Video About Steel Coil Packing Line

In modern manufacturing, the application of automation technology has become an important means to improve production efficiency and reduce costs. In the metal processing industry, especially in the slitting process of steel coils, the traditional manual packaging method is not only inefficient, but also has many safety hazards. Before the automated steel coil packing line, after the heavy gauge slitting machine processed the metal coils into narrow strips, a large number of workers were needed to sort, pack and stack them. This method not only slowed down the production process, but also increased labor costs and safety risks.

For example, although the slitting speed of theheavy gauge slitting machine can be very fast, the subsequent manual packaging speed often cannot keep up, resulting in a bottleneck in the production line. In addition, the narrow strips have sharp cuts, and workers are prone to injury during operation, increasing the risk of industrial accidents. In response to these challenges, manufacturers have designed fully automated steel coil packing machines that can be used with heavy gauge slitting machines. This innovation has greatly improved the overall efficiency of slitting processing and promoted the development of the entire industry.

Importance of steel coil packaging machines

1. Speed up factory processes

The introduction of fully automated steel coil packing machines has significantly accelerated the factory's production process. Factories using steel coil packaging machines can process more narrow strips in the same amount of time, which not only improves production efficiency, but also enables manufacturers to meet market demand more quickly. For example, a factory using an automated steel coil packing line can process 100 narrow strips in an hour, while a traditional manual baling factory may only be able to process 50, significantly increasing production. For customers who need timely delivery, this efficiency improvement is undoubtedly a huge advantage.

2. Effective use of human resources

With fully automated steel coil packing machines, workers can focus on more creative and strategic work instead of repetitive and inefficient physical labor. Machines can handle those monotonous and dangerous tasks, allowing human resources to be more reasonably allocated. For example, workers can turn to jobs that require more human judgment and creativity, such as quality control and machine maintenance, thereby improving the job satisfaction and productivity of the entire team.

3. Save labor costs

In many developed countries, such as the United States, Germany, and Japan, labor costs are very high. Taking the United States as an example, the average hourly wage in 2023 is about $30. For traditional baling work that requires a lot of manpower, labor cost expenditures will increase significantly. Investing in a fully automated steel coil packaging machine can pay for the equipment at one time, and then reduce the reliance on manual labor. Many factories can recover the investment cost after using the steel coil packing machine several times, and the return on investment (ROI) is considerable.

4. Guarantee quality and quantity

The perfect combination of fully automated steel coil packaging machine and heavy gauge slitting machine forms a fully automated production line, which ensures the stable output of products in terms of quality and quantity. The machine will not feel tired after working for a long time, nor will the work quality be reduced due to subjective factors. This consistency and reliability make the manufacturer's products more competitive in the market, and customers' trust in product quality will also increase accordingly.

Fully automated slitting solution

The fully automated slitting solution closely combines the heavy gauge slitting machine with the steel coil packing machine, enabling manufacturers to achieve better resource integration and project implementation capabilities. This integration not only improves production efficiency, but also makes manufacturers more competitive in the market. By optimizing the production process, manufacturers can respond to market changes more quickly and improve customer satisfaction.

For example, a large steel manufacturing company successfully shortened the production cycle and saved about 20% of production costs by introducing a fully automated steel coil packing machine. This kind of success story is not uncommon in the industry. More and more manufacturers are beginning to realize the importance of fully automated steel coil packaging machines and gradually realize the transformation of production methods.

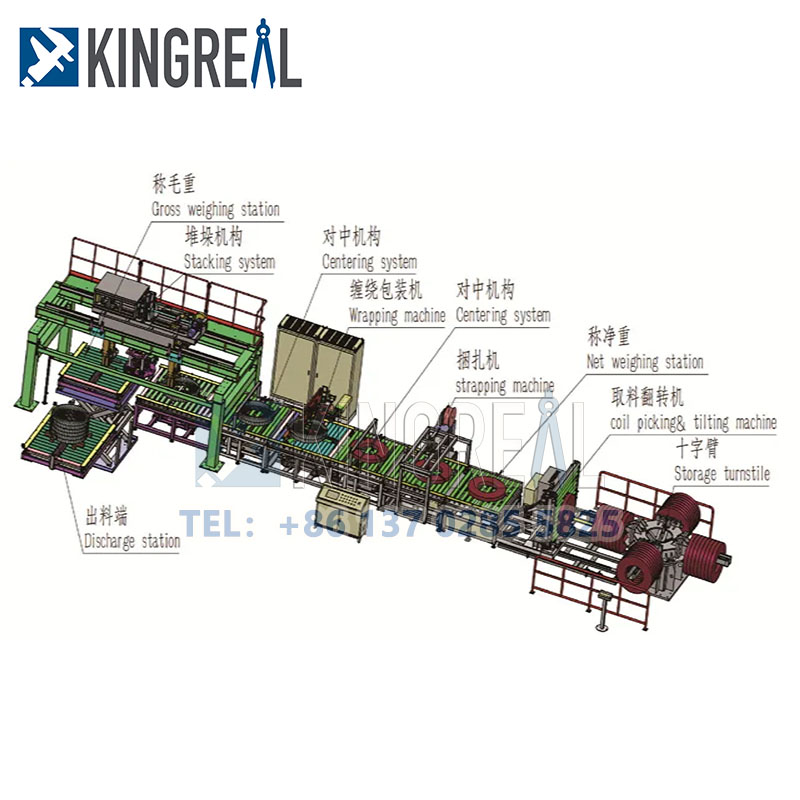

Workflow of steel coil packaging machine

The workflow of a fully automated steel coil packing machine usually includes the following steps:

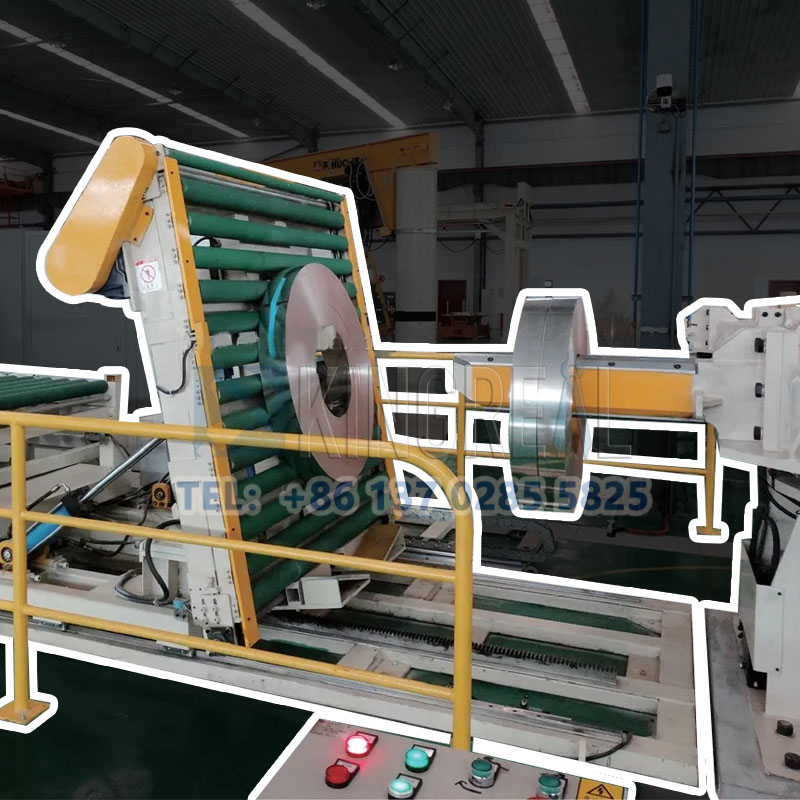

1. Tilting

In the initial stage of the steel coil packaging machine, the narrow strips after stripping are adjusted by a tilting device to ensure that they can smoothly enter the subsequent baling process. This step is designed to reduce the need for manual operation and reduce the risk of errors.

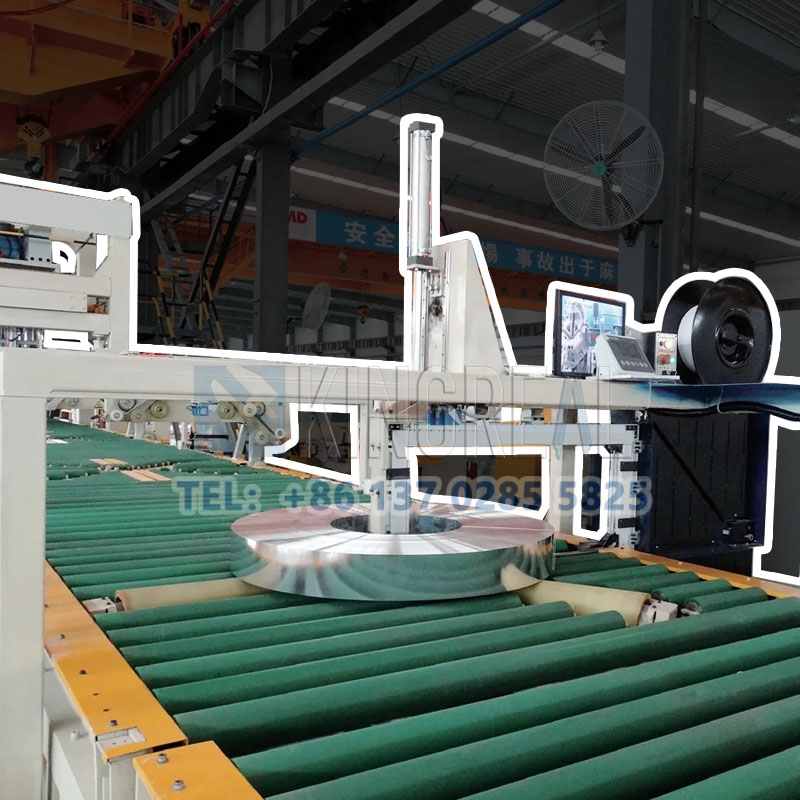

2. Wrapping

Next, the narrow strips are wrapped by a wrapping device. The device usually wraps with plastic film or cardboard to ensure that the narrow strips are not damaged during transportation and storage. The wrapping process is automated and can adjust the tightness of the wrapping according to different product specifications to ensure that each narrow strip is properly protected.

3. Automatic labeling

After wrapping is completed, the steel coil packing machine automatically labels. Each narrow strip will be affixed with a label with a barcode or QR code to facilitate subsequent logistics tracking and inventory management. Automatic labeling not only improves efficiency, but also ensures the accuracy of information and reduces the errors that may occur in manual labeling.

4. Secondary Wrapping

To further enhance the stability of the strips, the steel coil packaging machine usually performs secondary wrapping. This process usually uses stronger materials to ensure that the strips will not move or be damaged during transportation. This link is an important step to ensure that the product arrives intact when it reaches the customer.

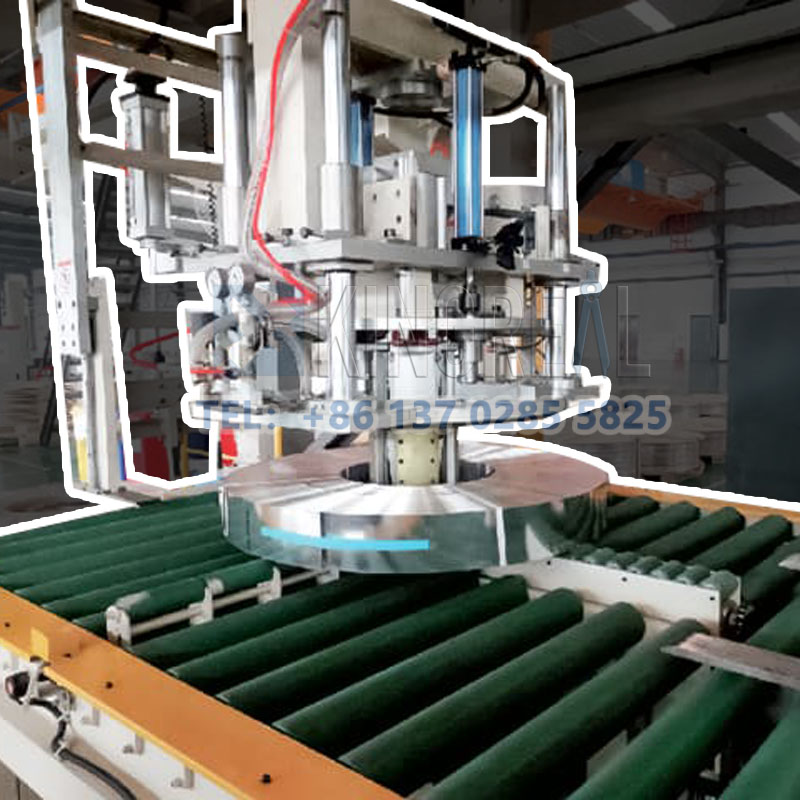

5. Coil Centering

After wrapping, the steel coil packing machine automatically centers the coil. This step ensures that each packaged strip can remain stable during stacking to avoid tilting or collapse due to unevenness. This design not only improves the safety of stacking, but also provides protection for subsequent transportation.

6. Stacking

Finally, after all the steps, the packaged strips will be automatically stacked. The steel coil packaging machine will place the strips neatly on the pallet according to the preset stacking plan to facilitate subsequent loading and transportation. The automation of this link greatly saves labor costs and improves the efficiency of stacking.