With the rapid development of the global manufacturing industry, coil vertical packaging line, as an advanced packaging solution, has attracted more and more attention from the market.

It is designed for the packaging of metal materials such as steel coils, copper coils, wire coils and aluminum coils, providing efficient and reliable automated packaging processes. In this article, KINGREAL SLITTING will introduce the working principle, main components, application areas and significant advantages of vertical coil packing line.

Working Principle of Coil Vertical Packaging Line

The main function of vertical coil packing line is to efficiently package metal coils for easy transportation and storage. The system cooperates with a series of automated equipment to make the entire packaging process smooth and efficient. The following is the workflow of coil vertical packaging line:

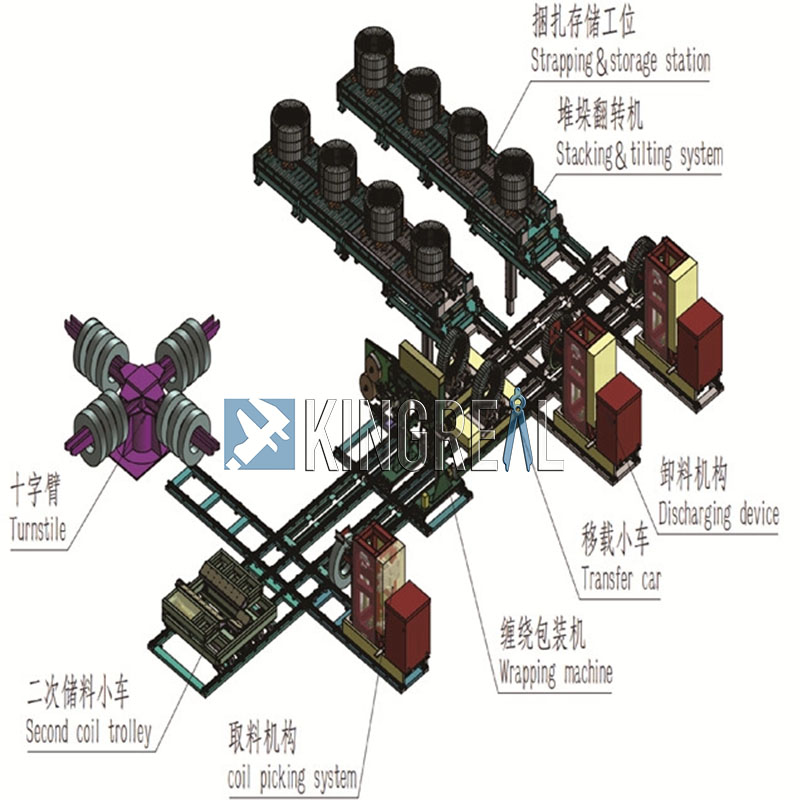

Steel coil revolving gate: The starting point of the vertical coil packing line is the steel coil revolving gate, which is connected to the steel coil trolley and is responsible for automatically loading the slit steel coils. The revolving gate can ensure the stability of the steel coil during loading and reduce the risk of manual operation.

Steel coil trolley: The steel coil trolley is an important component responsible for automatically moving the steel coil for packaging and loading and unloading. Its design makes the transfer of steel coils between different processes efficient and convenient.

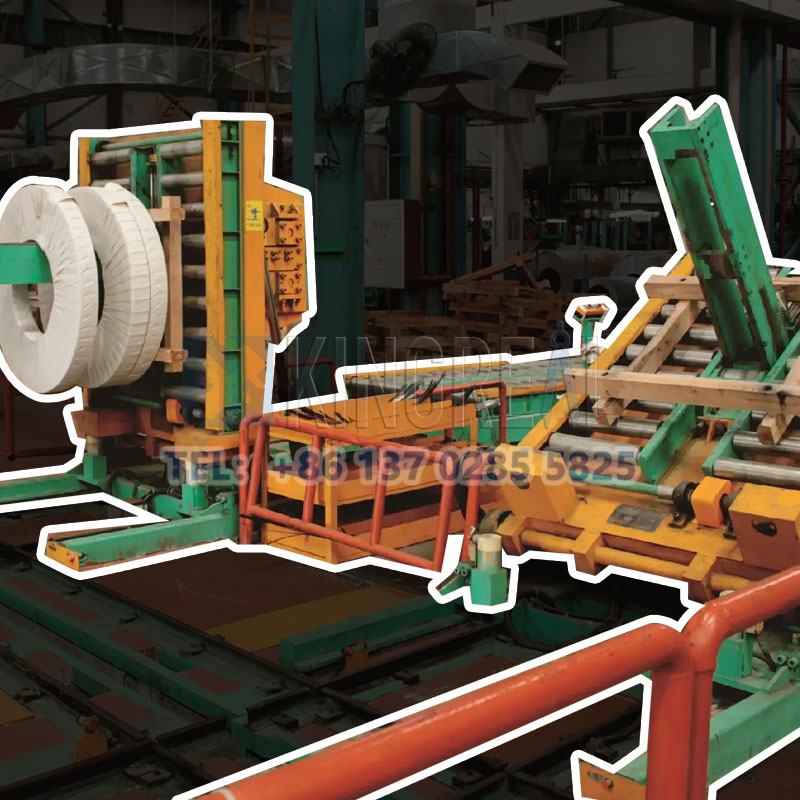

Unloader: The unloader picks up the slit steel coils from the turnstile and changes the steel coils from the vertical conveyor to the horizontal conveyor. This process ensures the integrity of the steel coils during transfer and reduces the possibility of damage.

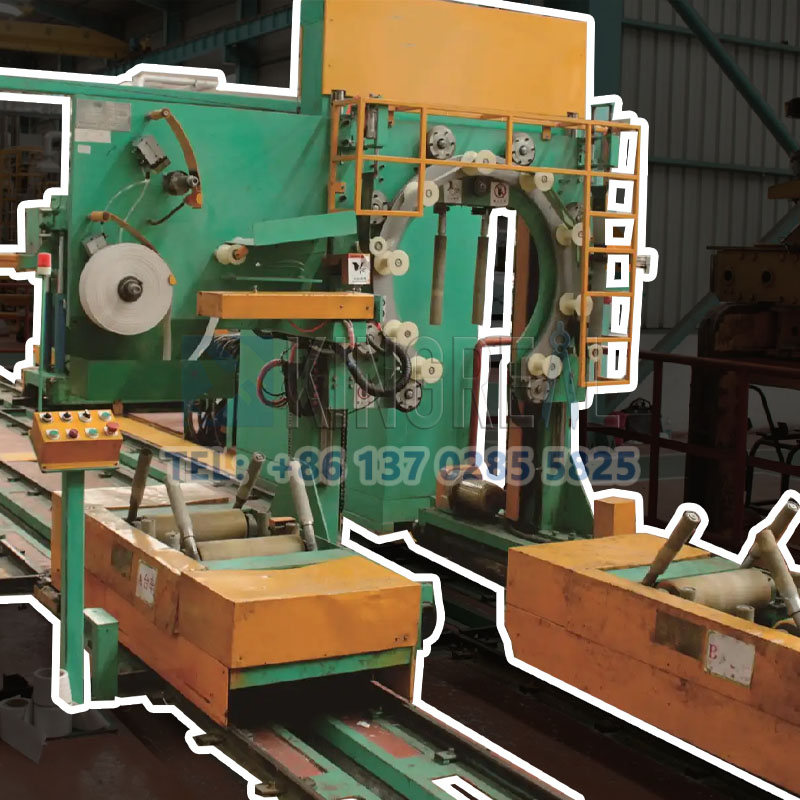

Coil strapping machine: The strapping machine is one of the most important equipment in the vertical coil packing line. It can use PET, PE or steel straps to pass through the inner diameter of the steel coil for strapping, ensuring the stability of the steel coil during transportation and preventing unwinding and damage.

Steel coil wrapping machine: The steel coil wrapping machine uses different packaging materials, such as plastic film or paper, to cross-wrap through the steel coil eye. This wrapping method not only increases the stability of the packaging, but also provides additional moisture protection, ensuring the safety of the coils during transportation and storage.

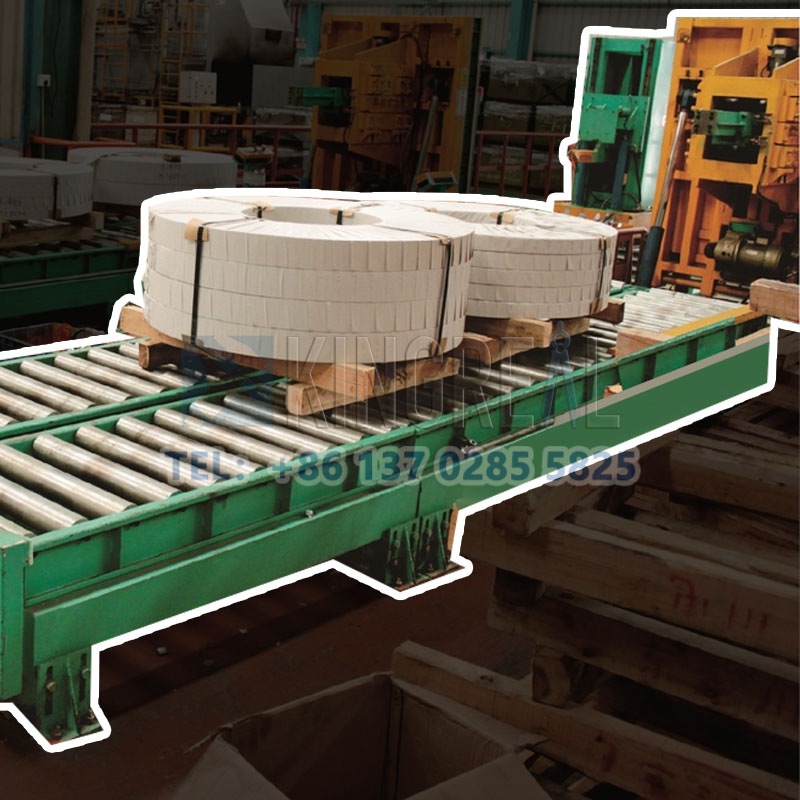

Steel coil palletizer: Finally, the steel coil palletizer is responsible for moving the finished steel coils and stacking the packaged steel coils on pallets. Through automated stacking, the need for manual handling is reduced and storage efficiency is improved.

Application of Coil Vertical Packaging Line

Vertical coil packing line is widely used for packaging of various metal coils. The following are several major application areas:

Copper coil

As an important material for power transformers, the accurate handling and packaging of copper coils is crucial for transportation. The diameter of copper coils usually ranges from 300 to 500 mm and the weight is between 250 and 350 kg. The coil strapping machine of the coil vertical packaging line uses PET straps to firmly strap the copper coils to prevent unwinding during transportation. This not only maintains the integrity of the copper coils, but also minimizes the risk of damage and improves the safety of transportation and warehousing.

In addition, in order to prevent oxidation and maintain the electrical properties of copper, the coil strapping machine also ensures that each copper coil is covered with moisture-proof material. This design significantly improves the safety of copper coils during transportation.

Alloy steel coils

Alloy steel coils occupy a key position in the automotive manufacturing industry. Due to their heavy weight and large size (usually up to 600 mm in diameter and weighing about 500 kg), they require a sturdy handling mechanism. The coil stacker of the vertical coil packing line can efficiently store and retrieve these heavy steel coils, stack them safely on pallets, and significantly reduce labor costs.

The coil strapping machine uses steel straps to ensure that the coils are firmly fixed, reducing the risk of unwinding and potential work-related injuries. In addition, the system can also speed up loading and unloading, improve the overall productivity of the manufacturing process, and help companies achieve higher operational efficiency.

Aluminum Coil

The lightweight and corrosion-resistant properties of aluminum coils make them widely used in construction, transportation, and packaging.

The coil vertical packaging line ensures that the aluminum coils are not damaged during transportation through precise strapping and winding.

Especially in high humidity environments, the use of moisture-proof packaging materials greatly improves the safety of aluminum coils.

Advantages of Coil Vertical Packaging Line

1. High degree of automation

A significant advantage of the vertical coil packing line is its high degree of automation. Through the introduction of automated equipment, the entire packaging process has greatly reduced manual intervention and improved production efficiency and safety. The operator only needs to monitor and maintain the system to ensure the smooth operation of the coil vertical packaging line.

2. Improve the efficiency of the entire slitting process

The vertical coil packing line can be used in conjunction with the metal slitting machine to form a complete production process. This integration not only improves production efficiency, but also reduces the transfer time of materials between different processes, thereby improving overall production capacity. Through this optimized combination, enterprises can quickly respond to market demand and meet customer orders.

3. Quality consistency

The introduction of the automation system ensures the production quality of the coil vertical packaging line. Compared with manual operation, the automation system can achieve higher consistency and reduce quality fluctuations caused by human factors. This advantage enables enterprises to maintain the stability of product quality and win the trust of customers in the fierce market competition.

4. Cost-effectiveness

Although the initial investment may be high, the efficiency and automation of the vertical coil packing line will bring considerable long-term cost benefits. By reducing labor costs, improving production efficiency and reducing material waste, enterprises can achieve higher profit margins. In addition, the maintenance and management costs of the automation system are relatively low, further improving the return on investment.

5. Flexibility and scalability

The coil vertical packaging line is designed with future flexibility and scalability in mind. Enterprises can adjust and upgrade the vertical coil packing line at any time according to changes in market demand. This flexibility enables businesses to remain competitive in an ever-changing market environment.