy gauge slitting machine's safety mechanisms effectively prevent accidents.

For instance, the emergency stop button on the heavy gauge slitting line lets the operator immediately halt the equipment should there be an anomaly. Moreover, the housing of the heavy gauge slitting machine includes safety elements to avoid possible wounds during operation.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil