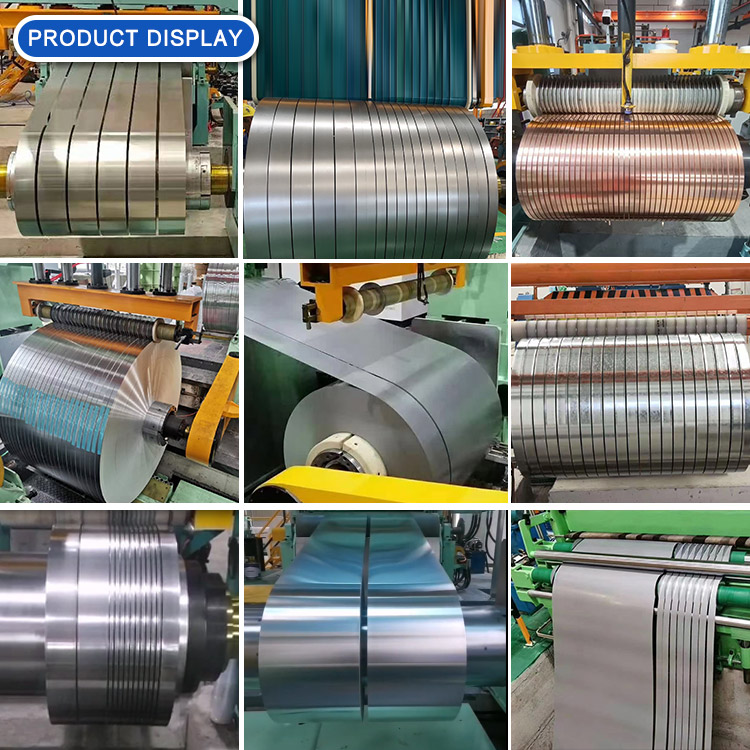

1.Definition of silicone steel slitting machine

Silicone steel slitting machine is a kind of equipment specially used to cut metal coils into narrow strips of the size required by customers. This equipment plays an extremely important role in modern manufacturing, especially in the processing industry of metal materials such as silicon steel, aluminum, copper, etc. By accurately cutting large coils into strips of small width. Silicone steel slitting line not only improves production efficiency, but also can flexibly adjust the cutting size according to the specific needs of customers to meet diverse market needs.

2. Advantages of silicone steel slitting lines

The wide application ofsilicone steel slitting machines is inseparable from their own many advantages, which make silicone steel slitter an indispensable and important equipment in the metal processing industry.

2.1 High degree of automation

Modern silicone steel slitting machines are usually equipped with advanced automation control systems, which can achieve fully automated operation. This feature not only reduces manual intervention and the probability of human error, but also improves production efficiency. The automation system can monitor the equipment status in real time, adjust the cutting parameters in time, and ensure the stability of cutting quality.

2.2 Improve production efficiency

The design of the silicone steel slitting line enables it to complete a large number of metal strip cutting work in a short time. Compared with the traditional manual cutting method, the silicone steel slitter has a faster cutting speed and significantly improved production efficiency. This enables enterprises to meet market demand within a shorter delivery period, thereby enhancing their competitiveness.

2.3 Split multiple narrow strips at the same time

Modern silicone steel slitting machines are usually equipped with multiple blades, which can cut a roll of metal material into multiple narrow strips at the same time. This ability not only improves processing efficiency, but also effectively reduces production costs and increases the profit margin of enterprises.

2.4 Fast speed

The cutting speed of the silicone steel slitter can usually reach tens of meters per minute, which is much higher than the speed of traditional manual cutting. This advantage enables enterprises to complete a large amount of cutting work in a short time and respond quickly to market changes.

2.5 Significant cost-effectiveness

The silicone steel slitting line can effectively reduce production costs by improving production efficiency and reducing material waste. Although the initial investment is high, in the long run, the use of the silicone steel slitter can bring significant economic benefits to the enterprise and enhance overall competitiveness.

2.6 Flexible adaptation to market demand

The silicone steel slitting line can flexibly adjust the cutting width and length according to the specific needs of customers, allowing enterprises to quickly respond to market changes and meet the personalized needs of different customers. This flexibility gives enterprises greater living space in the highly competitive market.

2.7 Improve product quality

The high-precision cutting of the silicone steel slitter can effectively reduce material waste and improve the qualified rate of finished products. At the same time, the automated control system can ensure the stability of the cutting process and further improve the overall quality of the product.

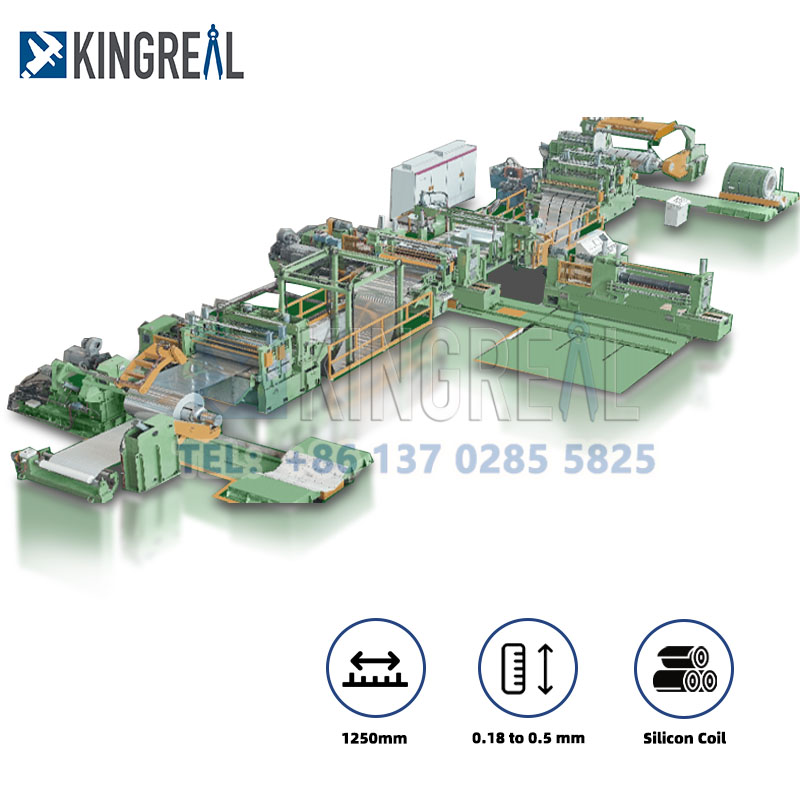

3. Main components of silicone steel slitting lines

The design of silicone steel slitter usually includes multiple precision components, which work together to ensure the efficient operation of the equipment and high-quality cutting results. The following are the main components of the silicone steel slitter:

3.1 Decoiler

The silicone steel slitting line is responsible for unwinding the metal coil from the reel and flattening it so that it is ready for the subsequent cutting process. Modern silicone steel slitting machines are usually equipped with automatic control systems that can automatically adjust the unwinding speed according to the diameter and weight of the coil.

3.2 Tension Station

The function of the tension station is to control the tension of the coil during the cutting process to ensure the stability of the cutting process. By properly adjusting the tension, the coil can be prevented from wrinkling or deforming during the cutting process, thereby improving the cutting quality.

3.3 Front Loop

The front loop is an important part connecting the silicone steel slitter and the cutting machine, which is used to adjust and stabilize the feeding speed of the coil. It can effectively buffer the workload of the cutting machine and ensure the continuity of the cutting.

3.4 Main Coil Slitter

The main slitting knife is the core component of the silicone steel slitting line and is responsible for the actual cutting work. Modern silicone steel slitter are usually equipped with multiple blades, which can cut the coil into multiple narrow strips at one time, greatly improving processing efficiency.

3.5 Waste Collection Device

The waste collection device is used to collect metal waste generated during the cutting process to ensure a clean production environment. This device can reduce the workload of workers to clean up and improve work efficiency.

3.6 Back Loop

The function of the back loop is to guide the cut metal strip to the reel. It is usually equipped with a guide device to ensure the smooth operation of the metal strip during the reeling process.

3.7 Recoiler

The reel rewinds the slit metal strip for subsequent storage and transportation. Modern reelers usually have automatic control functions and can automatically adjust the reeling speed according to the thickness and width of the coil.

4. Market demand for silicone steel slitter

With the development of the global economy, the market demand for silicone steel slitting line is growing. Especially in countries with rapid industrialization, such as China, the United States, Germany, Japan and India, the application fields of silicone steel slitting machine are very wide. The following are some of the main application areas:

4.1 Power industry

In the power industry, silicon steel is a key material for manufacturing transformers and motors. Silicone steel slitter helps manufacturers improve production efficiency and reduce material waste by slitting silicon steel coils into the width required for power equipment.

4.2 Automobile manufacturing

The automobile manufacturing industry has a huge demand for metal materials, especially in parts such as body structure and electric motors. The application of silicone steel slitting lines in this field can effectively cut metal coils into precise specifications required by cars and commercial vehicles, improving the overall performance and safety of the car.

4.3 Home appliance industry

The home appliance industry also relies on silicone steel slitter to process metal materials. Whether it is a refrigerator, washing machine or air conditioner, high-quality metal parts are required, and silicone steel slitting machines can provide the required various types of metal strips to ensure product quality and production efficiency.

4.4 Aerospace

In the field of aerospace, the requirements for materials are extremely strict. Silicone steel slitter can provide high-precision and high-strength metal strips to meet the manufacturing needs of aircraft and spacecraft.

4.5 Electronics industry

The manufacture of electronic products requires precision metal parts. Silicone steel slitting lines can quickly and accurately cut out the required metal strips to meet the high requirements of electronic equipment for materials.