In modern manufacturing, steel cut to length lines are an important metal processing equipment responsible for accurately shearing large rolls of steel into plates of the required length. With the rapid development of global industry, the demand for steel cut to length machines has continued to grow, driving the technological progress and innovation of this industry. In this article, KINGREAL SLITTING will discuss with you the future development trends of steel cut to length lines, including technological innovation, changes in market demand, environmental protection requirements, and progress in intelligent manufacturing.

1. Technological Innovation

High-speed and efficient shearing technology

With the increasing market demand for production efficiency, the technological innovation of steel cut to length machines is moving towards high speed and high efficiency. Traditional shearing methods are often limited by speed and accuracy, while modern steel cut to length lines can complete more shearing tasks in a shorter time by introducing high-speed cutting technology.

For example, with advanced servo drive systems and precision control technologies, steel cut to length machines can achieve rapid response and improve production efficiency. In addition, improvements in tool materials, such as the use of more wear-resistant alloy materials, have also significantly improved shearing speed and quality.

Automation and Intelligence

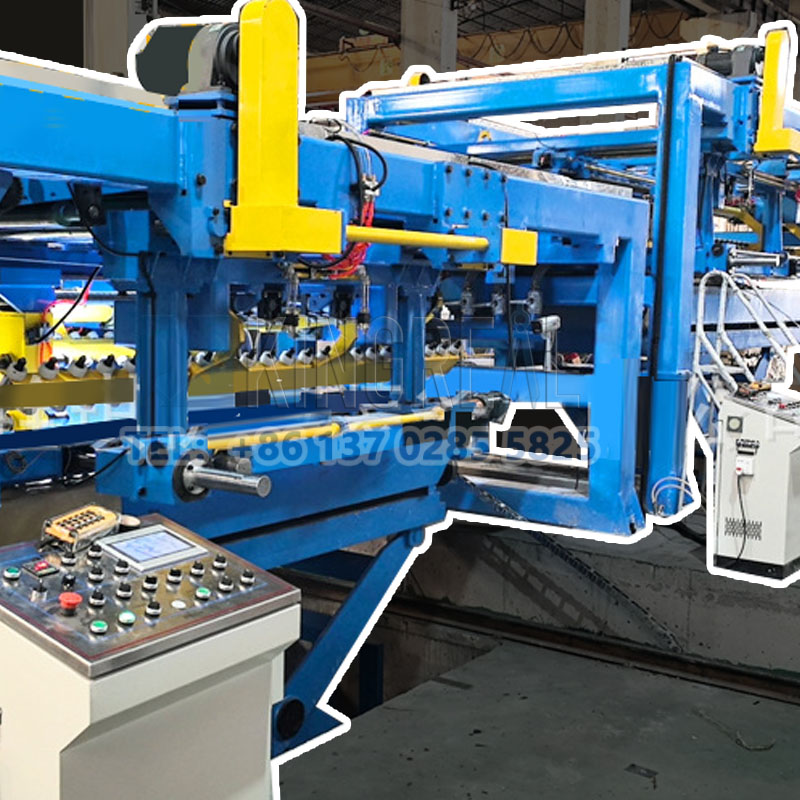

Automation technology is another important trend in the future development of steel cut to length lines. Modern steel cut to length machines are increasingly using automated equipment, such as automatic feeders, laser measurement systems, and robot handling devices. The introduction of these devices has greatly reduced manual operations and improved production efficiency and safety.

In terms of intelligence, steel cut to length lines will combine the Internet of Things (IoT) and big data analysis technology to achieve real-time monitoring and data analysis. Through real-time collection and analysis of production data, enterprises can adjust production parameters in a timely manner, improve production flexibility, reduce waste, and optimize resource allocation.

Precision shearing technology

As industry's requirements for material precision increase, the precision shearing technology of steel cut to length machines is also constantly improving. By improving the shear head design and tool materials, modern steel cut to length lines can achieve higher shearing accuracy while maintaining high shearing speeds.

High-precision shearing not only reduces material waste, but also improves the quality of the final product, which is crucial for customers to gain an advantage in market competition. Therefore, improving the precision of steel cut to length machines will be an important direction for future development.

2. Changes in Market Demand

2.1 Diversified product demand

As the market continues to change, customer demand for steel products is also diversifying. Modern construction, automobile manufacturing, home appliances and other industries have increasingly higher demands for steel of different specifications and thicknesses. This trend has prompted steel cut to length lines to have greater flexibility to adapt to different types of production tasks.

For example, steel cut to length machines should be able to quickly switch production modes and support the shearing of steel of various thicknesses and widths. This flexibility will enable companies to respond quickly to market demand and enhance their competitiveness.

2.2 Growing environmental awareness

As global environmental awareness increases, customers are paying more and more attention to the environmental performance of steel cut to length lines when choosing them. Future steel cut to length machines need to reduce energy consumption and waste generation during production to meet increasingly stringent environmental standards.

Adopting energy-saving technologies and environmentally friendly materials to optimize production processes will be an important direction for the development of steel cut to length machines. For example, many companies are developing motors and drive systems with lower energy consumption to reduce production costs and reduce environmental impact.

3. Advances in Smart Manufacturing

3.1 Application of Industry 4.0

In the context of smart manufacturing, steel cut to length lines will increasingly integrate the concept of Industry 4.0. Through intelligent systems, steel cut to length machines are able to exchange real-time data with other equipment and systems to achieve coordination and optimization of the entire steel cut to length line.

For example, steel cut to length lines can be connected with warehousing systems, production management systems, and supply chain systems to form an intelligent production ecosystem. This integration will improve production efficiency, reduce inventory costs, and enhance customer service levels.

4. Expansion of Global Markets

4.1 The rise of emerging markets

With the development of the global economy, the demand for steel in emerging markets continues to grow, especially in Asia, Africa, and South America. The rapid development of infrastructure construction, manufacturing, and the automotive industry in these markets has provided new growth opportunities for steel cut to length machines.

As a professional steel cut to length line manufacturer, KINGREAL SLITTING will actively expand these emerging markets and provide products and services that meet local needs. By working with local partners, KINGREAL SLITTING will be able to better meet customer needs and expand market share.

4.2 Intensified international competition

With the acceleration of globalization, competition in the steel cut to length machine industry has become increasingly fierce. More international manufacturers have entered the market to provide various types of steel cut to length line solutions. This requires KINGREAL SLITTING to continuously improve product quality and service levels to maintain its competitive advantage.

Through technological innovation, customer service and optimization of marketing strategies, KINGREAL SLITTING will be able to stand out in the fierce market competition and win the trust and support of customers.