What Is Medium Gauge Coil Slitting Line?

Coil Slitting Machine, also known as steel slitting line, coil slitting line or metal slitter, is a device specially designed for slitting and shearing coils such as tinplate, galvanized iron, silicon steel sheet, cold-rolled strip, stainless steel strip and aluminum strip. Coil slitting machine can accurately cut metal coils into strips of various predetermined widths and roll these strips into small coils for subsequent use. In transformer, motor manufacturing and other industries that require precise shearing of metal strips, steel coil slitting line is an indispensable key equipment.

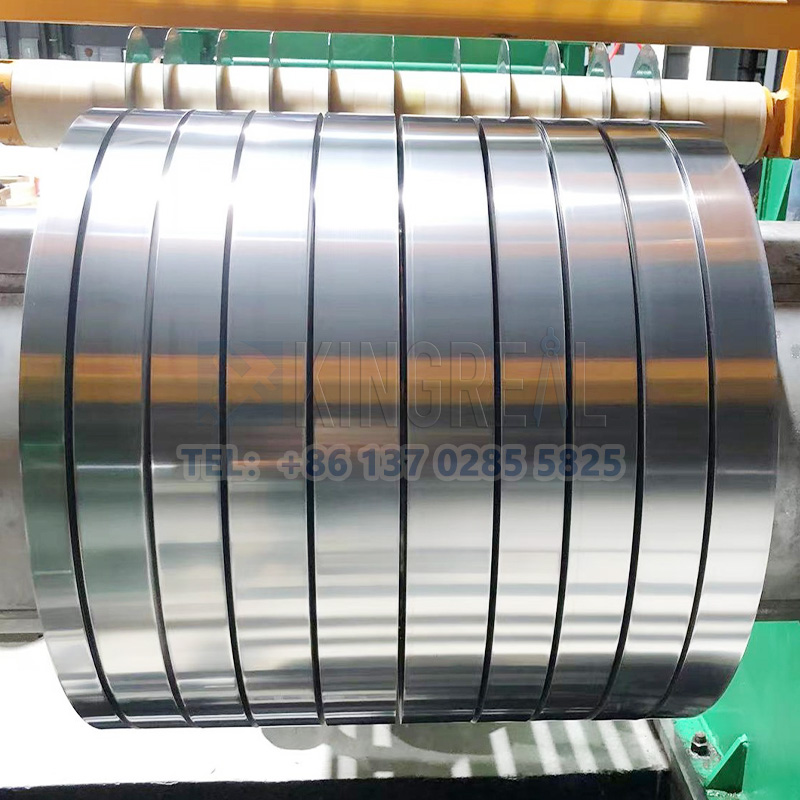

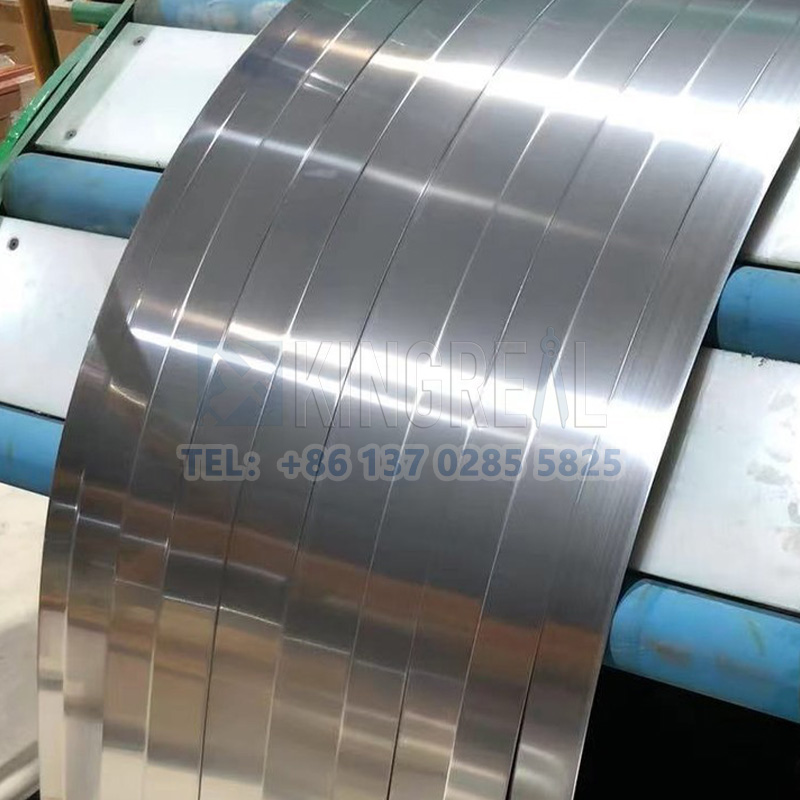

Medium Gauge Coil Slitting Line is specially designed for processing metal coils with a thickness range of 3-6MM. It adopts PLC control system, precise leveling device and sharp slitting blade group to achieve precise shearing ability and stable performance. Medium Gauge Coil Slitting Line can efficiently complete the slitting of strips and rewind the cut narrow strips into coils for subsequent use. Medium Gauge Coil Slitting Line is easy to operate, has excellent cutting quality, high material utilization, and the cutting speed can be adjusted steplessly to meet various production needs. Medium Gauge Coil Slitting Line equipment is specially designed for metal strip shearing. It is easy to operate, has high cutting quality, reasonable structure, and improves production efficiency.

Medium Gauge Coil Slitting Line mainly consists of several core parts such as unwinding, material positioning, strip slitting and coiling. Each link has been carefully designed to ensure the stability and efficiency of the entire production process.

Main Technical Specification For Coil Slitting Line

Steel Coil Parameters | Material | HR CR GI |

Steel Thickness | 0.4-4.0mm | |

Steel Width | 500-1650mm | |

Steel coil I.D | Φ508mm | |

Steel coil O.D | ≤Φ1800mm | |

Steel Coil Weight | 20 Ton | |

Tensile strength | δb≤500Mpa,δS≤260Mpa | |

Slit Strip Coil Parameters | Slit Strip Coil I.D | Φ508mm |

Slit Strip Coil O.D | ≤Φ1800mm | |

Max Slit Quantity | Thickness: 0.3-1.0mm≤25 strips; 3-4.0≤8 strips | |

Width precision | ≤±0.05mm | |

Coil Slitting Machine Parameters | Slitting Speed | 20-120M/Min |

Capacity | 380V/50Hz/3Ph | |

Area | Length 26m×Width 12m |

What Is Main Component Detail Of Steel Coil Slitting Line?

1/ Hydraulic Decoiler With Loading Trolley For Steel Coil Slitting Machine

Form Steel plate welded frame, hydraulic expansion and contraction mandrel

Quantity 1 unit

Load bearing 35T

Inner diameter of steel coil Φ508mm

Outer diameter of steel coil MAX: Φ1800mm

Arc plate structure of unwinding drum Double-head structure

Used to feed the unwinder, transport the steel coil from the storage table to the reel of the unwinder, the trolley is controlled by a hydraulic motor, and the lifting is controlled by a hydraulic cylinder. Carrying steel coils, expanding the inner diameter of the coils, unwinding and unloading or recycling the coils. Supporting the coils and providing tension to the steel strips, it consists of a frame, a main shaft, an expansion and contraction reel, an unwinding and pressing device, an auxiliary support, a brake device, and a power part.

2/ Press and Pinch Device For High Speed Coil Slitting Line

Quantity 1 set

Material GCr15

Number/diameter of pinch rollers 2×Φ180mm

Number and diameter of leveling rollers 5×Φ120mm

Quantity 1 set

Transmission mode Cylinder-driven cutting, powered by hydraulic cylinder

Cutting mode Cutting from top to bottom

Used for cutting irregular head plates. Prepare for the subsequent process. Driven by cylinder, the gap between the scissors blades can be adjusted manually when cutting plates of different thicknesses. The blades of the four-sided scissors can be replaced and used alternately. Cutting from top to bottom.

3/ Looper Design For Metal Coil Slitting Line

Used to control the synchronization and buffering of the steel belt speed between the slitting machine and the feeder. The table is made of nylon board to ensure that the board surface will not be scratched. Three pairs of electric eyes control the position of the steel belt in the loop pit to maintain sufficient storage capacity in the pit.

4/Pressing Device For Steel Coil Slitter

Quantity 1 set

Plate width 500-1650mm

Width adjustment method Left and right adjustment by hand wheel

Vertical roller material GCr15 steel

Clamping roller Φ150mm×1650mm

Used for positioning in the width direction of the plate to prevent the steel plate from running off. Vertical rollers are provided on both sides of the plate width direction, fixed on their respective sliding seats, and the sliding seats are adjusted by the oil cylinder to move along the plate width direction on the guide rail to adapt to different plate widths.

5/Main Steel Coil Slitter Machine

The steel slitting machine is a device that cuts the strip into various widths longitudinally. By replacing the combined spacer, the width of the cut product can be flexibly changed. The knife shaft adjustment adopts the method of fixing the lower shaft and adjusting the upper shaft to the worm gear synchronously to adjust the knife shaft spacing, which can accurately control the gap between the upper and lower shafts. The upper and lower knife shafts are both fastened with nuts as axial fastening, and the upper and lower knife shaft ends are equipped with knife protection sleeves. The side-opening frame (motor driven) is adopted, which is convenient for replacing blades.

6/ Scrap Collection For Metal Slitting Line

The scrap edge collection device of the metal slitting machine equipment is a special equipment used to automatically recover the scrap edges generated by cutting during the slitting process of metal sheets. Its core function is to realize continuous collection of scrap edges, avoid downtime processing, and improve production efficiency and operational safety through automated design. The bottom plate is driven by a motor to achieve 180° rotation of the connecting rod, switch the position of the double collection rollers to avoid downtime; the sliding seat and the screw rod are linked to make the scrap edges evenly distributed during winding and improve the winding quality.

The slitting and collection rack is equipped with a gear rack transmission system, which can move along the slitting bracket to adapt to the scrap edge collection at different cutting positions; the collection pipe is connected to the negative pressure system to directly transport the scrap edges to the collection box to reduce scattered pollution.

7/Pre-Separation Tension Damping Device

Separate the strips after longitudinal cutting to prevent stacking when passing through the tensioner, so as to facilitate collection. There are two sets of separation discs. The separation disc shaft can be removed from the operating side for easy replacement and cleaning. The tension machine dynamically adjusts the coil tension to ensure that the material is flat and wrinkle-free during the slitting process, and that the narrow strips after slitting are evenly wound to avoid interlayer dislocation.

Front separation frame: It adopts a guide rail independent frame. The frame is connected to the main frame through two hard chrome-plated guide rods. The separator is installed on the separator shaft. The separator shaft can be pulled out of the machine body to install separators and sleeves, which is very convenient; the front separation frame is equipped with a cylinder that can move up and down relative to the main frame and can stop at any height.

Tension table: It consists of a side plate archway, an upper gantry, a lower pad, an upper pad, and a cylinder. The wool felt can be fixed on the upper and lower pads. The plate belt passes between the upper and lower pads, pressing the pad to generate tension. The upper pad is synchronously driven by two cylinders.

8/Recoiler Device For Metal Slitting Line

The rewinding device is responsible for winding the slit metal strip neatly into a coil and maintaining a stable tension to ensure the quality of the finished product. Its design directly affects the winding tightness, edge neatness and production efficiency of the slit material. The winding machine consists of a frame, a reel, a transmission system, an expansion and contraction system, a braking system, a lubrication system, a hydraulic system, etc.

The motor drives the main shaft of the coiler to rotate. The expansion and contraction cylinder provides tension to cause the slide on the main shaft to move and slide, and the wedge-shaped slider and the slide are displaced to achieve the expansion and contraction of the reel.

How To Operate The Gauge Gauge Coil Slitting Line?

First, the material is placed on the inlet storage table and then transported to the uncoiler by the inlet trolley. After preliminary processing by the inlet guide roller and the material opening device, the strip enters the straightening machine for straightening. If welding is required, it enters the welding machine (reserved space).

Then, the angle cutter (reserved space) cuts the strip, and the side guide device assists.

After that, the strip enters the slitting machine for slitting, and the resulting scraps are processed by the scrapping machine and sent out through the waste conveying device. The outlet looper and tension table device are responsible for maintaining the stable tension of the strip.

Finally, after further processing by the outlet cross-cutting and guide device, the strip is rolled into small coils by the coiler and output in an orderly manner through the outlet front end roller and cross arm storage device.

In the entire process, the 7 motors of the machine train are all controlled by inverters to ensure stable and reliable operation to meet the various needs of users.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil