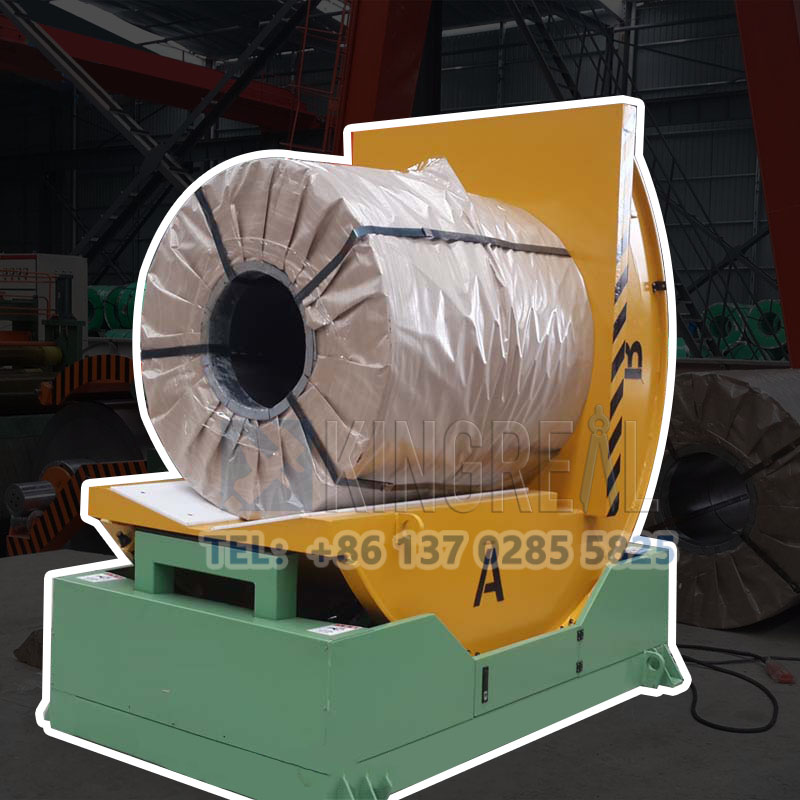

Definition of Coil Tilting Station

A coil tilting station, also known as a coil upender or coil turnover machine, is a device designed to turn a coil from a pallet to an upright position. Its main function is to turn the coil from a horizontal position to a vertical position for subsequent processing and use. The use of a coil tilter station not only improves work efficiency, but also greatly enhances the safety of operation. A high-quality coil tilting station can simplify the dangerous process of turning the coil manually or using an overhead crane, thereby reducing the risk of accidents. |  |

Advantages of Coil Tilter Station

1. Fully controllable coil tilting: higher safety

A significant advantage of a coil tilting station is the high controllability of its tilting process. The operator can control the device to ensure that the coil is always in a safe state when turning. Compared with manual turning or using traditional lifting equipment, a coil tilter station can effectively reduce accidents caused by improper operation. For example, the operator can adjust the tilt angle according to specific needs to ensure that there is no accidental sliding or falling off during the turning process.

2. Quality of the steel coil is fully protected

When using the coil tilting station to turn the steel coil, the design of the coil tilter station can effectively avoid damage to the surface and internal structure of the steel coil. The traditional turning method often causes physical damage to the steel coil such as friction and indentation, while the coil tilting station ensures that the steel coil remains in good condition during the turning process through optimized support and tilting design. This protection can not only extend the service life of the steel coil, but also reduce material waste to a certain extent and improve the economic benefits of the enterprise.

3. Steel coil support design to adapt to a variety of loading methods

The support design of the coil tilter station is very flexible and can adapt to different loading methods. Whether using a forklift or a crane, the coil tilting station can easily complete loading and unloading. This versatility allows the coil tilting station to play its advantages in different working environments, reducing the time waste and reduced efficiency caused by tool mismatch.

4. Equipped with a safe touch edge system to avoid the risk of operators being squeezed

Safety is a top priority in the design of industrial equipment. The moving parts of the coil tilter station are equipped with a safe touch edge system, which can effectively prevent the operator from being squeezed or otherwise injured during operation. When the operator's hands or body come close to the moving parts, the edge contact system immediately stops the operation of the coil tilting station to ensure the safety of the operator. In many industrial environments, operator safety is the primary consideration, and the safety design of the coil tilter station has undoubtedly improved its competitiveness in the market.

Working Principle of Coil Tilting Station

The working principle of the coil tilter station is relatively simple but extremely efficient. The equipment consists of smooth sides and sides with V-shaped saddles. The design of the V-shaped saddle can effectively center the coil and ensure that the coil is always stable during the turning process. The overall workflow is as follows:

Placing the load: The operator uses a forklift or bridge crane to place the load (i.e. steel coil) on the platform of the coil tilting station.

Controlling the tilt: The platform is electrically tilted 90°by a manual control device, which is very easy to operate.

Operation control: The emergency stop controller equipped with three buttons allows the operator to freely move the platform forward and backward at a constant speed, namely tilt, return and emergency stop.

Safety guarantee: During the tilting process, the anti-crushing boundary and the check valve that controls the forward/reverse speed of the platform ensure the safety of operation.

This series of operation processes is not only efficient but also safe, making the coil tilter station widely used in modern manufacturing.

Application Fields of Coil Tilting Station

The coil tilter station is widely used in multiple industries, including but not limited to:

Metal processing industry: In the metal processing industry, the coil tilting station is used to process various steel coils, aluminum coils and other materials. By turning, it is convenient for subsequent cutting, welding and other processes.

Shipbuilding industry: In the shipbuilding process, the coil tilter station is used to process large metal coils to ensure the stability and safety of the materials during the assembly process.

Automobile manufacturing: In the automobile manufacturing industry, the coil tilting station is used to process body materials to ensure processing accuracy and efficiency.

Construction industry: In the construction industry, the coil tilter station is used to process building materials such as steel bars and steel plates to improve construction efficiency and safety.