〡What is Carbon Steel Slitting Machine?

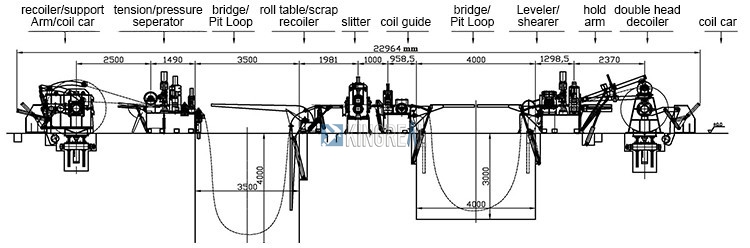

Carbon steel slitting machine is a metallurgical production equipment used to slit wide coiled steel strip into several narrow strips. The carbon steel slitting line consists of a discharge table, loading trolley, uncoiler, pinch and straightening roller assembly, hydraulic shear, front roller conveyor, guide system, slitting machine, rear roller conveyor, edge wire coiler, feed platform, tensioning device, pressure-splitting device, pressure-splitting guide plate, reeler, reeling shaft support arm, unloading trolley, hydraulic station, pneumatic station, and electronic control system.

KINGREAL SLITTING offers customized carbon steel slitting machine manufacturing solutions, providing customers with high-quality, high-precision carbon steel slitting lines that ensure each slit carbon steel coil meets precise specifications, minimizing waste and maximizing production efficiency.

〡What is Working Process of Carbon Steel Slitting Line?

Loading coil car → Uncoiler → Straightener device → Pinch roll & leveler & hydraulic shearer → Loop pit → Side guide → Slitter → Transition platform & scrap winder → Loop pit → Tension station → Recoiler → Unloading coil car

〡Main Parameters of Carbon Steel Slitting Machine

(1) Specification requirements of raw material coil

Material: Q235 hot-rolled carbon steel plate

Thickness: 2-8mm

Width: 600-1800mm

Inner diameter: 508-762mm

Outer diameter: 1000-2000mm

Weight: 30T

(2) Specifications of finished products

Strip width: ≥100mm

Width accuracy: ±0.2mm tolerance

Inner diameter of coil: Ф610mm

(3) Main performance and specifications of the unit:

Number of longitudinal cuts: 12 (≤13 cuts for 4mm plate);

Strip width: minimum 100mm

Strip accuracy: ±0.2mm

Thickness range: 2-8mm

Unit speed: 20-80m/min

Total installed power: 600KW

Production line elevation: 800mm

〡Main Components of Carbon Steel Slitting Line

1. Hydraulic press and pinch device for carbon steel slitting line

The hydraulic press and pinch device are essential components of the carbon steel slitting machine, improving the surface quality and straightening the carbon steel plate. This device consists of a drive unit, two pressure rollers, and a frame. The gap between the pressure rollers is manually adjustable to ensure high-quality straightening. All rollers and the gearbox are driven by a 30-kW motor, providing reliable power.

2. Looper for carbon steel slitting machine

The looper chassis is equipped with two sets of photoelectric sensors to control the speed buffer between the uncoiler and the slitting shear. This device eliminates speed differences and ensures that the carbon steel plate maintains the correct trajectory during cutting. A hydraulic cylinder raises the bridge to allow smooth passage of the steel plate. During operation, the bridge lowers, depositing the carbon steel in a pit. A photoelectric device adjusts the speed to high or low to ensure the correct amount of carbon steel stored in the pit.

3. Side guide device for carbon steel slitting line

This device uses vertical rollers on both sides to guide the carbon steel plate into the slitting shear. The rollers are adjusted by guide rods on both sides, with a width range of 500-1250 mm to prevent the plate from skewing. The rolling mill frames are fixed in position on both sides of the plate width, and the width can be manually adjusted to accommodate plates of varying widths. There are four rollers, two on each side, and they are hardened (HRC 55-58) for improved wear resistance.

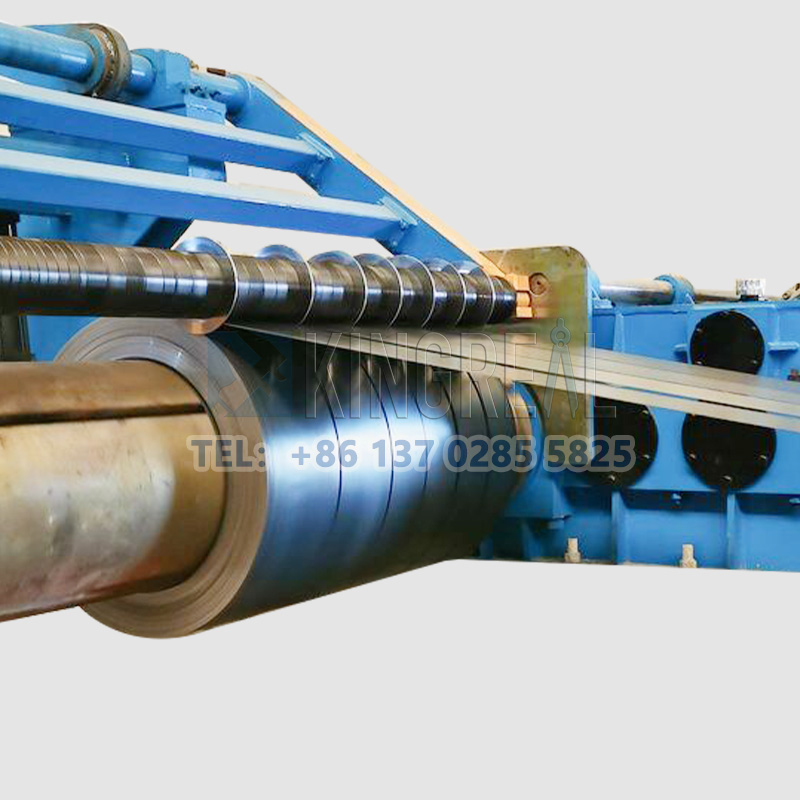

4. Slitter for carbon steel slitting machine

The blade shafts of the carbon steel slitting line are φ200 x 1350 mm, made of 40Cr with a heat-treated hardness of HB 225-250. The main machine consists of a base frame, fixed bracket, large slide, blade shaft, movable bracket, slide, bracket front and rear adjustment mechanism, and blade shaft lift and pressure adjustment mechanism. The blade shaft pressure mechanism is motorized, and blade replacement is quick and easy using a hydraulically operated bracket.

〡Advantages of Carbon Steel Slitting Machine

Customized carbon steel slitting machine manufacturing:

KINGREAL SLITTING provide customized carbon steel slitting machine solutions based on customer-specific coil thickness, width, output, and production speed.

Compatible with various materials for carbon steel slitting line:

It can process a variety of metal materials, including carbon steel, color-coated steel, and galvanized steel, to meet diverse customer needs.

Intelligent control system for carbon steel slitting line:

Equipped with an intelligent control panel, it allows for flexible adjustment of production parameters, enhancing operational flexibility and convenience.

〡Why Use a Carbon Steel Slitting Machine?

Carbon steel coils are available in a wide range of widths, making carbon steel slitting lines particularly important when different widths of raw carbon steel are required for forming different profiles.

Carbon steel slitting machines allow carbon steel coils to be cut into various required widths to meet the specific needs of various industries.

A complete carbon steel slitting line begins with a hydraulic coil car and uncoiler. The steel coil is continuously unwound, passes through straightening and shearing components, and is stored in a hook before reaching the main section of the carbon steel slitting machine, which includes blades and spacers for slitting the coils.

After slitting, the steel strip enters the storage ring again for recoiling. The recoiler rewinds the carbon steel strip under high tension and polarized power, making it an essential component of the carbon steel slitting line.

〡Applications of Carbon Steel Slitting Machines

The narrow carbon steel strips produced by carbon steel slitting machines are important industrial raw materials and are widely used in the automotive, machinery manufacturing, construction, and other fields.

With global climate change and increasing awareness of environmental protection, low-carbon economy and green development have become a global consensus. Therefore, carbon steel slitting machines have emerged. Through technological innovation and industrial upgrading, they aim to increase product added value, meet market demand, and promote green and low-carbon development.

By continuously optimizing production processes and improving equipment performance, KINGREAL SLITTING is committed to providing customers with efficient and precise carbon steel slitting machine manufacturing solutions to promote the sustainable development of the steel industry.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil