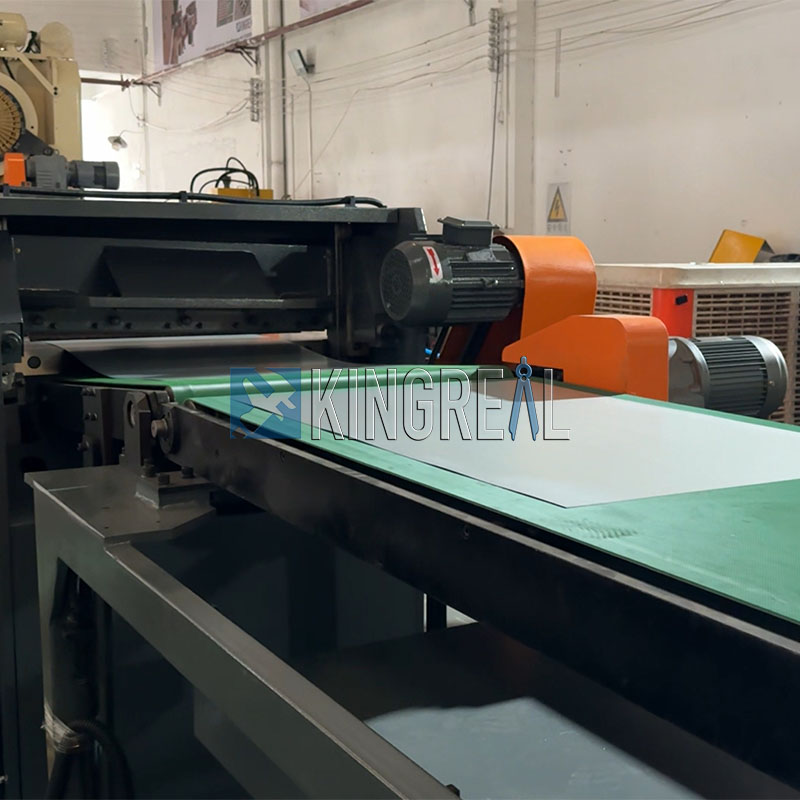

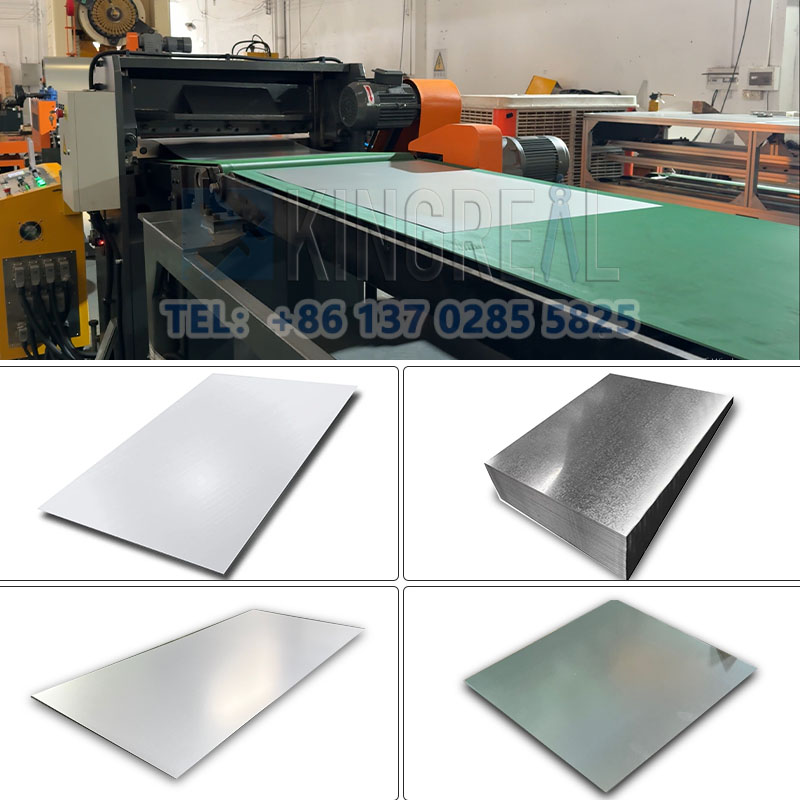

| The compact cut to length machine can accurately shear thin metal coils with a thickness range of 0.2-3mm, and the production speed is 20M/Min. In this article, KINGREAL SLITTING will tell you about the compact cut to length lines in detail. I hope that through this article you can have a deeper understanding of the compact cut to length machine. If you need more information about the compact cut to length lines, please come to consult KINGREAL SLITTING. We have a 24-hour online customer service team to serve you! |  |

Workflow of Compact Cut to Length Machine

Hydraulic decoiler for compact cut to length lines

The hydraulic decoiler is responsible for unwinding the metal coil from the roll to ensure the smooth progress of subsequent processing. It can stably feed the coil into the compact cut to length machine and maintain appropriate tension.

Feeding roller for compact cut to length lines

The feeding roller is responsible for feeding the flattened metal coil into the leveler. The accuracy of feeding directly affects the quality of subsequent shearing.

Leveling machine for compact cut to length line

The leveling machine applies uniform pressure to the metal coil through multiple rollers to eliminate the corrugation and deformation of the coil and ensure its flatness so as to obtain high-quality shearing results.

Shearing machine for compact cut to length lines

The shearing machine is the core component of the compact cut to length line, responsible for accurately shearing the flat metal coil according to the set size. Thanks to advanced shearing technology, the shearing edge is smooth and the error is minimal.

Convey for compact cut to length lines

The sheared metal sheet is automatically transferred to the next link through the conveyor, reducing human intervention and improving work efficiency.

Automatic stack for compact cut to length machine

The sheared metal sheet will be neatly stacked by the automatic stacking device for subsequent processing and storage. This link greatly reduces manual operation and improves work efficiency.

Advantages of Compact Cut to Length Lines

1. Small footprint One of the biggest features of the compact cut to length machine is its small footprint, which is suitable for customers with limited factory space. Compared with ordinary cut to length lines, the components of the compact cut to length lines are smaller, but the functions are equally complete. This enables many small businesses to achieve efficient metal processing in a limited space. 2. Low price and low investment cost The price of the compact cut to length machine is relatively low, and the investment cost is small. It is especially suitable for customers who have just entered this industry or companies with low production requirements. For those customers who want to try metal processing, the compact cut to length lines is undoubtedly a friendly choice. 3. Simple operation The operation of the compact cut to length machine is very simple. The fully automatic design allows users to enter the relevant parameters on the control panel, and the compact cut to length lines will automatically start and complete the shearing. This simple operation method reduces the requirements for operator skills and reduces training costs. 4. With stacking device The compact cut to length machine is equipped with an automatic stacking device. After the shearing is completed, the metal sheets will be automatically stacked. This design not only reduces the manpower demand, but also improves production efficiency, allowing enterprises to focus more on other production links. |  |

Why Do You Need This Compact Cut to Length Lines?

The compact cut to length machine is particularly suitable for customers with low processing output, limited factory area and limited budget. For start-ups or small manufacturers, investing in compact cut to length lines can realize the production process of coil processing at a lower cost. It can help companies complete metal processing tasks efficiently and accurately while avoiding high equipment investment.

In practical applications, the compact cut to length machine not only improves production efficiency, but also ensures product quality and reduces material waste. For those companies that want to stand out in the fiercely competitive market, the compact cut to length lines are ideal choice.

Applications of Compact Cut to Length Machine

The compact cut to length lines has a wide range of uses and is suitable for multiple industries and fields, including but not limited to:

1. Construction industry

In the construction industry, the compact cut to length machine can be used to produce various metal components, such as eaves, walls and other structural parts. These metal materials usually need to be precisely sheared to meet the requirements of architectural design.

2. Home appliance manufacturing

Home appliance manufacturers use compact cut to length lines to produce home appliance shells and internal structural parts. The efficient shearing capacity ensures the smooth progress of mass production while ensuring the dimensional consistency of each component.

3. Automobile industry

In the field of automobile manufacturing, compact cut to length machines are widely used to produce body parts and chassis. Since automobile manufacturing has extremely high requirements for material precision, the professional shearing capacity of compact cut to length lines has been fully utilized.

4. Electronics industry

In the electronics industry, compact cut to length machines can be used to shear metal sheets to produce shells and internal components of various electronic devices. These parts usually require precise shearing and good surface treatment.

In summary, the compact cut to length lines is a metal processing equipment with important uses. It has become the preferred equipment for many companies with its advantages of high efficiency, precision and small footprint. Whether in the construction, home appliances, automobile or electronics industry, the compact cut to length machine can play its unique value.