Video About Belt Tension Coil Slitting Machine

Slitter Machine And Metal Slitting Machine

The basic principle of operation of a slitter is that a large roll of material is unwound by an decoiler, the material is cut into strips of the desired width as it passes through the slitting tool set, and then rewound into a new roll by a winder. Throughout the process, a tension control system ensures that the material is maintained at the proper tension to ensure cutting accuracy and strip quality.

The main function of a metal coil slitter is to slit large metal coils (e.g., steel coils, stainless steel coils, aluminum coils, etc.) into narrow strips of the desired width. This process requires high precision and efficiency to ensure the quality and consistency of the final product.

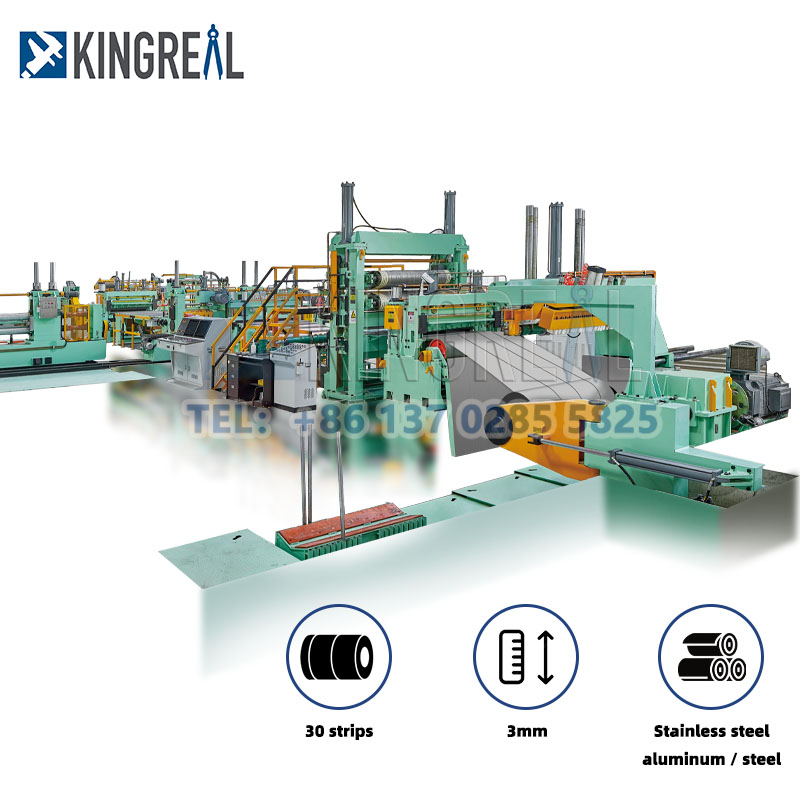

Belt Tension Coil Slitting Machine

The high precision slitting process is one of the greatest features of belt tension coils slitting line. The Belt Tension Slitting Line Machine is designed to process materials with a thickness of up to 3mm and a maximum coil width of 1600mm, operating at speeds of up to 180m/min and capable of producing 30 cutting strips simultaneously. This advanced machine is the ideal choice for coil processing center users, providing both efficiency and precision.

The entire slitting line is controlled by a PLC system with a computer display, utilizing state-of-the-art computer control systems from reputable brands such as Mitsubishi, Yaskawa, Siemens, Baumueller, Delta, and Schneider. These systems allow for easy input of order amounts, cutting strip specifications, and operational speeds directly into the PLC, ensuring smooth and precise operation.

The Belt Tension Coil Slitter, known for its high precision and performance, employs belt bridles, which are particularly beneficial for customers requiring precision surface treatments. This setup ensures minimal surface damage and high-quality finished products, making it a preferred choice for demanding applications.

Advantages of the Belt Tension Slitting Line

Efficiency: Capable of processing coils up to 3mm in thickness and 1600mm in width at high speeds, making it ideal for high-volume production environments.

Precision: The integration of advanced PLC control systems ensures that each cut is precise and consistent, a key characteristic of a high precision coil slitting machine.

Versatility: Suitable for a wide range of materials and applications, from automotive to construction, thanks to its robust design and adaptability.

High Quality Output: Designed to meet stringent surface quality requirements, ensuring that the final product is free from indentations, scuffing, and other imperfections. This makes it an exemplary high quality steel slitting machine.

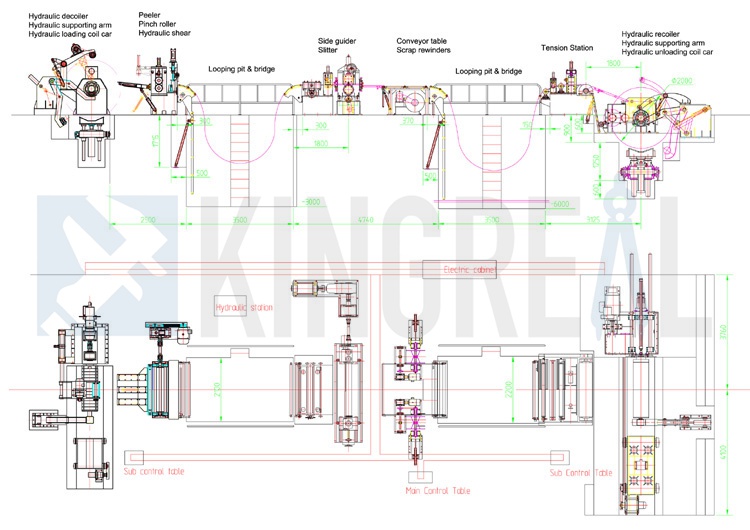

Main Component List

1.Coil car

2.Decoiler

3.Peeler entry table

4.Straightener.

5.Shearing machine

6.Loop table

7.Coil guide and pinch roll

8.Slitting machine

9.Scrap winder (both sides)

10.Loop table

11.Separator and tension table

12.Deflector roll and exit threading table

13.Rewinding

14.Over arm separator in the rewinding.

15.Exit coil car for rewinding

16.Hydraulic system

17.Pneumatic system

18.Electrical control system

Technical Specification Of Steel Slitting Machine

Raw Material | Galvanized steel, stainless steel or SS |

Coil Thickness | 0.2-0.8mm |

Coil Width | Up to 1600mm |

Motor Power | 4.5kw |

Max Cutters Pieces | According to client‘s coil width exact width |

Efficiency | 3 to 4 tons /day |

Power Source | 3xAC380V, 50HZ |

Main Machine Dimension | 2600*1200*1200 mm |

Weight | 800KG |

Application | Slitting Galvanized steel, stainless steel |

Working Process Of Belt Tension Coil Slitting Machine

Trolley loading coil -- Hydraulic vertical centering of decoiler -- Hydraulic decoiler -- Pinch and lever -- Plate head shears -- Loop bridge -- Slitting machine -- Tension station -- Separating -- Rewinding machine

Feature Of High Precision Coil Slitting Machine

1. Enhanced Details on Belt Tension Slitting Line Machine

The Belt Tension Slitting Line Machine, an exemplary high precision coil slitting machine, ensures that the recoiled coils are meticulously aligned with minimal staggered layers, resulting in a compact and tidy final product. This precision is critical for maintaining the integrity and usability of the recoiled strips in various applications.

2. Neat and Tidy Recoiling

The recoiling process produces neat and tidy coils with small, tight staggered layers. This ensures efficient storage and handling, as well as maintaining the quality of the recoiled strips.

3. Scratch-Free Surface

During the recoiling phase, the belts and strips remain relatively undisturbed, preventing any surface scratches. This is particularly important for customers with high surface quality requirements, as it ensures the strips remain pristine, making the machine a top-tier high quality steel slitting machine.

4. Versatile Design

The machine features a combined design of belt bridle and woolen felt pressing type, which can be raised or lowered for interchange within the same frame. This versatility allows for adjustments to meet different processing needs, enhancing the machine's applicability across various metal slitting tasks.

5. Adjustable Tension Control

Depending on the type and thickness of the input material, the tension can be easily adjusted by modifying the cylinder pressure. This feature allows operators to fine-tune the machine for optimal performance, ensuring precise slitting results and making it an indispensable high precision coil slitting machine.

FAQ:

Why does a metal slitter need to be equipped with a belt tension station?

The belt tension station ensures that the metal strips maintain consistent tension throughout the slitting process. This is essential for achieving precise and uniform cuts, as fluctuating tension can lead to warped, broken, or uneven strips. During the recoiling phase, the belt tension station keeps the metal strips stable and taut, reducing the risk of surface scratches, indentations, and other damage. This is particularly important for applications requiring a high quality steel slitting machine, as it ensures the finished strips are in pristine condition.

Consistent tension helps improve cutting precision, making sure each strip is of uniform width. This level of accuracy is vital for a high precision coil slitting machine, where precise cuts are imperative for the final product's quality and usability. A belt tension station allows the machine to operate at high speeds without the risk of slack or slippage in the metal strips, thus enhancing overall production efficiency. This is especially important for large-scale operations and applications that rely on a high quality steel slitting machine.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil