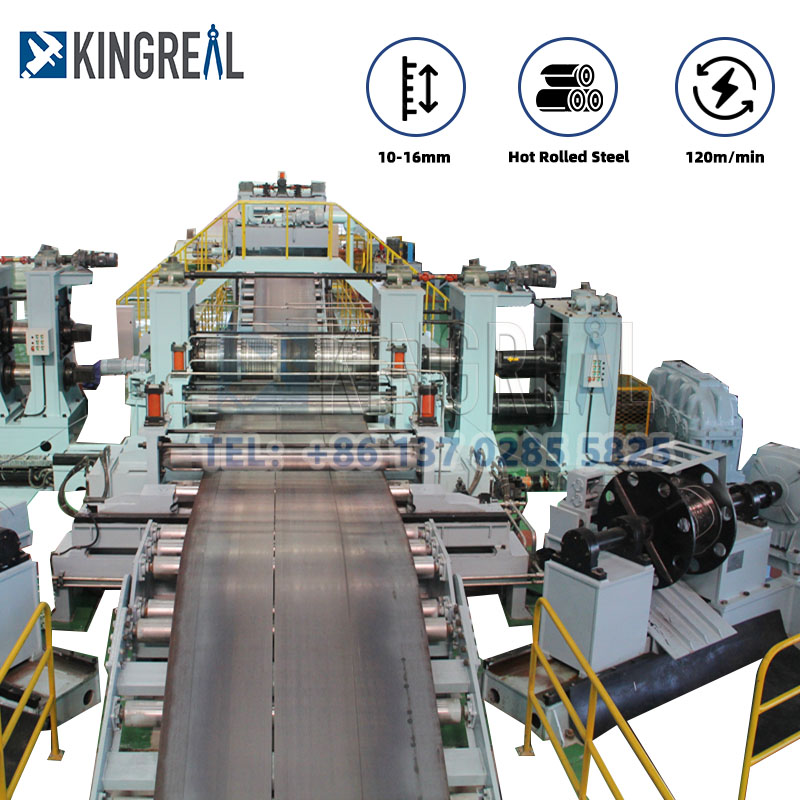

| Hot rolled carbon steel coils are cut into multiple narrower coils to meet customer-specified widths through hot-rolled slitting machines. During the operation of the hot-rolled slitting line, the metal coil passes longitudinally through the circular blade of the hot-rolled slitting machine. For metal sheets, two cylindrical rollers with matching ribs and grooves are used to cut the large coil into multiple narrower coils. The continuous production process of this hot-rolled slitting line is very economical and precise. This article KINGREAL SLITTING will give you a detailed introduction to the working process of the hot-rolled slitting machine. If you are interested in the hot-rolled slitting line and need more pictures, videos, and parameters about it, please consult KINGREAL SLITTING! |  |

Main Components of Hot-Rolled Slitting Machine

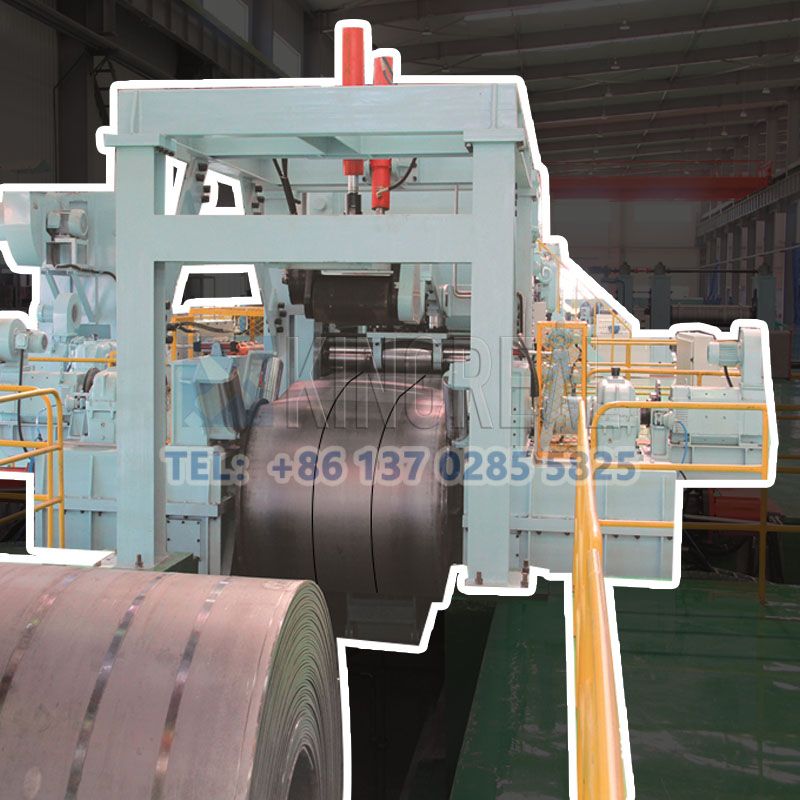

1. Uncoiling for hot-rolled slitting line

Uncoiling is the first step of the hot-rolled slitting line, which involves transferring the coil from the coil saddle to the decoiler. The decoiler is usually equipped with two uncoiling cars:

Coiling car for hot-rolled slitting line: located at the starting end of the hot-rolled slitting line, responsible for quickly and efficiently transporting the coil from the crane to the decoiler.

Decoiler for hot-rolled slitting machine: Located at the end of the hot-rolled slitting line, it is responsible for delivering the slit coils.

During the uncoiling process, the coils are fed into the hot-rolled slitting line under controlled reverse tension to prepare for the subsequent process.

2. Peeling for hot-rolled slitting machine

In the peeling machine of the hot-rolled slitting line, the leading edge of the coil is allowed to bend back to remove the coil group. This process can be completed without manual operation, greatly improving work efficiency.

3. Pinch roller and nip roller for hot-rolled slitting machine

The nip roller is used to smoothly feed the strip when the coil is uncoiled from the decoiler. This step ensures the stability and continuity of the coil and avoids unnecessary interference in subsequent processing.

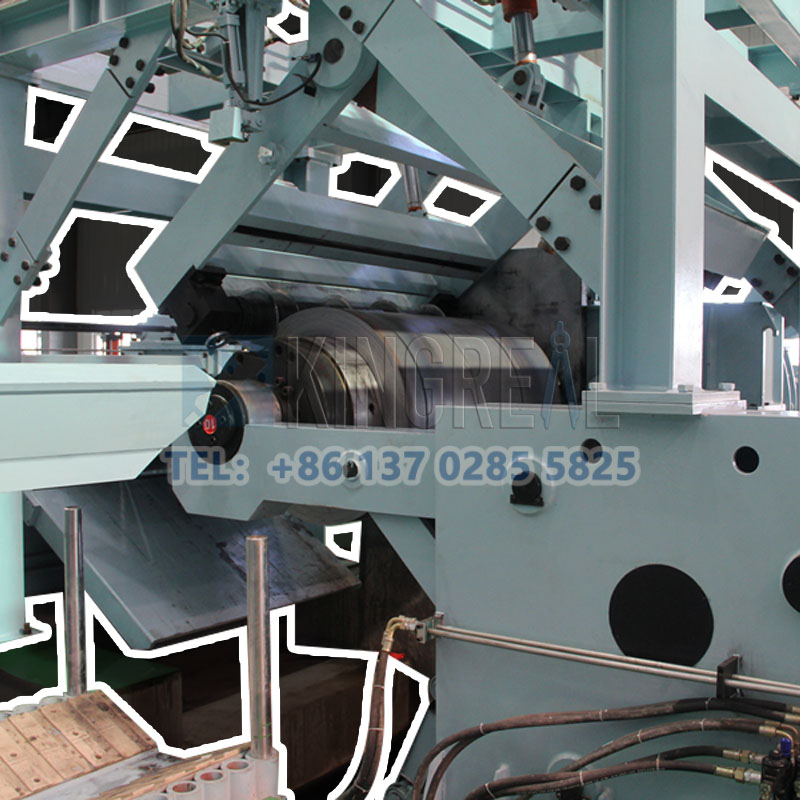

4. Straightening for hot-rolled slitting line

The function of the straightener is to straighten and level the strip and correct the shape with strict tolerances. This step ensures that the shape and size of the coil can meet the customer's requirements during the subsequent slitting process.

5. Slitting for hot-rolled slitting line

In the slitter, the strip is passed through the cutter with a guide table by a pinch roller to ensure that the strip is centered. This is the core process of the hot-rolled slitting line and determines the width and quality of the final product.

6. Side guides for hot-rolled slitting machine

The function of the side guides is to guide the edges trimmed from the slitter to the scrap winder. This step ensures the efficiency of the production process and avoids the waste of scrap.

7. Waste collection device for hot-rolled slitting line

The waste collection device winds the edges trimmed from the slitter into easy-to-handle scrap bundles. This not only helps to keep the working environment clean, but also facilitates the subsequent scrap handling.

8. Tension station for hot-rolled slitting machine

The tension station is a device that automatically maintains a constant unwinding tension as the strip coil gradually descends. The unwinding tension can be adjusted according to the initial outer diameter and thickness of the strip coil to ensure the stability of the slitting process.

9. Recoiler for hot-rolled slitting line

The recoiler with cantilever separator is the workhorse of the hot-rolled slitting machine, responsible for setting the line speed and strip tension. This link directly affects the final quality of the product and production efficiency.

Advantages of Hot-rolled Slitting Line

Hot-rolled slitting machines have significant advantages in the metal processing industry, especially in processing hot-rolled steel.

1. Excellent ductility

Hot-rolled steel has high ductility, making it easier to process during and after rolling. This ductility makes hot-rolled slitting lines perform well in the production process and can handle a variety of complex slitting tasks.

2. Cost-effectiveness

Hot-rolled steel is relatively inexpensive to produce because there are fewer hot-rolling steps. The metal does not need to be cooled before passing through the rollers, and only one rolling pass can significantly reduce the thickness, reducing processing time and energy consumption.

3. Wide range of applications

Hot-rolled steel is most suitable for manufacturing products such as rails and I-beams that have high production volumes and do not require high surface finish. This makes hot-rolled slitting machines an ideal choice for manufacturing these products, meeting the wide needs of the market.

In summary, hot-rolled slitting machines play an important role in the modern metal processing industry with their efficient workflow and many advantages. It can not only meet customers' needs for coils of different widths, but also complete production tasks efficiently and economically.

Based on client designs and particular production requirements, KINGREAL SLITTING offers several hot-rolled slitting machines. For instance, a laminating device, a protective shield, a dual slitter head might all be added to the hot-rolled slitting line. Please do not hesitate to contact KINGREAL SLITTING if you are curious about hot-rolled slitting machines or wish to learn more about it. We will fully offer you professional services and support to help you to greater success in the metal processing sector!